Application of alkane oxygen carrier in increasing yield of polymalic acid of aureobasidium pullulans

A technology of Aureobasidium pullulans and polymalic acid, applied in the field of microorganisms, can solve the problems of poor concentration of pullulan and achieve the effect of inhibiting synthesis and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A. pullulans HA-4D with the preservation number CGMCC No. 7.208 was inoculated into a 500 mL shaker flask containing 100 mL of seed medium, and cultured on a shaking table at a temperature of 25°C and a rotation speed of 200 rpm for 48 hours. Then take 10 mL of the seed solution and inoculate it in a 500 mL shake flask, which contains 90 mL of basic fermentation medium, and additionally add 1 mL of n-heptane, and then culture in a shaker at a temperature of 25 °C and a speed of 200 rpm for 144 hours. The results showed that the yield of polymalic acid in this example was 33.8g / L, and the yield of pullulan was 2.5g / L.

[0032] At the same time, a comparative experiment was carried out according to the same method as above, except that the basic fermentation medium was used and n-heptane was not added. The results showed that the yield of polymalic acid in this comparative example was 30.3 g / L, and the yield of pullulan was 5.9 g / L.

[0033] Compared with Comparative Exa...

Embodiment 2

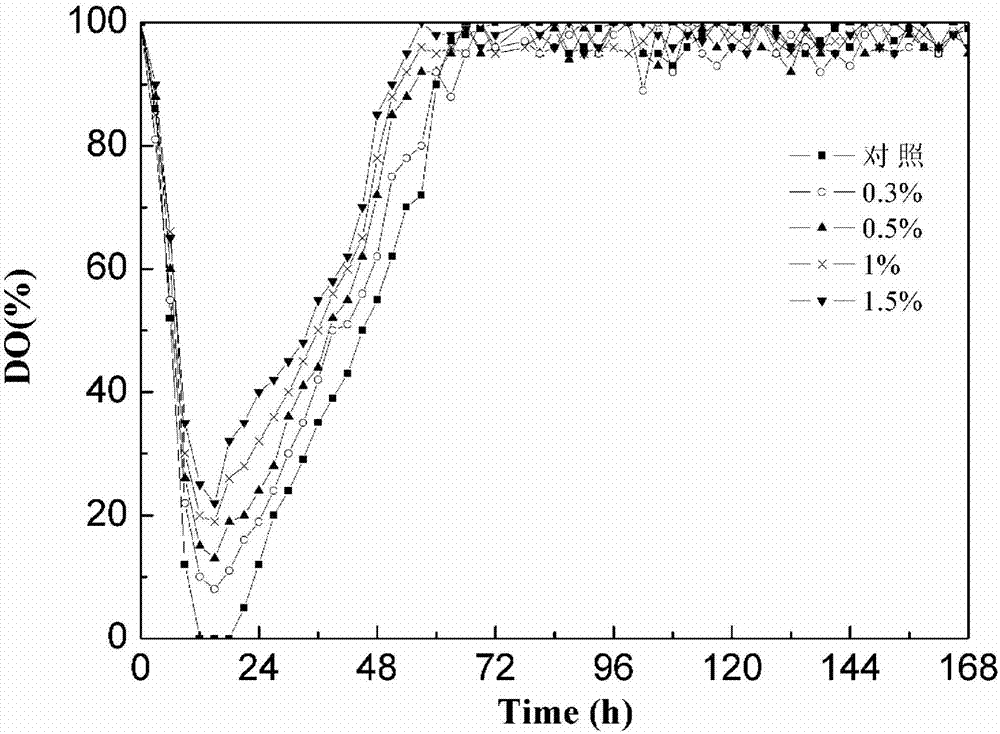

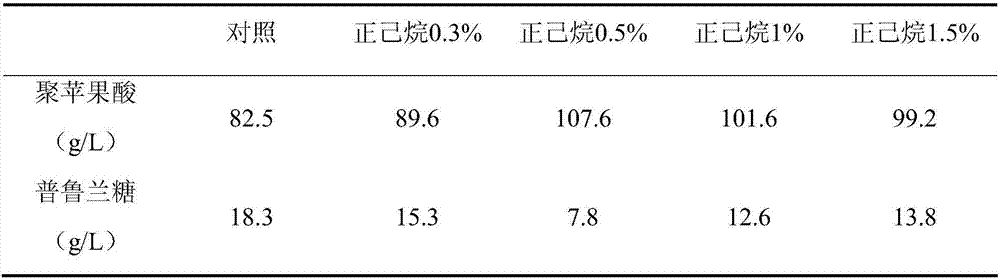

[0035] Aureobasidium pullulans HA-4D with the preservation number CGMCC No.7.208 was inoculated in a 500mL shake flask containing 100mL seed medium, and cultured on a shaking table at a temperature of 25°C and a rotation speed of 200rpm for 48h, and the seed solution was prepared 3 bottles. Then take 300mL of seed solution and inoculate it in a 5L mechanically stirred fermenter. The fermenter is equipped with 2.7L of basic fermentation medium, and an additional 30mL of n-heptane is added. Fermentation was carried out under the conditions, and when the concentration of residual sugar in the fermentation broth was lower than 10g / L, 300g / L glucose was continuously added to the tank at a flow rate of 12mL / h, and the fermentation was terminated after 168 hours. In this example, the yield of polymalic acid was 102.8g / L, and the yield of pullulan was 8.7g / L.

[0036]At the same time, a comparative experiment was carried out according to the same method as above, except that the basi...

Embodiment 3

[0039] A. pullulans HA-4D with the preservation number CGMCC No. 7.208 was inoculated into a 500 mL shaker flask containing 100 mL of seed medium, and cultured on a shaking table at a temperature of 25°C and a rotation speed of 200 rpm for 48 hours. Then take 10 mL of the seed solution and inoculate it in a 500 mL shake flask, which contains 90 mL of basic fermentation medium, and additionally add 1 mL of n-dodecane, and then culture in a shaker at a temperature of 25°C and a speed of 200 rpm for 144 hours. The results showed that the yield of polymalic acid in this example was 32.9g / L, and the yield of pullulan was 2.7g / L.

[0040] At the same time, a comparative experiment was carried out according to the same method as above, except that the basic fermentation medium was used and n-dodecane was not added. The results showed that the yield of polymalic acid in this comparative example was 30.3 g / L, and the yield of pullulan was 5.9 g / L.

[0041] Compared with Comparative Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com