Method for purifying piggery fermentation wastewater by using Chlorella

A technology for fermenting waste water and chlorella, applied in the direction of using microorganisms, chemical instruments and methods, methods based on microorganisms, etc., can solve the problems of polluting the environment and not being economical, and achieve the effect of directly discharging polluted environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

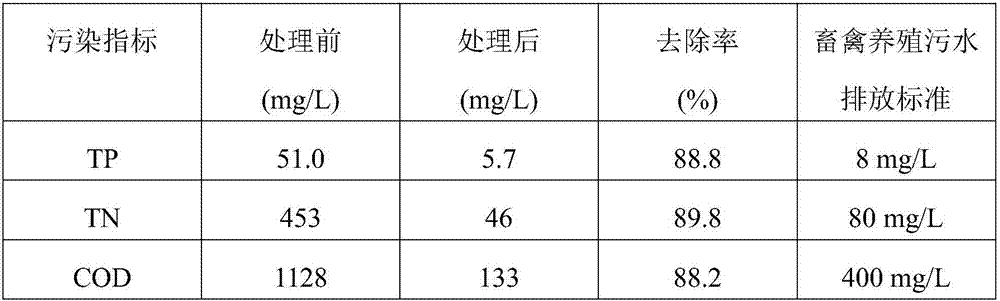

Examples

Embodiment

[0019] (1) After solid-liquid separation of pig farm fermentation wastewater, the clear liquid enters the aeration tank for aeration. After 48h aeration, it enters the sedimentation tank. The precipitation time is 2h. The supernatant enters the disinfection tank with 15g / m 3 Disinfect with strong chlorinate, aerate for 30min after 16h, add sodium thiosulfate 2.5 times the mass of strong chlorinate to neutralize, then enter the regulating tank to adjust the pH to 7 and use tap water to adjust the wastewater concentration.

[0020] (2) The fermented wastewater of the pig farm after the above treatment starts from a low concentration, and in turn domesticates chlorella in wastewater with a concentration of 20-100% by volume. The chlorella is cultivated on a shaker in a constant temperature culture room. The temperature is 23-26°C, the rotating speed of the shaker is 180rmp / min, and the illumination is 3000-4000lux. Finally, the algae species that can grow rapidly in the fermentation w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com