Integrative device and method for flue gas denitration at low temperature

A technology for flue gas and denitrification, which is applied in the field of low-temperature flue gas denitrification devices and integrated devices for low-temperature flue gas denitrification, which can solve the problems of low oxidation efficiency and achieve enhanced oxidation effects, slow rising speed, and no secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

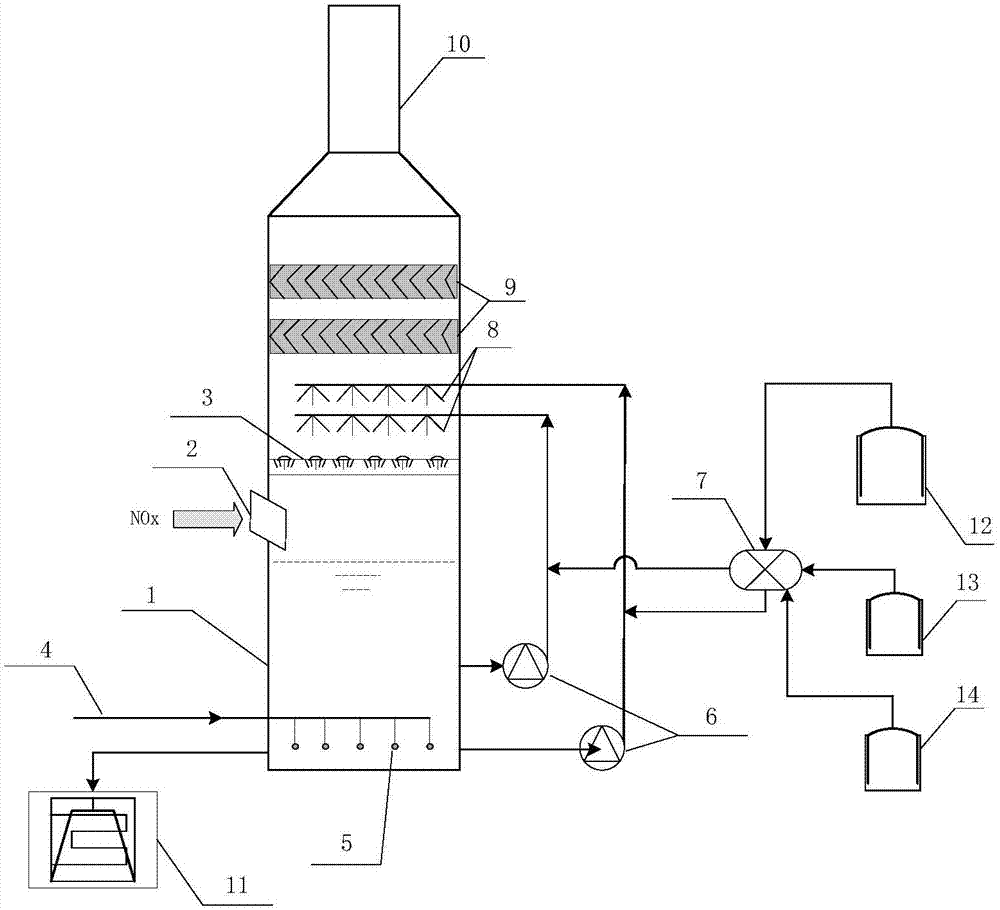

[0050] See figure 1 , which is a structural schematic diagram of an integrated device for flue gas low-temperature denitrification in this embodiment, which includes an absorption tower 1, an aeration pipeline 4, a mixer 7, a hydrogen peroxide storage tank 12, a potentiator storage tank 13, and a synergist storage tank 14. Spray system, demister 9, cyclone 3, micro-nano bubble generator 5, said spray system includes circulation pump 6 and spray device 8:

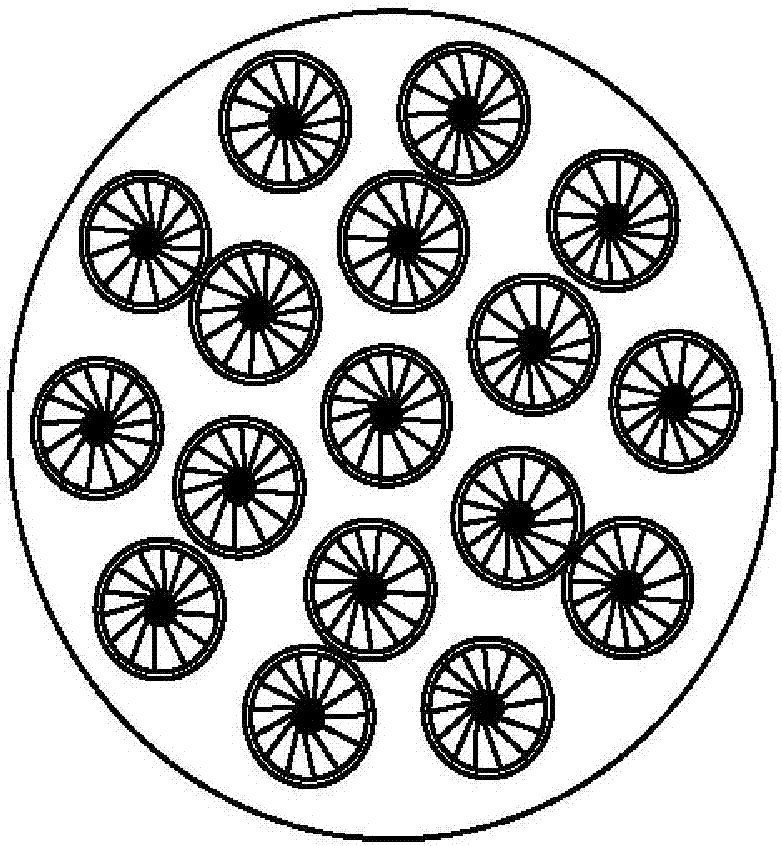

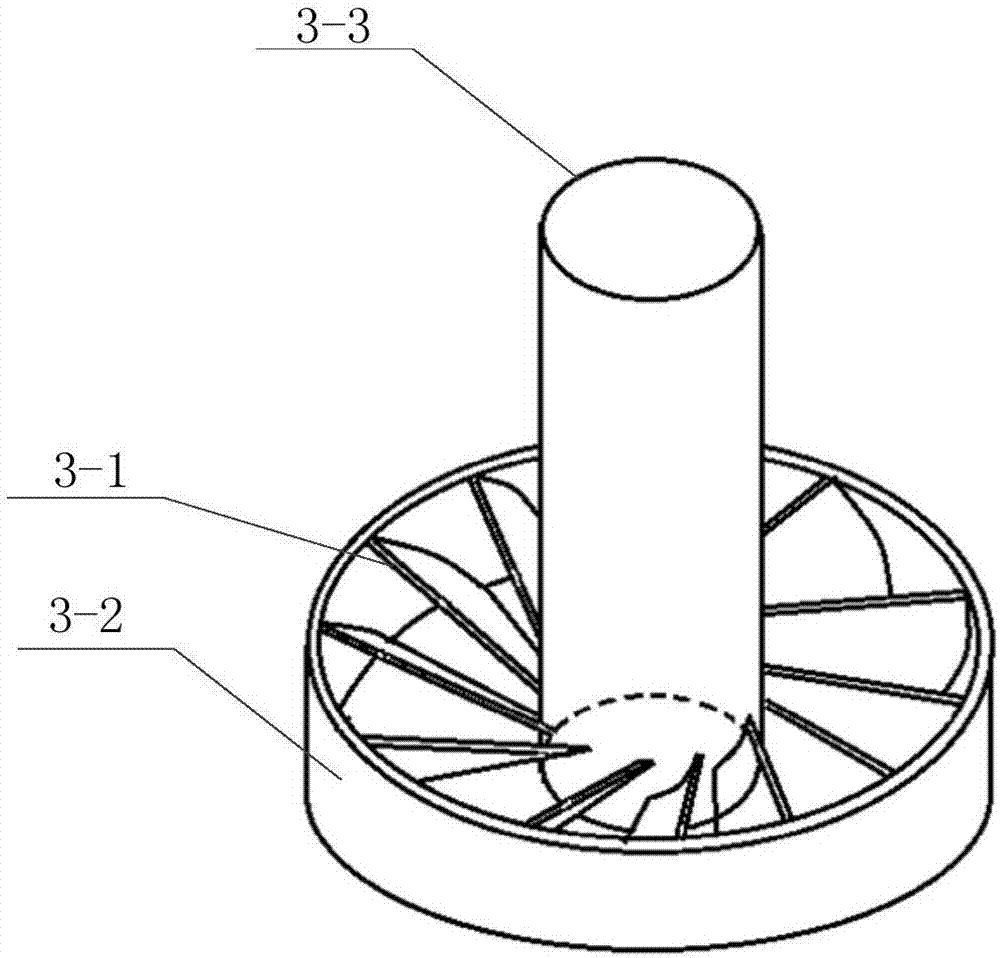

[0051] See figure 2 and image 3 , which are respectively the top view of the cyclone and the schematic diagram of the cyclone cylinder of the cyclone, the cyclone 3 includes a plurality of cyclone cylinders arranged side by side, each cyclone cylinder is composed of a guide vane 3-1, a cylinder wall 3-2 It is composed of the central column 3-3; the outer side of the guide vane 3-1 is fixedly connected to the cylinder wall 3-2, and the inner side is fixedly connected to the central column 3-3;

[0052] The tower body of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com