Technology and device for producing zinc acetylacetonate with solid phase method

A technology of zinc acetylacetonate and solid-phase method, applied in chemical instruments and methods, preparation of aldehyde/ketone chelates, chemical/physical/physical-chemical stationary reactors, etc., can solve the problem of large water consumption, low production capacity and pollution It can reduce the cost of wastewater treatment, reduce energy consumption and cost, and simplify the operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

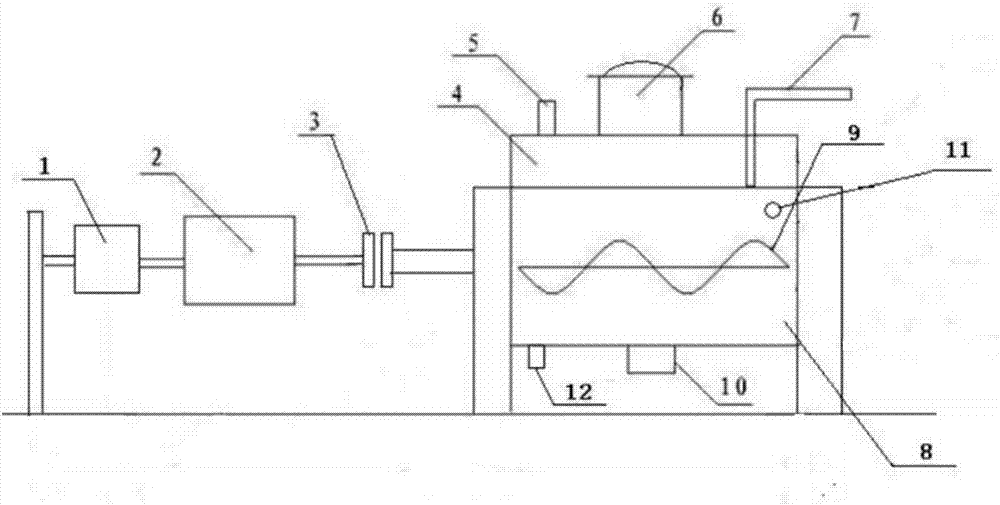

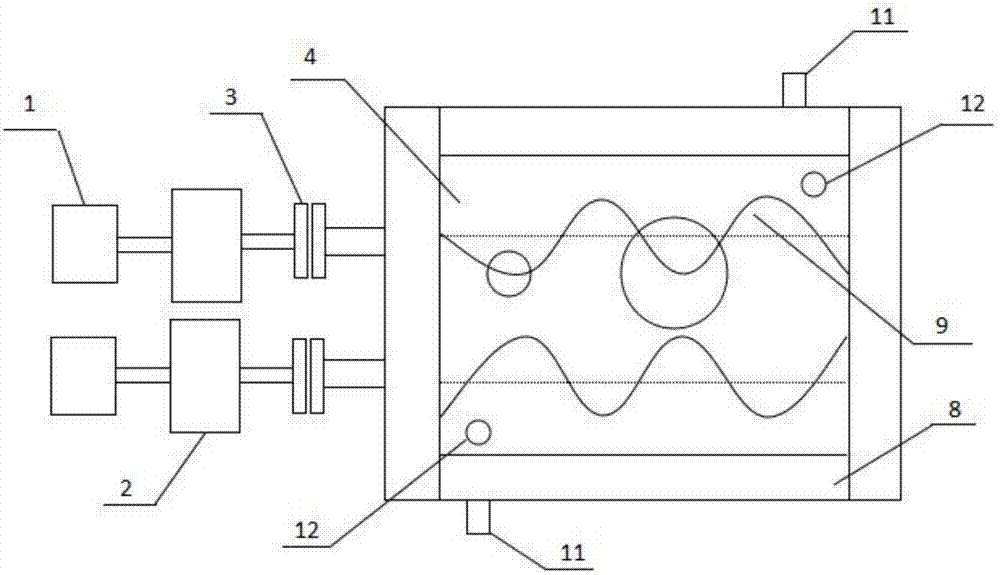

[0028] Example 1: Reaction raw materials: 1500 g of acetylacetone (99.8% content), 630 g of zinc oxide (99.8% content), 1800 g of deionized water.

[0029] First, add zinc oxide and deionized water into the reaction vessel (4) from the feeding port (6), turn on the stirring paddle (9), wait until the zinc oxide and water are fully mixed into a thin paste, slowly add acetylacetone, and continue stirring, After fully shearing and stirring for 2 hours. Close the reaction vessel, open the steam valve and the vacuum valve, and continue stirring and drying for 2 hours at a temperature of 30-60° C. under a negative pressure of 0-0.1 MPa. Water vapor is discharged from the gas outlet pipe (7), and after the drying is completed, the steam valve and the vacuum valve are closed. Coarse powder was obtained after reaction and drying, which was pulverized by a pulverizer to obtain 1931.15g of zinc acetylacetonate (calculated as dry product), which should be 1968.56g according to theoretica...

Embodiment 2

[0033] Example 2: Reaction raw materials: acetylacetone 2000g (content 99.7%), zinc oxide 780g (content 99.7%), deionized water 2000g.

[0034]First, add zinc hydroxide and deionized water into the reaction vessel (4) from the feeding port (6), turn on the stirring paddle (9), wait until the zinc oxide and water are fully mixed into a thin paste, slowly add acetylacetone, and continue stirring , after fully shearing and stirring for 2 hours. Close the reaction vessel, open the steam valve and the vacuum valve, and keep stirring and drying for 2.5 hours at a temperature of 30-60° C. under a negative pressure of 0-0.1 MPa. Water vapor is discharged from the gas outlet pipe (7), and after the drying is completed, the steam valve and the vacuum valve are closed. Coarse powder was obtained after reaction and drying, which was pulverized by a pulverizer to obtain 2574.90g of finished zinc acetylacetonate (calculated as dry product), which should be 2622.11g according to theoretical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com