Colored polyurethane foam sealant as well as preparation method and application thereof

A technology of polyurethane foam and caulking agent, which is applied in the field of urethane foam caulking agent, can solve the problems of dull and unnatural color, unbeautiful landscaping, increased use cost, etc., and achieves strong plasticity, safe and convenient use, and reduced stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

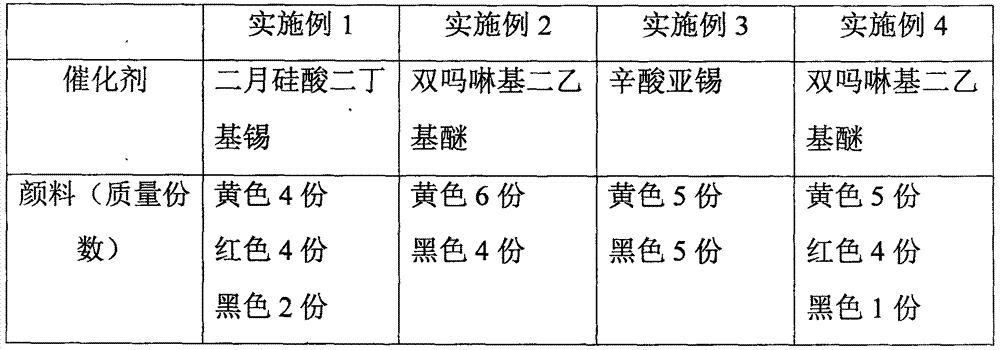

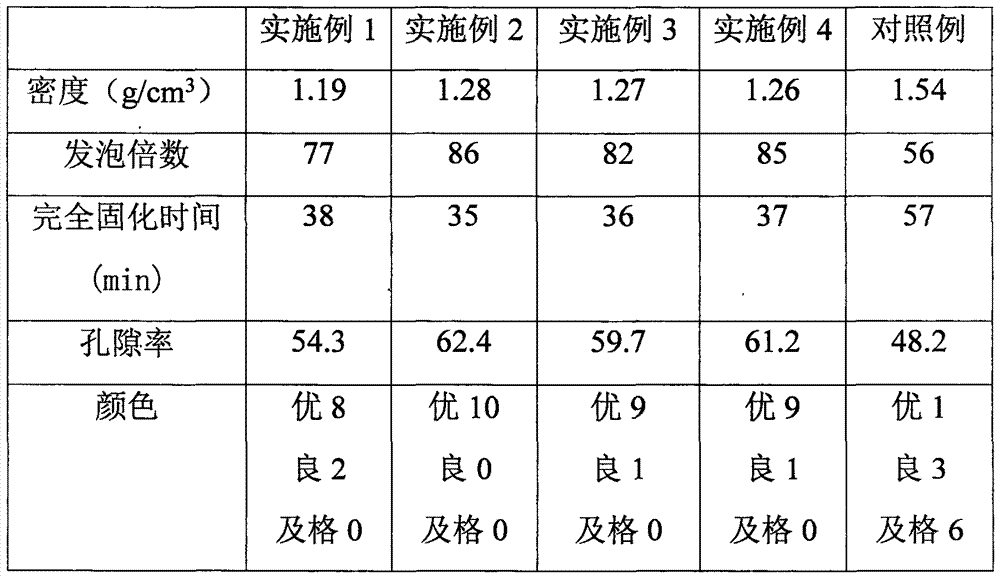

[0023] The technical solutions of the present invention will be further disclosed below in conjunction with specific embodiments.

[0024] A polyurethane foam caulking agent with color, its components include paraffin wax, polyether polyol, polymethylene polyphenyl isocyanate (MDI), stabilizer, catalyst, solvent and pigment according to mass fraction. The pigments are YE-3659, RE-3645 and BL-3544 produced by Qingdao Baozhi Plastic Material Co., Ltd. or yellow 1#, red 9# and black 21# produced by Jinan Xinxing Chemical Co., Ltd. The paraffin is a mixture of chlorinated paraffin 42# and chlorinated paraffin 52#, and the ratio by weight is chlorinated paraffin 42#:chlorinated paraffin 52#=16~30:10~20. The polyether polyol is a polyether polyol with a hydroxyl value of 180-260 mgKOH / g and a functionality of 2-3. The stabilizer is silicone oil, the solvent is propane, and the catalyst is at least one of dimorpholino diethyl ether (DEDEE), stannous octoate, and dibutyltin dilaurate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com