Method for operating low-speed marine engine in variable thermodynamic cycle mode

A thermodynamic cycle and engine technology, which is applied in engine control, combustion engine, machine/engine, etc., can solve the problems that high-pressure gas engines cannot achieve homogeneous lean combustion, so as to ensure reliability and economy, reduce emission values, and realize The effect of homogeneous low temperature combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

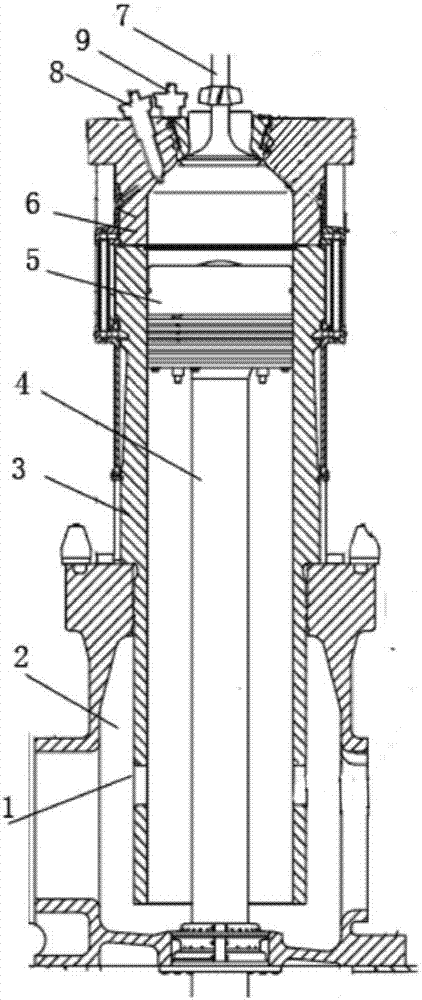

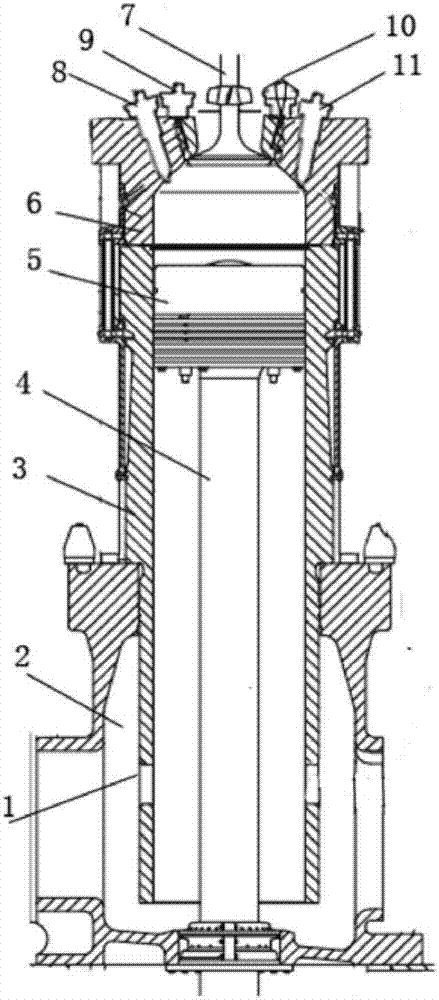

[0027] The invention provides a method for operating a marine engine in a variable thermodynamic cycle mode, which realizes two or more thermodynamic cycles based on an engine electronic injection control system. While keeping the original design of the Diesel cycle mode of the high-pressure gas engine unchanged, the Otto cycle mode is added. And it can realize low-temperature homogeneous lean combustion and reduce emissions through technology combination, so that the engine has the advantages of high and low pressure gas engines at the same time. Specifically:

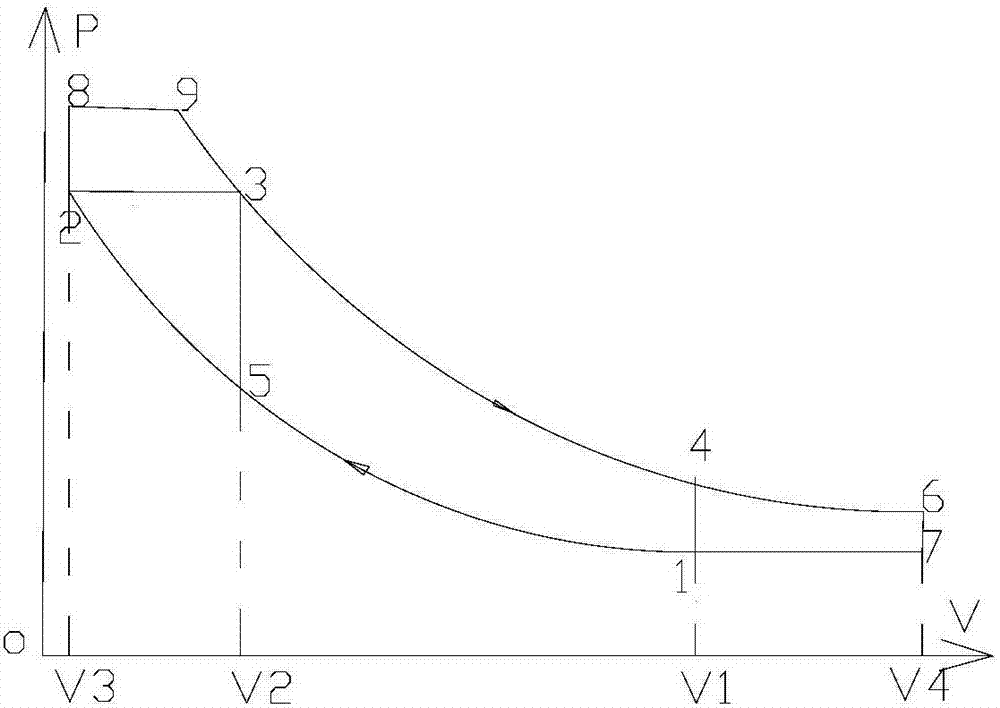

[0028] Such as figure 1 As shown, when the ship is sailing outside the emission control area, the engine can be used in Diesel ( figure 1 , 1-2-3-4) or cycle (1-2-3-4-6-7) to work, to achieve diffusion combustion, with high thermal efficiency, high power density, and good dynamic performance.

[0029] When the ship is navigating in the emission control area, the engine is in Otto ( figure 1 , 1-5-3-4) or cycle (1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com