Mask plate including monitoring pattern and monitoring method

A mask plate and graphics technology, which is applied to the photoplate making process of the pattern surface, the original parts used for photomechanical processing, and instruments, can solve the problems of mask plate quality misjudgment and low yield rate of semiconductor products, and achieve Avoid the loss of product yield and improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

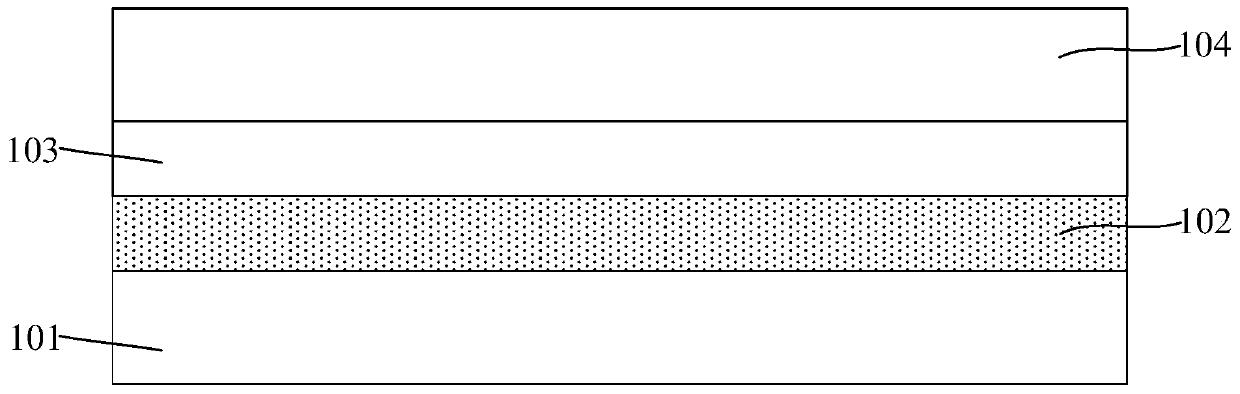

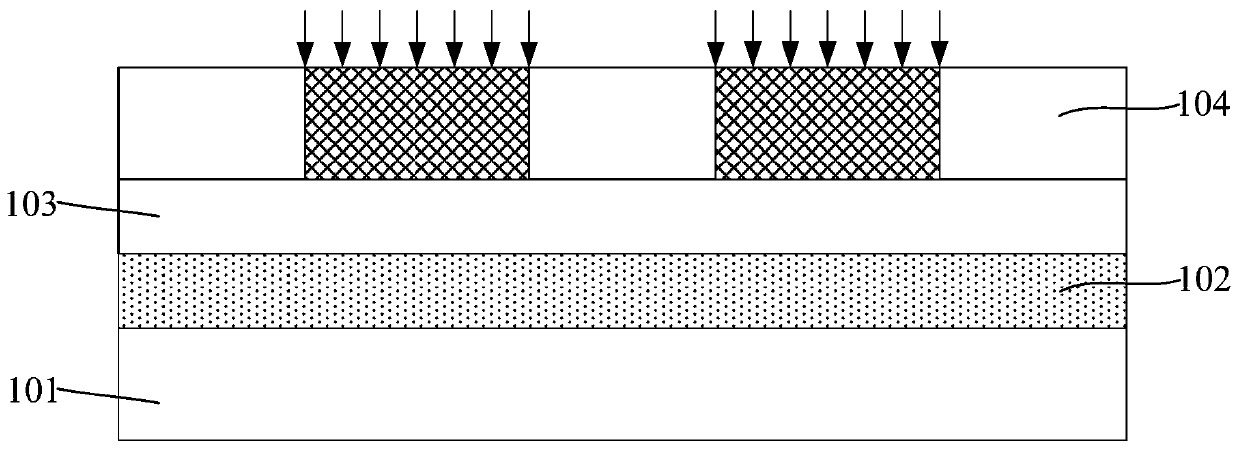

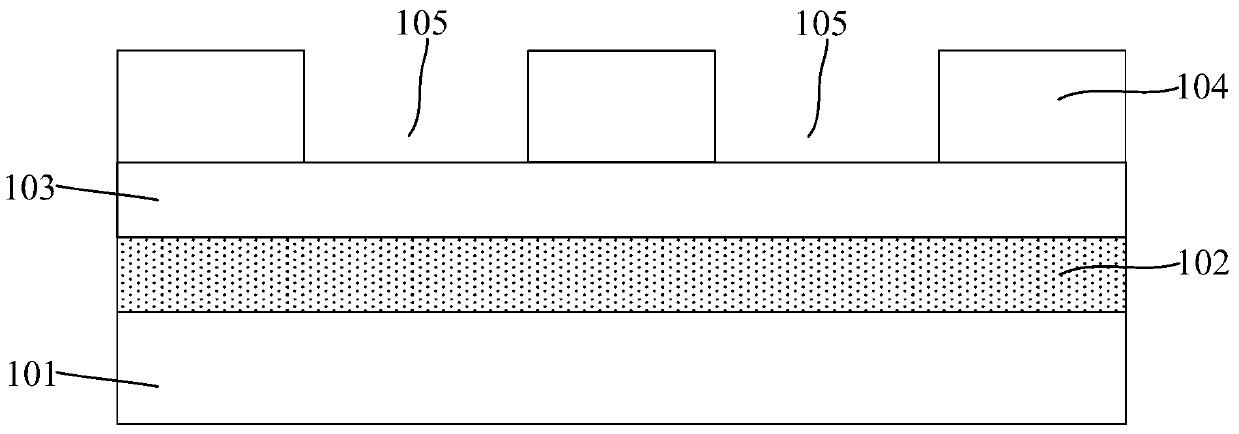

[0035] It can be known from the background art that in the prior art, after the geometrical figure defining the design pattern is formed on the mask plate, the subsequent process of semiconductor manufacturing is performed with the mask plate, which easily brings loss to the product yield.

[0036]After the design pattern is defined in the mask, the monitoring means of the mask is usually to monitor the top view of the mask (mask top view). Specifically, first obtain the top view of the mask with the design pattern defined SEM (Scan Electron Microscope) diagram of the view. When there is no problem with the information displayed in the top view, it is determined that the manufactured mask meets the requirements, and the design pattern in the mask is determined to be free of defects, so the manufactured mask can be put into the subsequent semiconductor process flow.

[0037] After analysis, it was found that in mask manufacturing, even if the information displayed in the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com