Cooling device of polycrystalline ingot furnace for supersized silicon ingot

A super-sized cooling device technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of long crystal growth time and affecting the crystal growth effect, and achieve faster cooling speed, enhanced protection, and cooling capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

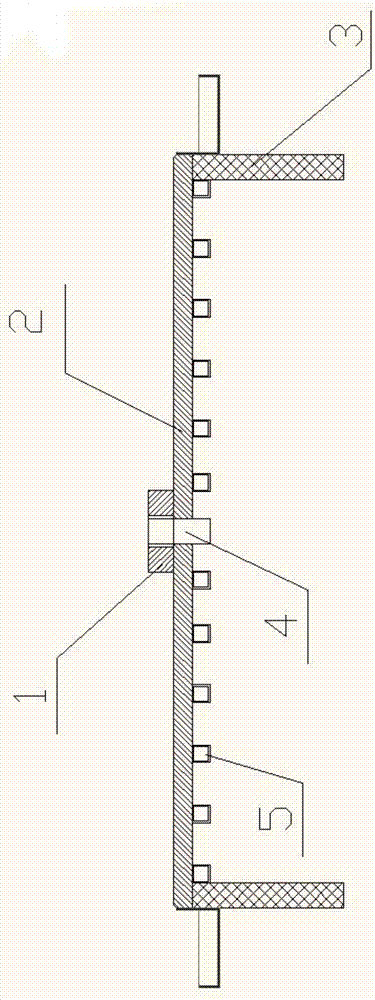

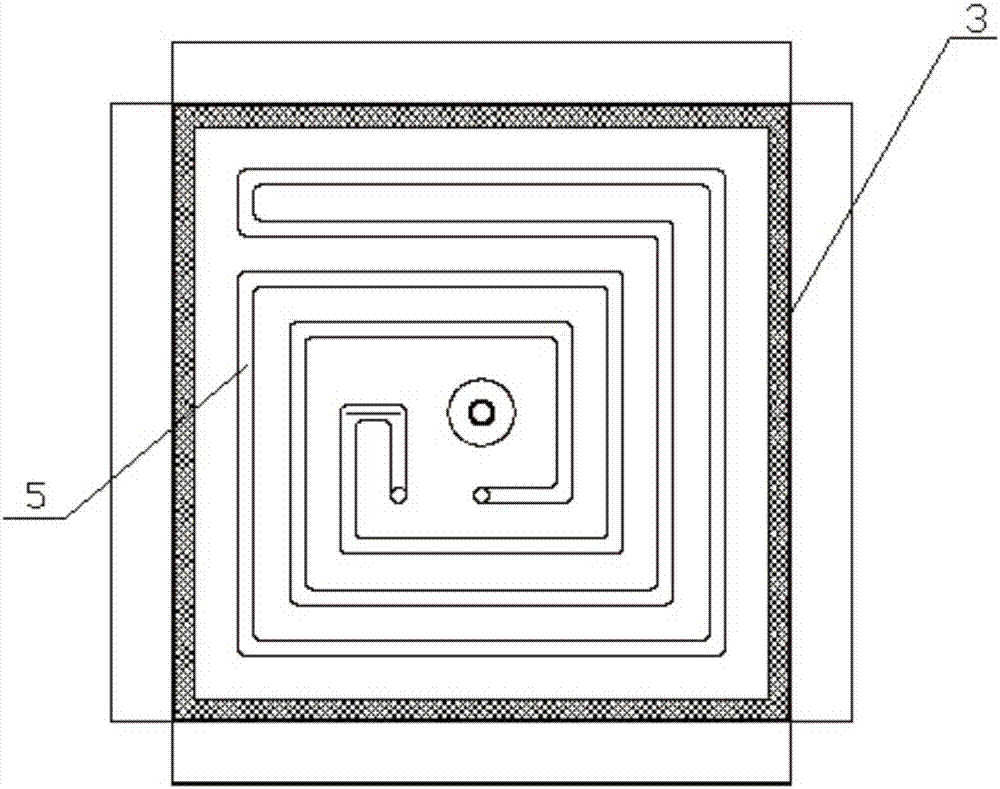

[0017] refer to figure 1 and figure 2 A cooling device for a polycrystalline ingot furnace for super-sized silicon ingots, comprising a cooling heat dissipation plate 2 arranged in the lower furnace body of the polycrystalline ingot furnace, the cooling heat radiation plate 2 is fixed in the lower furnace body through a support frame, The cooling heat dissipation plate 2 is a molybdenum plate or a copper plate, the shape is a square, and its thickness is 30mm. A temperature measuring sampling hole is provided at the center of the cooling radiating plate 2, and the lower surface of the cooling radiating plate 2 is covered with cooling pipes 5. One import and one export. The cooling pipe 5 is made of a metal material with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com