Surface-modified porous metal implant and preparation method thereof

A porous metal and surface modification technology, applied in the field of medical devices, can solve problems such as uneven thickness of micro-arc oxidation coating, achieve the effect of reducing the gap in electric field strength and optimizing electric parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

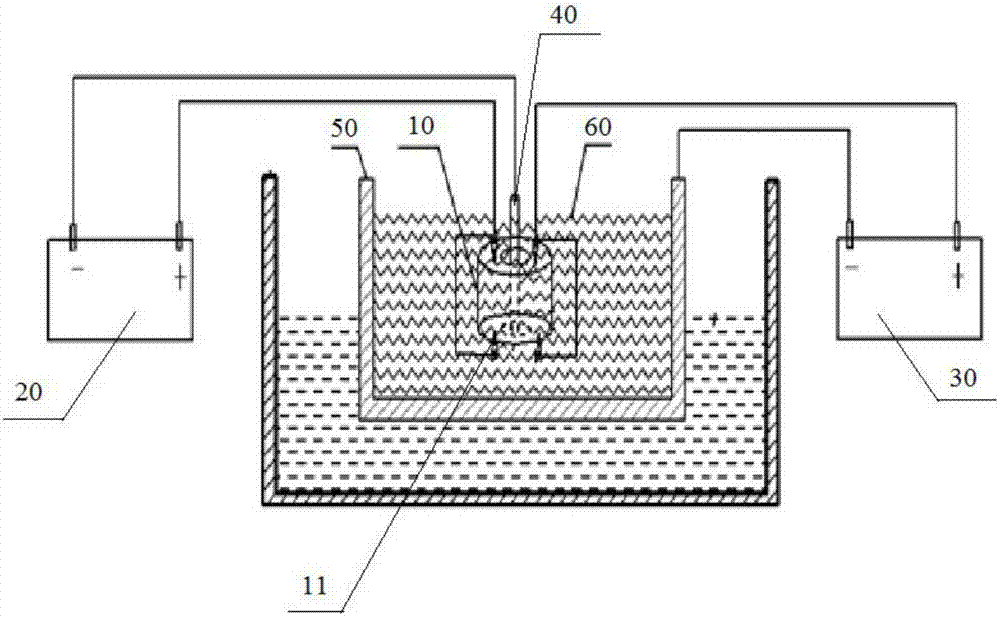

[0038] In a typical embodiment of the present application, a method for preparing a surface-modified porous metal implant is provided, the porous metal implant has structural pores, the preparation method includes performing micro-arc oxidation with multiple power supplies In the step, the plurality of power sources includes a first power source and a second power source, and the above step of micro-arc oxidation includes: connecting the first positive electrode interface of the porous metal implant to the positive electrode of the first power source; setting the connection negative electrode in the structural hole, And connect the negative pole to the negative pole of the first power supply; The second positive pole interface of the porous metal implant is connected to the positive pole of the second power supply; The electrolytic tank is connected to the negative pole of the second power supply; The porous metal implant is immersed in the The electrolytic solution is powered ...

Embodiment 1

[0067] The porous metal implant 10 prepared by electron beam melting technology is used as the modified object of embodiment 1. The porous metal implant has a central hole. When the inscribed circle of the central hole is directly 4mm, the diameter of the circumscribed circle is 10mm, and the height It is a cylindrical microporous titanium alloy with a diameter of 5mm, the porosity of the micropores is 60%, and the pore diameter is 400 μm. Four positive electrode interfaces 11 are arranged on the upper and lower end surfaces of the porous metal implant, and two of them are arranged at equal intervals on the upper end surface. Positive electrode interface 11, two positive electrode interfaces 11 are arranged at equal intervals on the lower end surface, and all four positive electrode interfaces are equidistant from the axis of the central hole.

[0068] The porous metal implant was subjected to strong sand blasting, the abrasive was corundum sand with a powder particle size of 5...

Embodiment 2

[0073] The difference from Example 1 is that the power supply voltage of the first power supply is adjusted to 200V, the power supply voltage of the second power supply is 700V, the output pulse frequency is 1200Hz, the pulse width is 400μs, the peak current is set to 160A, and the oxidation time is 10min.

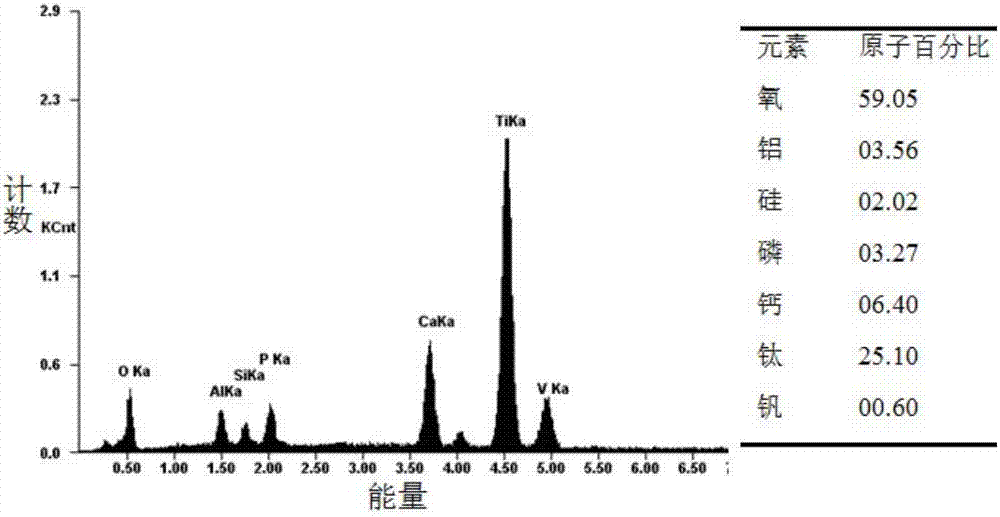

[0074] figure 2 It is an EDS energy spectrum analysis diagram of the in-situ growth film layer formed according to Example 2 of the present invention. The results show that the film layer contains calcium, phosphorus and other biologically active elements, which is beneficial to improve the biological activity of the porous metal implant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com