Radiation brightness compensation type heat radiation infrared light source system and method

A technology of radiance and infrared light source, which is applied in control/regulation systems, light control, instruments, etc., can solve the problems of infrared light source spectral radiance output changes, spectral radiance stability, self-aging, etc., to achieve good The effect of stability and noise immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

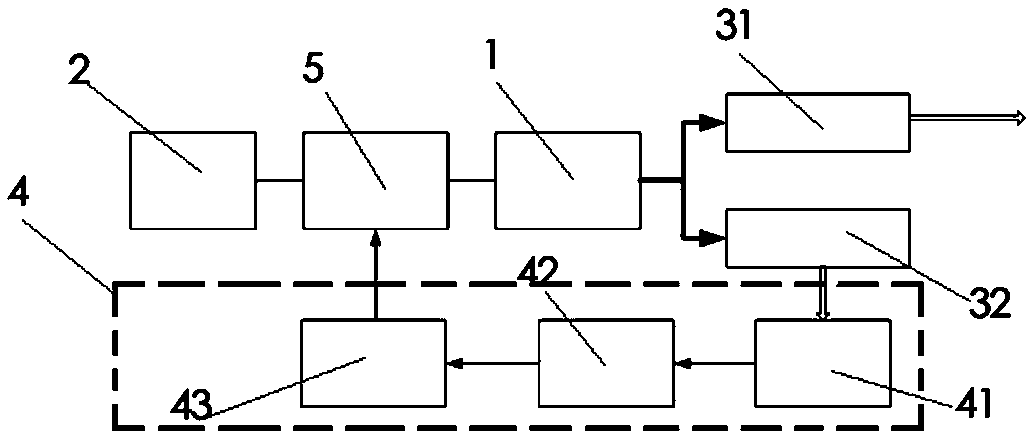

[0014] Attached below Figure 2-3 Further technical description of the present invention:

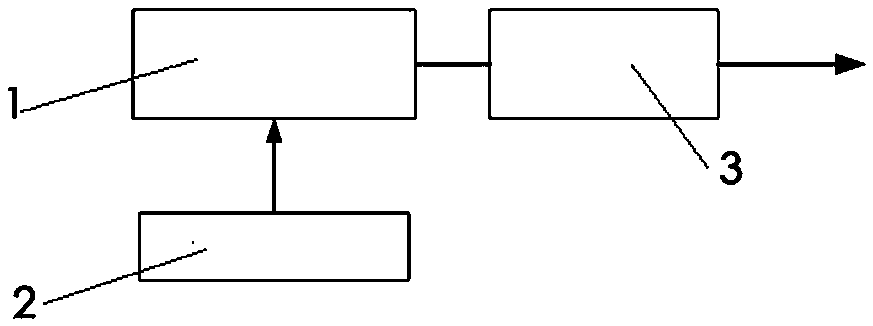

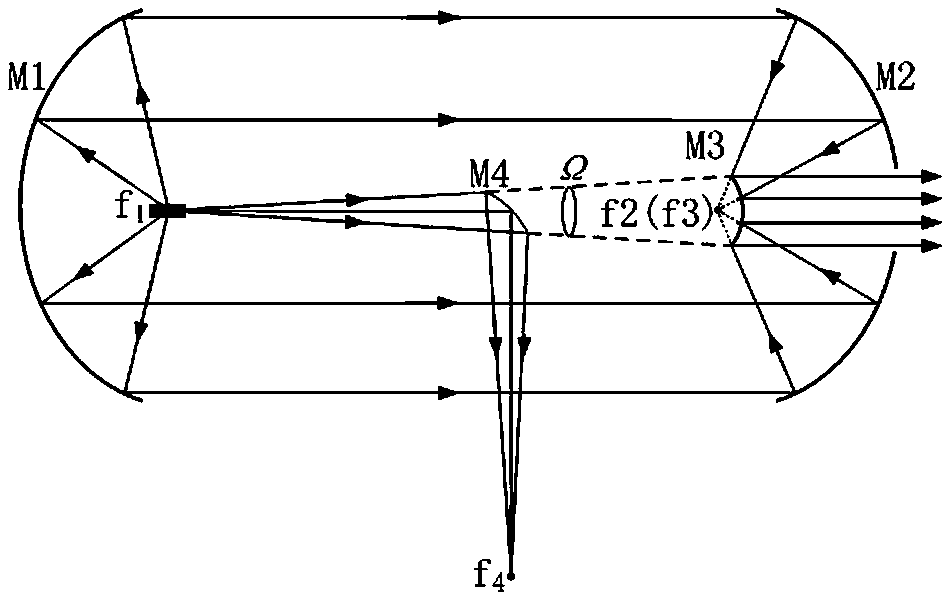

[0015] Such as Figure 2-3 As shown, the system of the present invention includes a ceramic heating element 1, an adjusting optical path 3 and a constant current power supply 2, and the adjusting optical path is composed of an output optical path 31 and a measuring optical path 32. Electric energy is converted into heat energy under the action of electric current. Most of the spectral radiation emitted by the ceramic heating element 1 is adjusted to parallel output radiation through the output optical path 31. At the same time, a small part of the spectral radiation is converged by the measuring optical path 32 and projected on the infrared detector 41. The infrared detector 41 photoelectrically converts it into a weak electrical signal, and after being shaped, filtered, and amplified by the signal processing circuit 42, it enters the compensation controller 43, and the compensation co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap