Liquid level sensor system based on monomode -multimode-monomode optical fiber structure and Bragg gratings

A fiber optic Bragg and liquid level sensor technology, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, liquid level indicators, etc., can solve the problem that the cladding mode reflection spectrum is not easy to obtain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

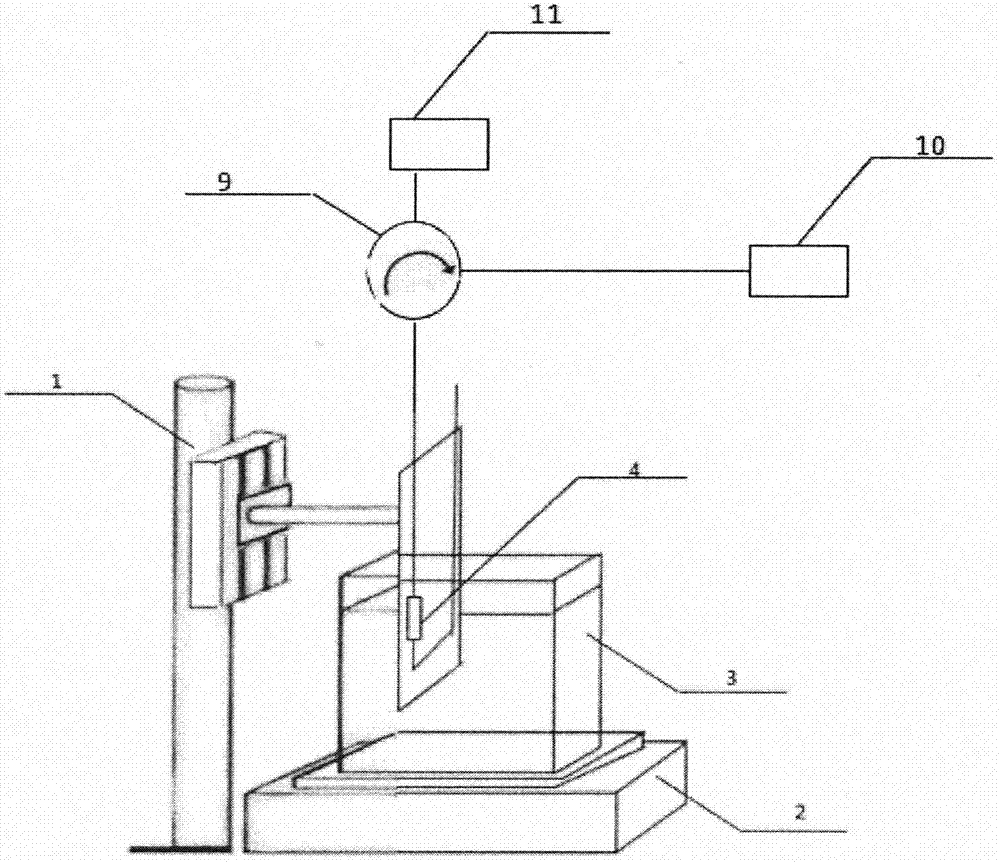

[0014] figure 1 In the present invention, a liquid level sensor system based on a single-mode-multimode-single-mode optical fiber structure and a Bragg grating includes an electric linear table 1, a temperature control table 2, a water container 3, and an optical fiber group 4. The optical fiber group 4 Immerse in the water container 3, and connect the electric linear table 1 with the optical fiber group 4 through the support at the same time, the water container 3 is placed on the temperature control table 2, the described optical fiber group 4 is connected with the circulator 9, the circulator 9 is connected with the spectrometer 10 and The broadband light sources 11 are connected in a clockwise direction.

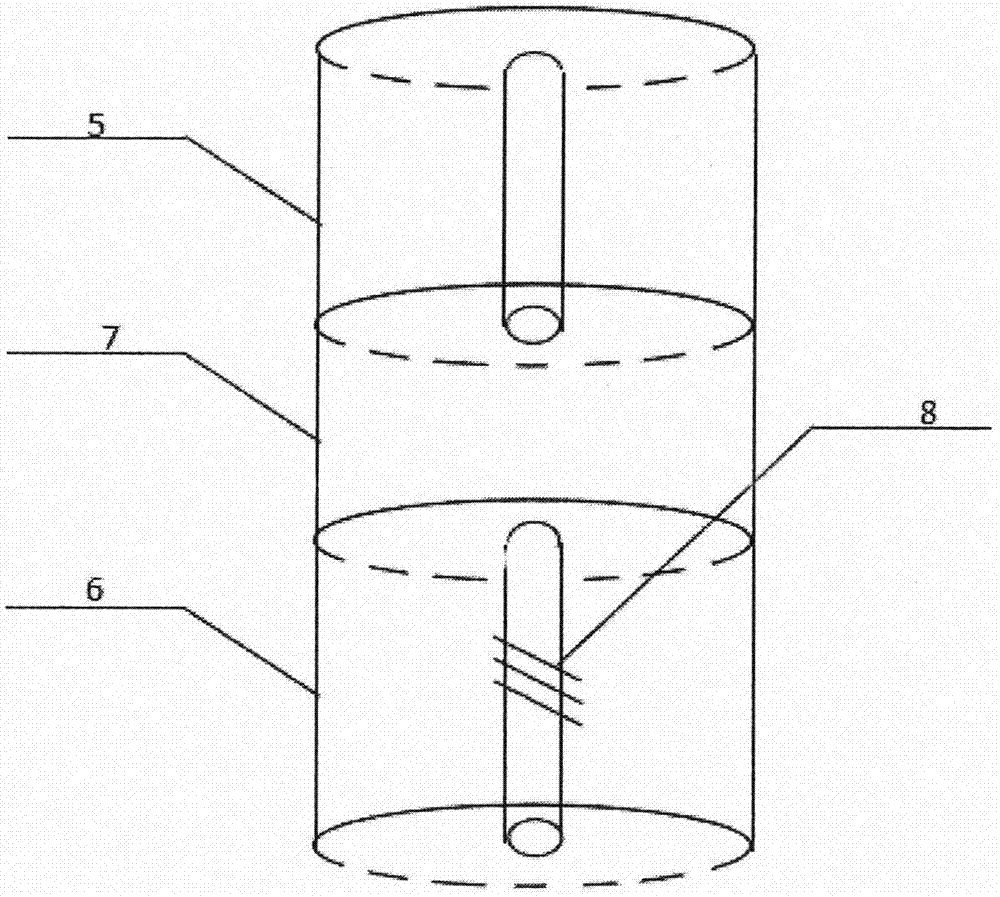

[0015] figure 2 In the present invention, a liquid level sensor system based on a single-mode-multimode-single-mode optical fiber structure and a Bragg grating, the optical fiber group 4 structure consists of a first single-mode optical fiber 5, a second single-mode op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com