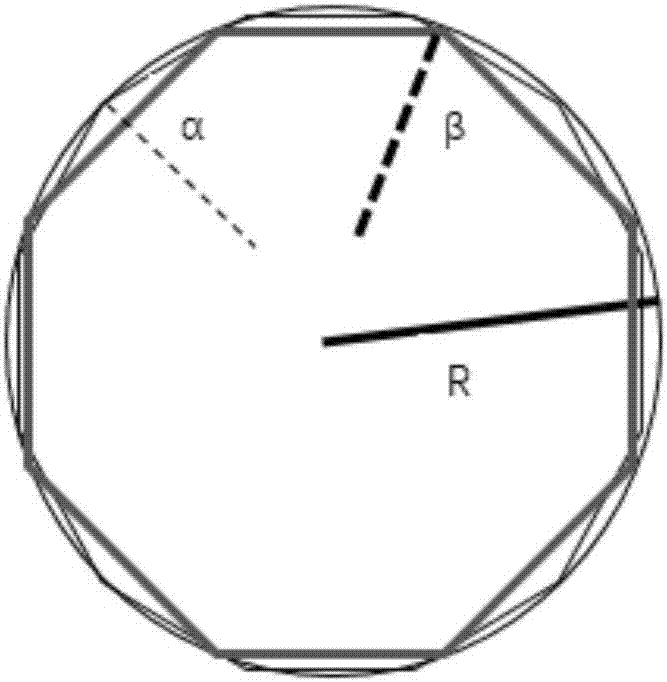

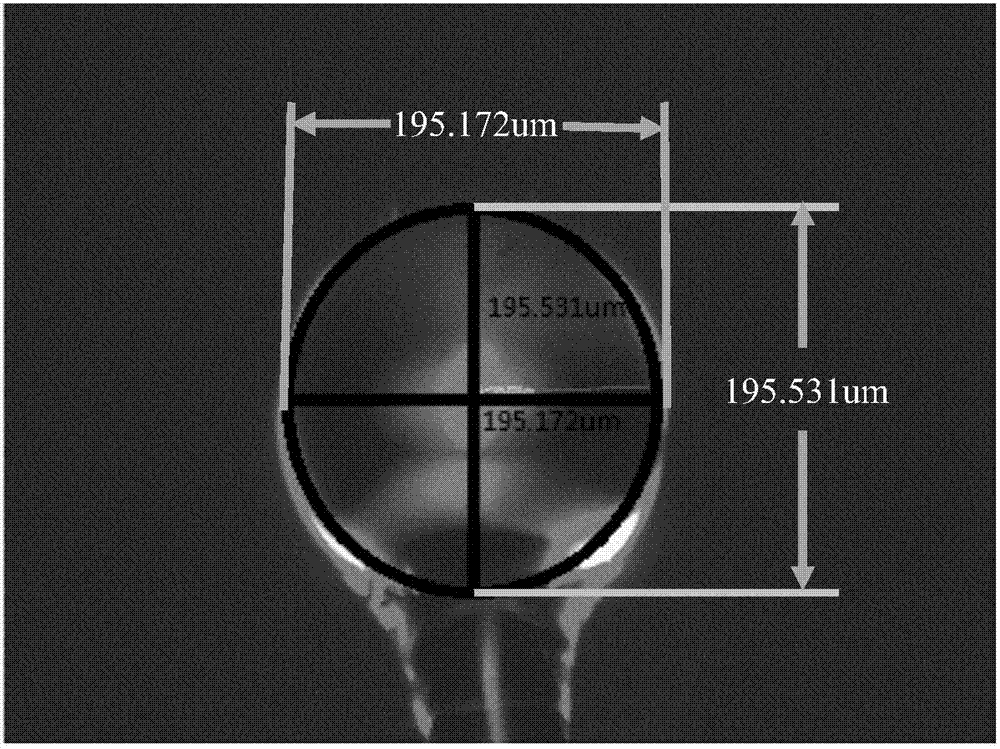

Single-frequency narrow-band optical fiber laser based on high roundness three-dimensional rotational symmetric microcavity

A fiber laser, three-dimensional rotation technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of high production cost, wide output bandwidth, poor stability, etc., achieve simple structure, reduce high-order modes, and improve Q value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

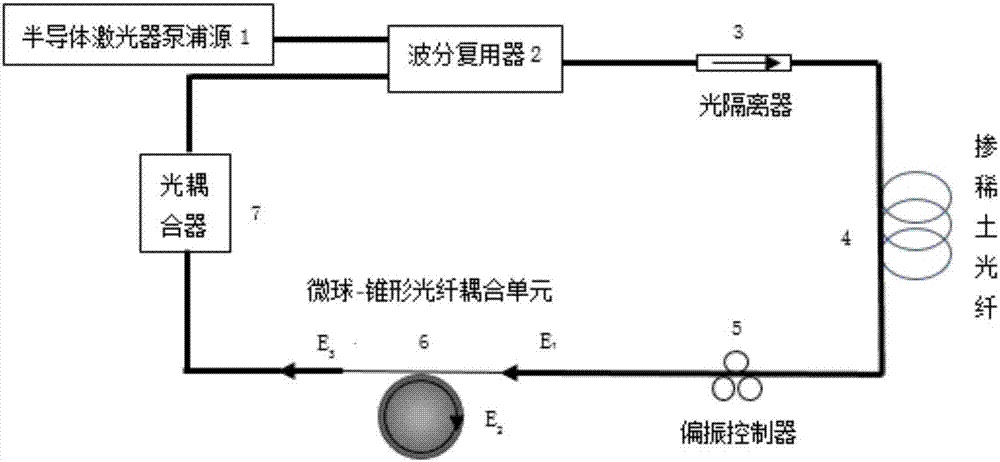

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The fiber laser proposed by the present invention has a structure comprising: a semiconductor laser pump source, a wavelength division multiplexer, an optical isolator, a rare earth-doped optical fiber, a polarization controller, a high-roundness microsphere cavity-tapered optical fiber coupling unit, and an optical fiber laser. Coupler; the pumping source of the semiconductor laser is connected to the optical isolator through the wavelength division multiplexer, and the output end of the optical isolator is connected to the rare earth-doped optical fiber, and the output end of the rare earth doping is sequentially passed through the polarization controller, high Symmetrical microsphere cavity-tapered optical fiber frequency selection unit, optical coupler, and finally the output end of the optical coupler is connected with the input end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com