White emulsion adhesive and preparation method thereof

An adhesive, white latex technology, applied in the direction of adhesive additives, monocarboxylic acid ester copolymer adhesives, adhesive types, etc., can solve the problems of easy freezing, large equipment investment, poor water resistance and moisture resistance, etc. Achieve high tensile and shear strength, low cold junction temperature and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

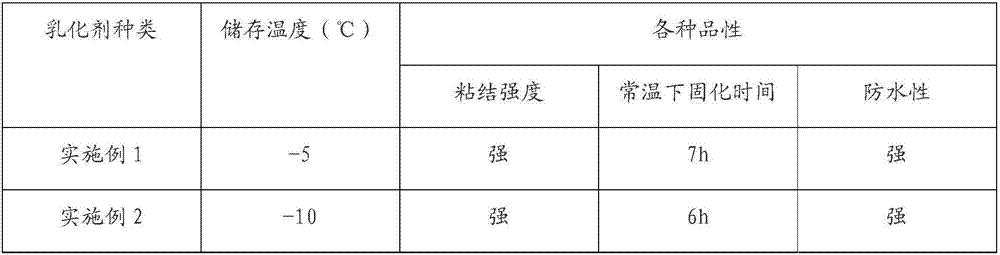

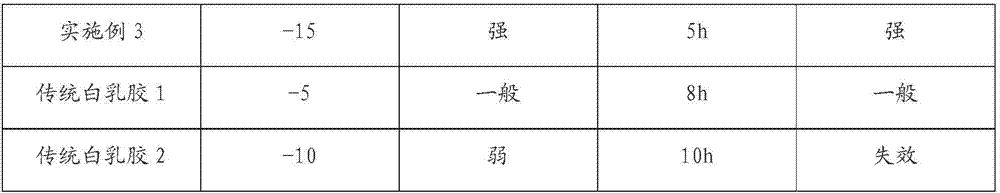

Examples

Embodiment 1

[0015] White latex adhesive, comprising 400 parts of polyvinyl alcohol, 8 parts of hydrochloric acid, 50 parts of sodium tripolyphosphate, 9 parts of liquid caustic soda, 13 parts of emulsifier, 15 parts of dibutyl phthalate, 460 parts of polyvinyl acetate by weight Parts, 250 parts of fillers, 3.5 parts of triethanolamine oleate.

[0016] Among them, the emulsifier is OP-10 or TX-10; the filler is talcum powder, titanium dioxide or lithopone.

[0017] The preparation method of white latex adhesive of the present invention: comprise the following steps:

[0018] Step 1: Dissolve polyvinyl alcohol in water at 90°C, adjust the pH value to 2.5 with hydrochloric acid, keep the temperature at 90°C, add sodium tripolyphosphate under stirring, react for 1 hour, cool down to below 50°C, add liquid Alkali to adjust the pH to 7;

[0019] Step 2: Under stirring, keep the temperature at 50°C, add emulsifier and dibutyl phthalate, keep warm at 45°C for 1h and stir, then cool to room temp...

Embodiment 2

[0023] White latex adhesive, comprising 330 parts of polyvinyl alcohol, 7 parts of hydrochloric acid, 45 parts of sodium tripolyphosphate, 7.5 parts of liquid caustic soda, 13 parts of emulsifier, 14 parts of dibutyl phthalate, 500 parts of polyvinyl acetate by weight part, 300 parts of filler, 2 parts of triethanolamine oleate.

[0024] Among them, the emulsifier is OP-10 or TX-10; the filler is talcum powder, titanium dioxide or lithopone.

[0025] The preparation method of white latex adhesive of the present invention: comprise the following steps:

[0026] Step 1: Dissolve polyvinyl alcohol in water at 95°C, adjust the pH value to 2 with hydrochloric acid, keep the temperature at 95°C, add sodium tripolyphosphate under stirring, react for 1 hour, cool down to below 50°C, add liquid Alkali to adjust the pH to 7.2;

[0027] Step 2: Under stirring, keep the temperature at 40°C, add emulsifier and dibutyl phthalate, keep warm at 40°C for 1 hour and stir, then cool to room te...

Embodiment 3

[0031] White latex adhesive, comprising 380 parts of polyvinyl alcohol, 7 parts of hydrochloric acid, 35 parts of sodium tripolyphosphate, 8.5 parts of liquid caustic soda, 14 parts of emulsifier, 17 parts of dibutyl phthalate, 490 parts of polyvinyl acetate by weight Parts, 280 parts of fillers, 3 parts of triethanolamine oleate.

[0032] Among them, the emulsifier is OP-10 or TX-10; the filler is talcum powder, titanium dioxide or lithopone.

[0033] The preparation method of white latex adhesive of the present invention: comprise the following steps:

[0034] Step 1: Dissolve polyvinyl alcohol in water at 92°C, adjust the pH value to 2-3 with hydrochloric acid, keep the temperature at 92°C, add sodium tripolyphosphate under stirring, react for 1 hour, cool down to below 50°C, Add liquid caustic soda to adjust the pH value to 6.5;

[0035] Step 2: Under stirring, keep the temperature at 45°C, add emulsifier and dibutyl phthalate, keep warm at 45°C for 1h and stir, then coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com