Technology and device for producing calcium acetylacetonate with solid phase method

A technology of calcium acetylacetonate and solid-phase method, which is applied in chemical instruments and methods, aldehyde/ketone chelate preparation, chemical/physical/physicochemical stationary reactors, etc., and can solve the problems of large water consumption, low production capacity, energy High energy consumption and other problems, to achieve the effect of reducing waste water treatment costs, reducing energy consumption and costs, and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

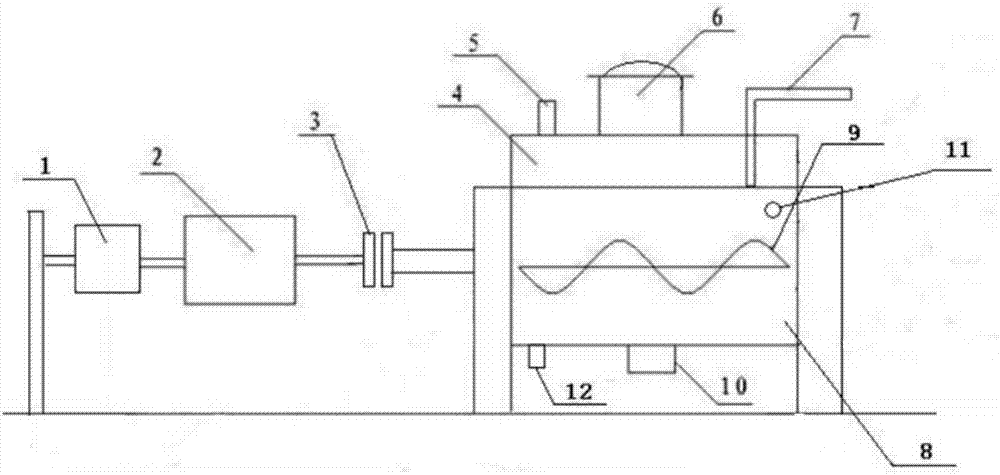

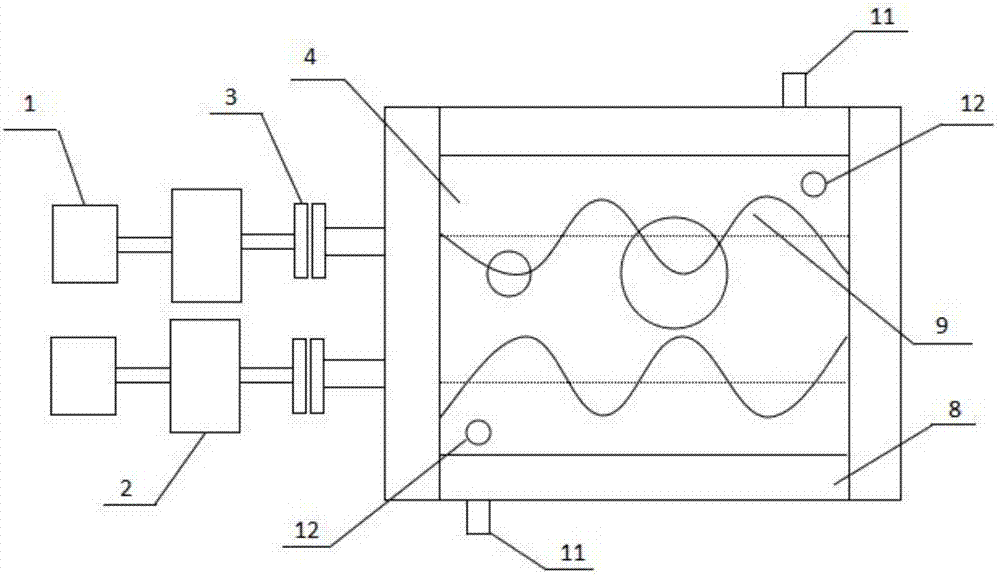

[0028] Example 1: Reaction raw materials: acetylacetone 1600g (content 99.8%), calcium hydroxide 620g (content 99.2%), deionized water 1800g.

[0029] First, calcium hydroxide and deionized water are added to the reaction vessel 4 from the feeding port 6, and the stirring paddle 9 is turned on. After the calcium hydroxide and water are fully mixed into a thin paste, slowly add acetylacetone, continue to stir, and fully shear and stir After 2 hours of reaction. Close the reaction vessel, open the steam valve and the vacuum valve, and continue stirring and drying for 2 hours at a temperature of 50-80° C. under a negative pressure of 0-0.1 MPa. The water vapor is discharged from the gas outlet pipe 7, and after the drying is finished, the steam valve and the vacuum valve are closed. After the reaction and drying, the coarse powder was obtained, which was pulverized by a pulverizer to obtain 1871.69 g of calcium acetylacetonate (calculated as dry product), which should be 1900.19...

Embodiment 2

[0033] Example 2: Reaction raw materials: acetylacetone 2000g (content 99.7%), calcium hydroxide 769g (content 96.5%), deionized water 2000g.

[0034]First, calcium hydroxide and deionized water are added to the reaction vessel 4 from the feeding port 6, and the stirring paddle 9 is turned on. After the calcium hydroxide and water are fully mixed into a thin paste, slowly add acetylacetone, continue to stir, and fully shear and stir After 2 hours of reaction. Close the reaction vessel, open the steam valve and the vacuum valve, and keep stirring and drying for 2.5 hours at a temperature of 50-80°C under a negative pressure of 0-0.1 MPa. The water vapor is discharged from the gas outlet pipe 7, and after the drying is finished, the steam valve and the vacuum valve are closed. Coarse powder was obtained after reaction and drying, which was pulverized by a pulverizer to obtain 2351.50 g of calcium acetylacetonate (calculated as dry product), which should be 2372.86 g according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com