35kv integrated photovoltaic combined transformer for photovoltaic power generation system

A photovoltaic power generation system and combined transformer technology, applied in the field of transformers, can solve problems such as difficult commissioning and maintenance, large space occupation, and accident-prone problems, and achieve the effects of unified commissioning and maintenance, small footprint, and perfect protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

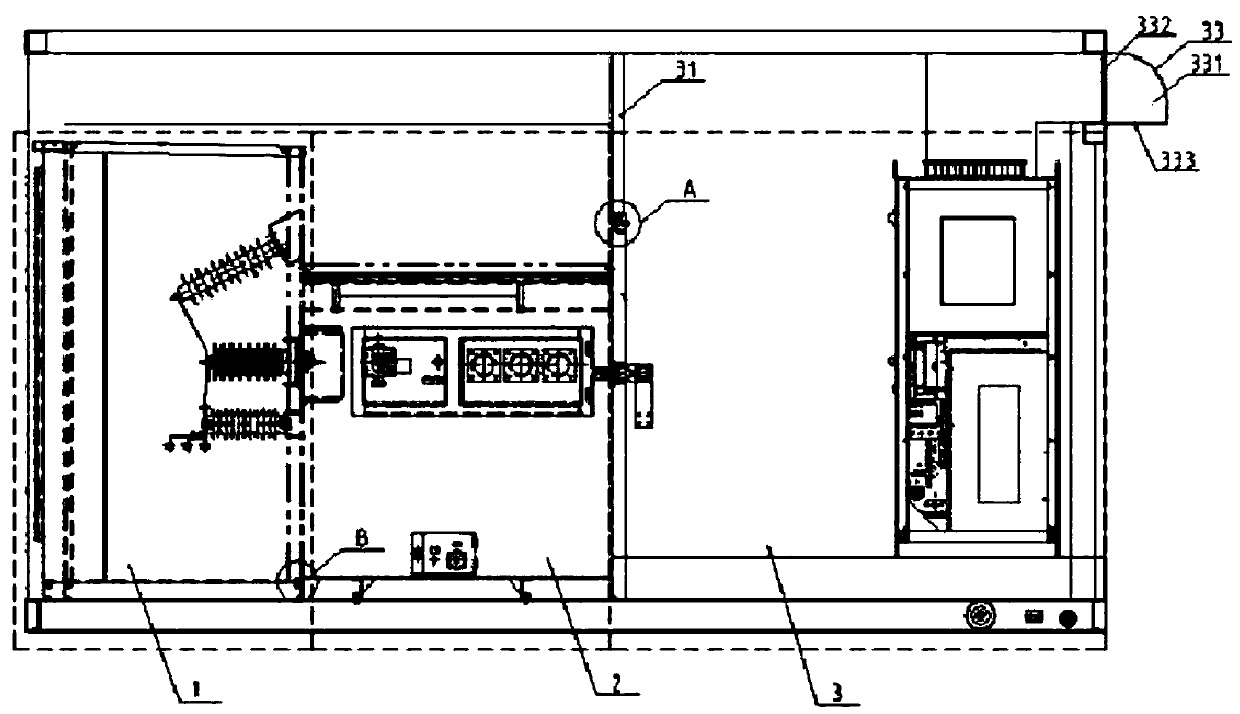

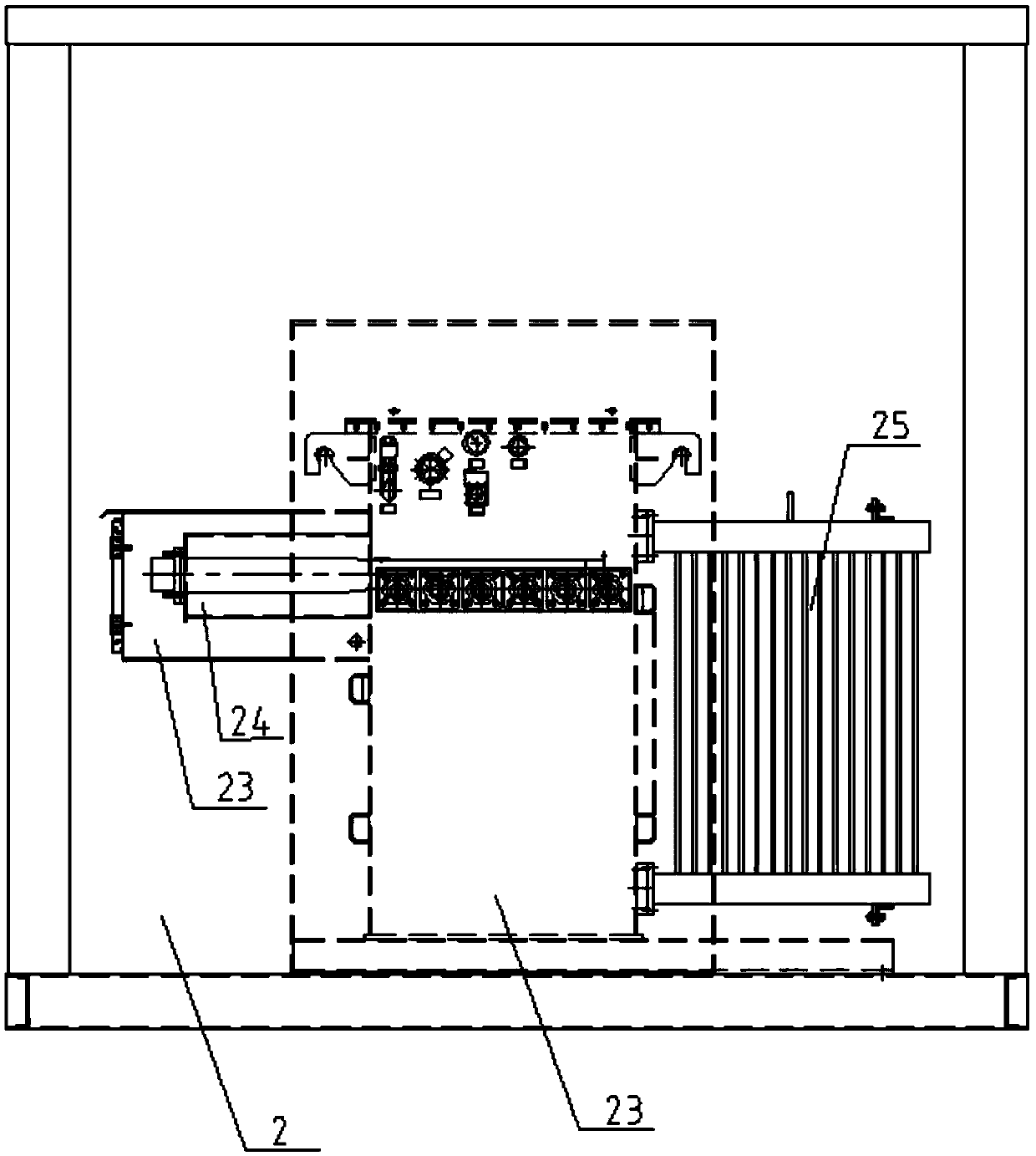

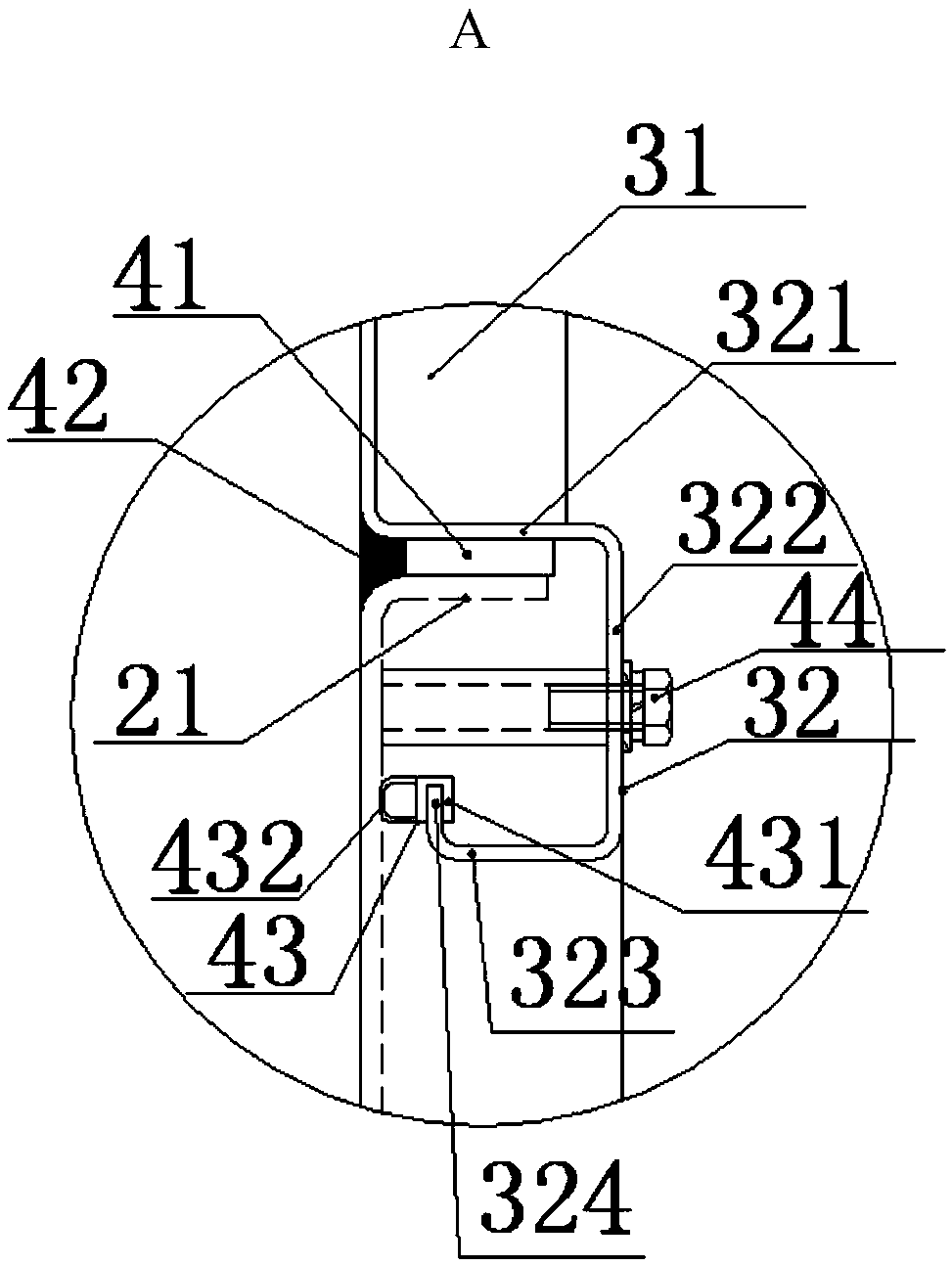

[0024] 35kV integrated photovoltaic combined transformer for photovoltaic power generation system, such as Figure 1-4 , including high voltage chamber 1, transformer chamber 2, and inverter chamber 3 from left to right; the side wall of inverter chamber 3 at the contact point with transformer chamber 2 is the side wall 31 with a gap in the middle, and the side wall of transformer chamber 2 Snap to the side wall 31 with a gap in the middle, the end of the side wall 31 with a gap in the middle is a U-shaped flange 32, the end of the wall of the transformer room 2 is provided with a transverse flange 21, and the side wall with a gap in the middle 31 and the side wall of the transformer chamber 2 are connected by U-shaped fold 32 and transverse fold 21; Vertical side 324, a sealing strip 41 and silicone glue 42 are provided between the first transverse side 321 and the transverse folded side 21, and a strip steel sealing strip 43 is provided between the second vertical side 324 a...

Embodiment 2

[0026] 35kV integrated photovoltaic combined transformer for photovoltaic power generation system, such as Figure 1-4 , including high voltage chamber 1, transformer chamber 2, and inverter chamber 3 from left to right; the side wall of the inverter chamber 3 in contact with the transformer chamber 2 is the side wall 31 with a gap in the middle, and the side wall of the transformer chamber 2 Snap to the side wall 31 with a gap in the middle, the end of the side wall 31 with a gap in the middle is a U-shaped flange 32, the end of the wall of the transformer room 2 is provided with a transverse flange 21, and the side wall with a gap in the middle 31 and the side wall of the transformer chamber 2 are connected by U-shaped fold 32 and transverse fold 21; Vertical side 324, a sealing strip 41 and silicone glue 42 are provided between the first transverse side 321 and the transverse folded side 21, and a strip steel sealing strip 43 is provided between the second vertical side 324...

Embodiment 3

[0029] 35kV integrated photovoltaic combined transformer for photovoltaic power generation system, such as Figure 1-4 , including high voltage chamber 1, transformer chamber 2, and inverter chamber 3 from left to right; the side wall of inverter chamber 3 at the contact point with transformer chamber 2 is the side wall 31 with a gap in the middle, and the side wall of transformer chamber 2 Snap to the side wall 31 with a gap in the middle, the end of the side wall 31 with a gap in the middle is a U-shaped flange 32, the end of the wall of the transformer room 2 is provided with a transverse flange 21, and the side wall with a gap in the middle 31 and the side wall of the transformer chamber 2 are connected by U-shaped fold 32 and transverse fold 21; Vertical side 324, a sealing strip 41 and silicone glue 42 are provided between the first transverse side 321 and the transverse folded side 21, and a strip steel sealing strip 43 is provided between the second vertical side 324 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com