Apparatus for combined processing of high-salinity high-COD sewage and processing method

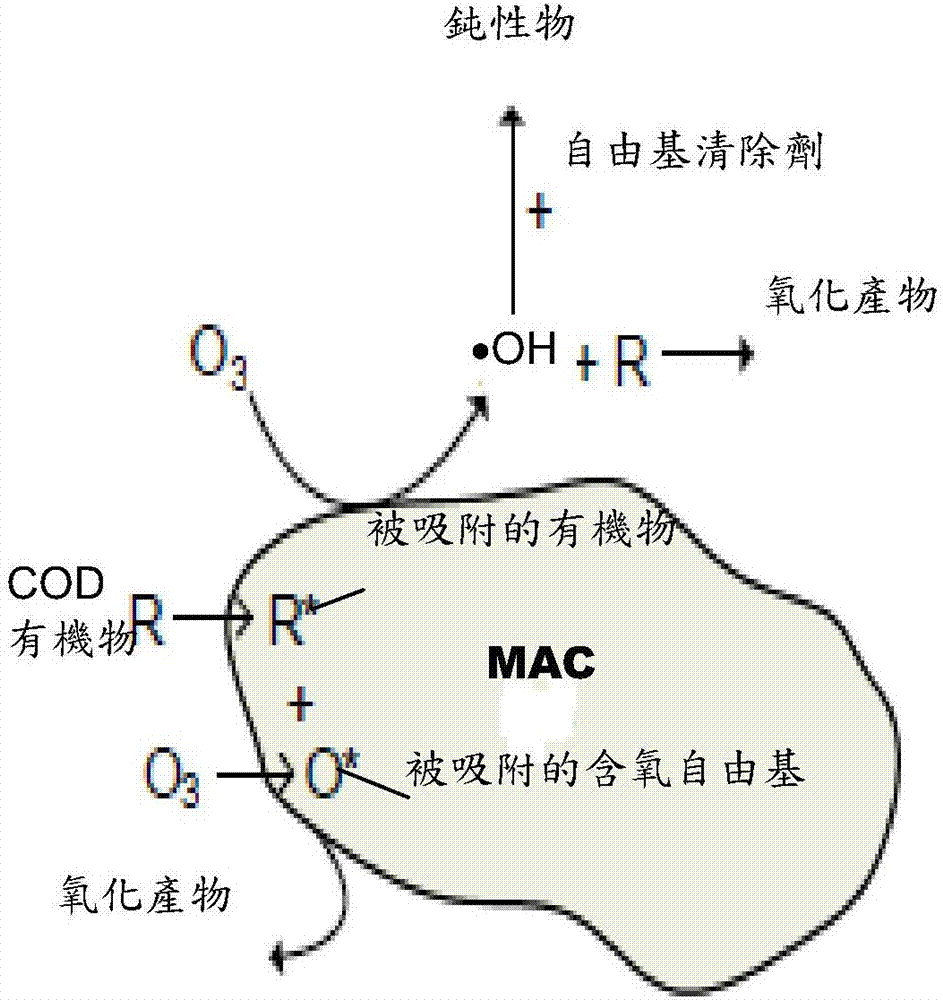

A sewage and high-salt technology, applied in chemical instruments and methods, combustion methods, water/sewage treatment, etc., can solve the problems of standard treatment, difficult regeneration, and easy saturation of physical adsorption technology, and achieve the effect of reducing the demand for regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

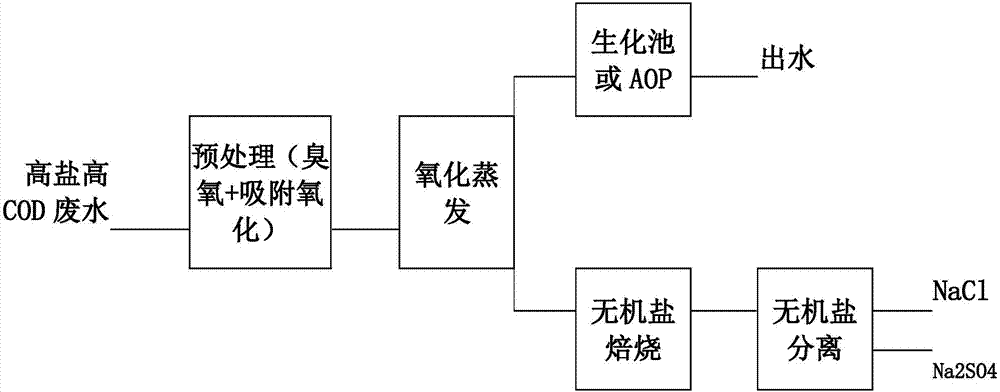

Method used

Image

Examples

Embodiment Construction

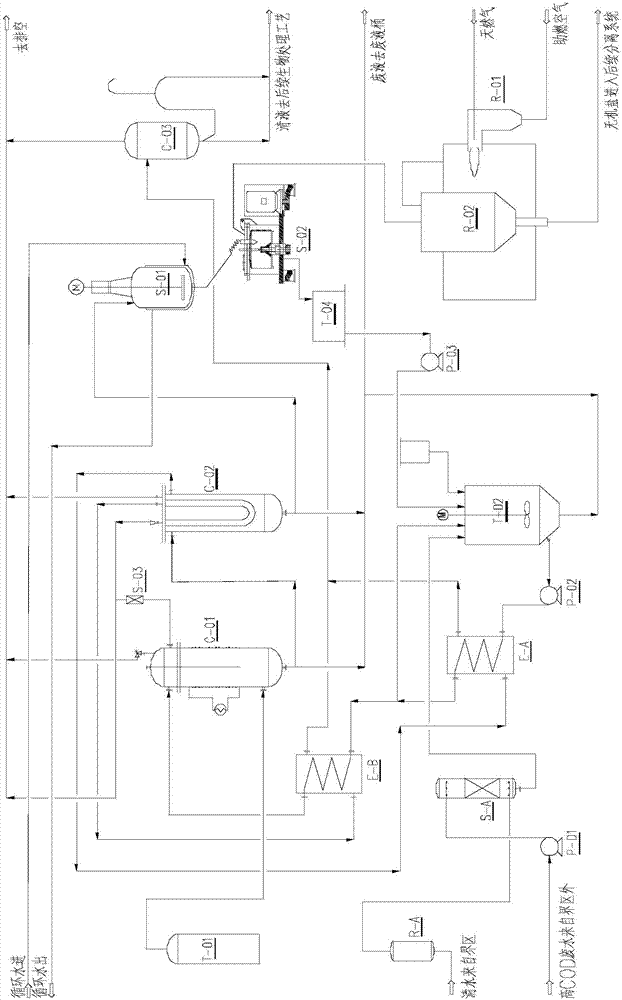

[0030] Such as image 3As shown, the device of the present invention includes: ozone generator EO3 (R-A), MAC packed tower (S-A), preheater A (E-A), preheater B (E-B), pH adjustment reaction tank (T-02), Centrifugal liquid storage tank (T-04), centrifugal separator (S-02), roaster (R-02), condensate gas-liquid separator (C-03), burner (R-01), oxidation evaporation reactor (C-01), demister (S-03), tower top gas condenser (C-02), cooling crystallizer (S-01), pumps, pipelines, etc., it is characterized in that: the sewage pool passes through a pipeline and The pump is connected to the upper inlet of the MAC packed tower; the EO3 ozone outlet of the ozone generator is connected to the aeration port at the lower part of the MAC packed tower through a pipe and the pump; the sewage outlet at the lower part of the MAC packed tower is connected to the sewage inlet of the pH adjustment reaction tank through a pipe; the pH adjustment The reaction tank is equipped with a PH adjustment ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com