Intelligent dry-type transformer and production process thereof

A dry-type transformer and production process technology, which is applied in the direction of transformer/inductor cooling, transformer/inductor parts, inductor/transformer/magnet manufacturing, etc., can solve the problems of high noise and high energy consumption, and achieve low energy loss, Good mechanical strength and strong lightning impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

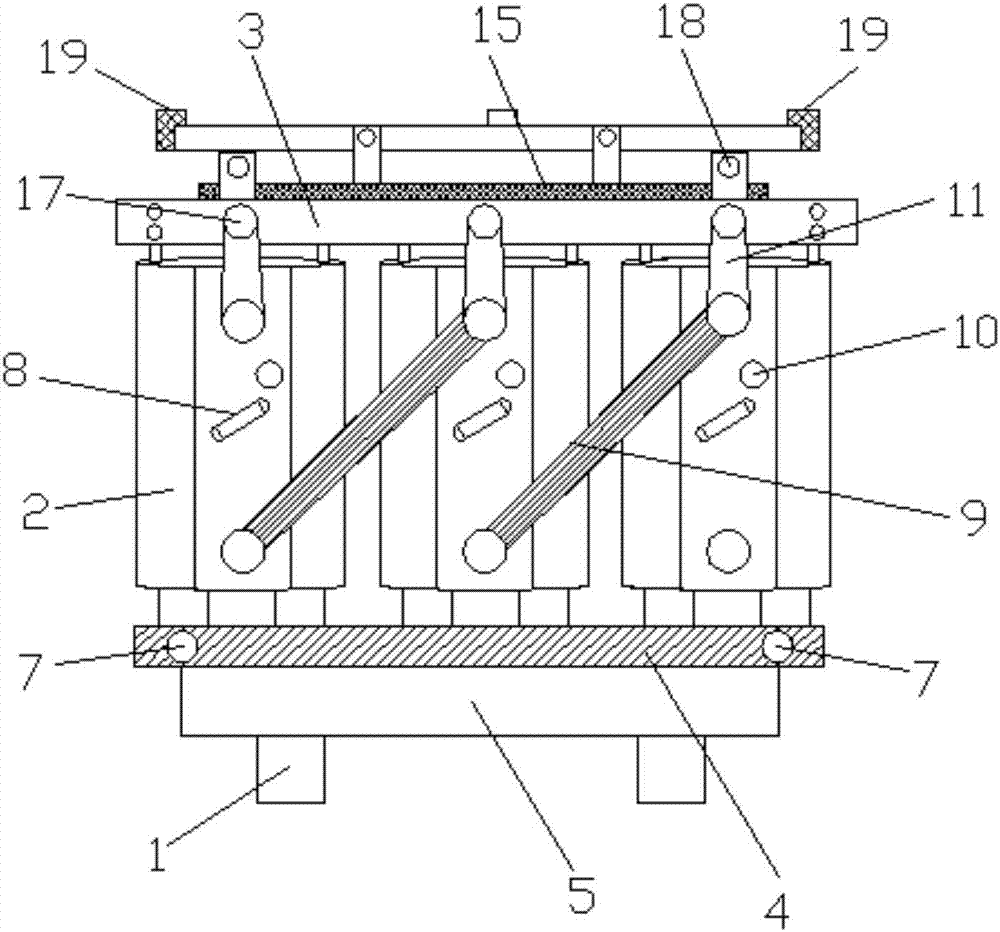

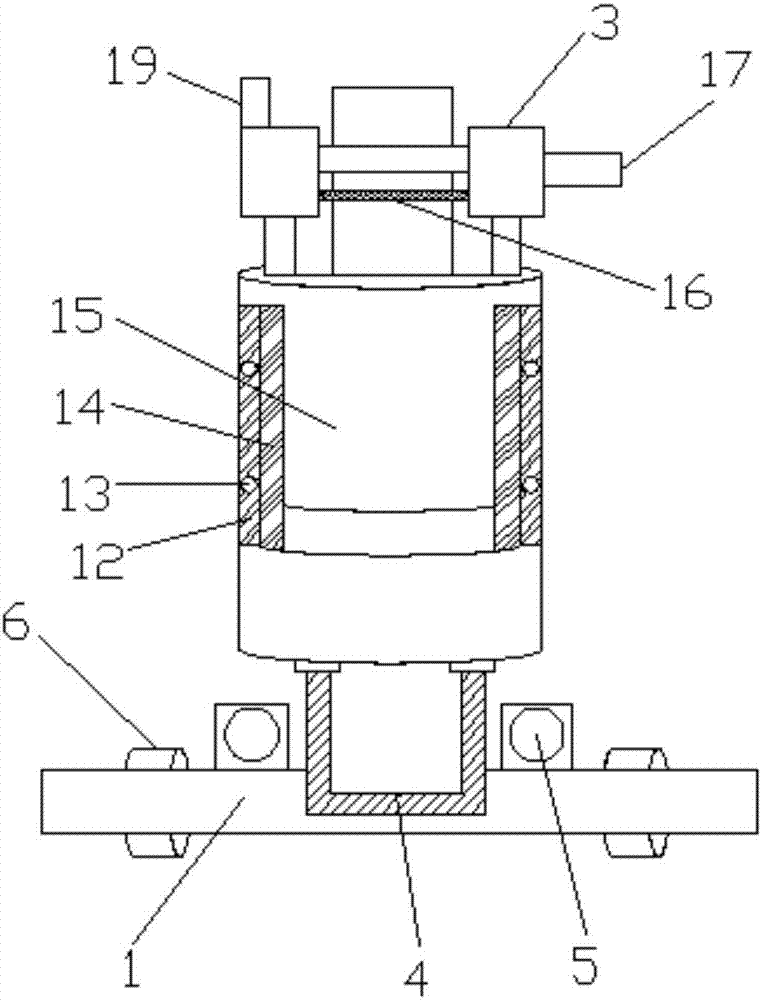

[0024] see Figure 1-2 , the present invention provides a technical solution: an intelligent dry-type transformer, including a base 1, a transformer 2 and an upper frame 3, the base 1 is provided with a pad 4, a fan 5, a two-way wheel 6 and a grounding screw 7, the The transformer 2 is fixedly connected to the pad 4, and the side of the transformer 2 is provided with a high-voltage connecting piece 8, a high-voltage connecting rod 9, a high-voltage tap 10 and a high-voltage connecting pipe 11. The inside of the transformer 2 includes a cooling air passage 12, a high-voltage line coil 13, low-voltage coil 14 and iron core 15, the upper end of the transformer 2 is fixedly connected to the upper frame 3, and the upper frame 3 is provided with a clip 16, a high-voltage terminal 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com