Modified pitch production device

A modified asphalt, production equipment technology, applied in the direction of processing tar pitch/petroleum pitch/natural pitch by distillation, processing tar pitch/petroleum pitch/natural pitch by chemical methods, etc., can solve the problems of large process wastewater, temperature and time Control requirements are high, product quality is difficult to control, etc., to achieve the effect of short process flow, ensure the flexibility of operation, and reduce the possibility of equipment and pipeline coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

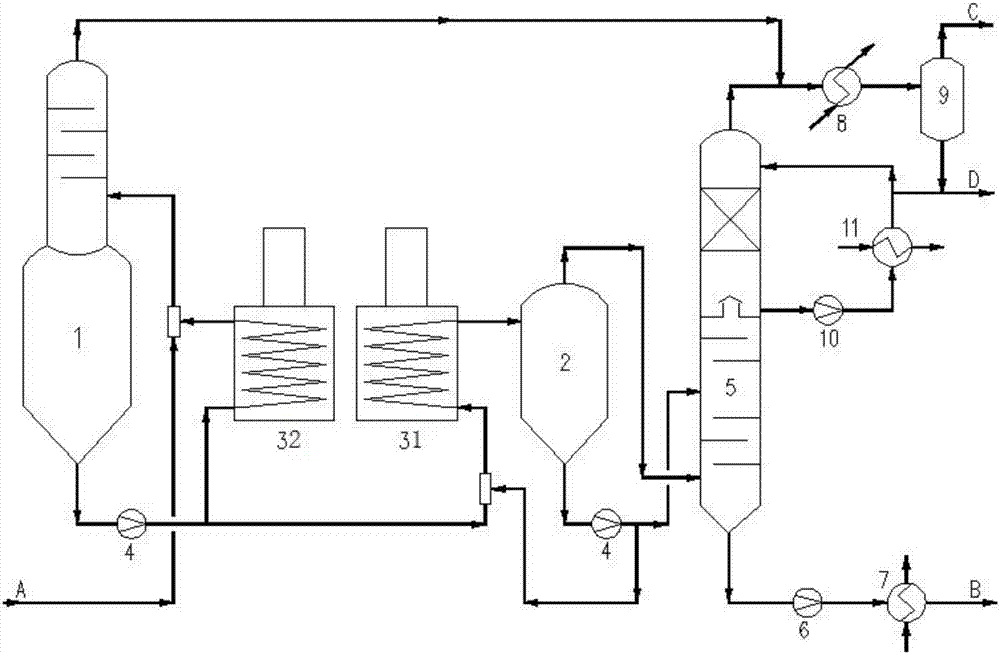

[0028] Such as figure 1 As shown, a modified asphalt production device described in the present invention includes a flash reforming reactor 1, a tubular heating furnace 1, a secondary reforming reactor 2 and a fractionation tower 5; the flash reforming reaction Kettle 1 is composed of a connected upper flash tower and a lower reaction kettle. The asphalt inlet of the flash tower is connected to the raw asphalt delivery pipeline, and the oil and gas extraction outlet at the top of the flash tower is connected to the oil and gas condensation cooler 8; the asphalt at the bottom of the reaction kettle The outlet is connected to the furnace tube inlet of tubular heating furnace 1, and the furnace tube outlet of tubular heating furnace 1 31 is connected to the asphalt inlet on the upper part of the secondary reforming reactor 2; the bottom asphalt outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com