Detection method for real-time continuous monitoring of release of volatile organic compounds in plastic runway and application of detection method

A technology of organic compounds and plastic track, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of failure to monitor, suffocation, and inability to simulate the use environment of plastic track, so as to achieve accurate and true test results and easy experimental operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

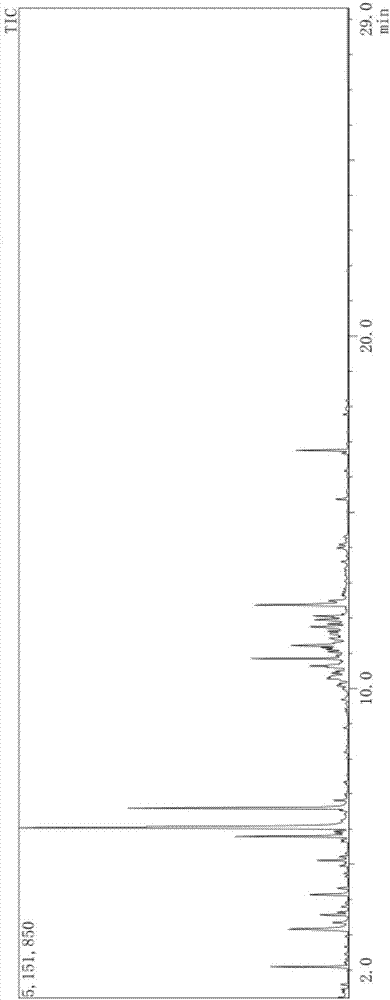

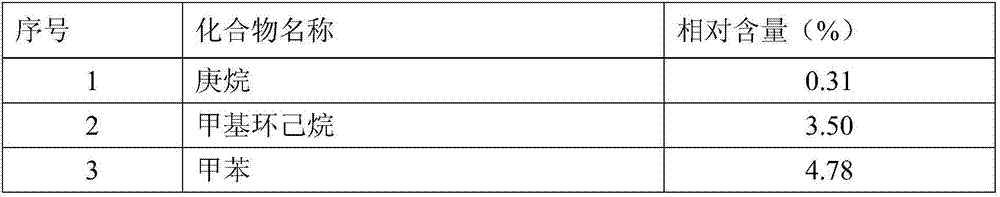

[0035] (1) Place a complete plastic runway sample in a 15L small experimental cabin, set the temperature of the experimental cabin to 25°C, humidity to 40%, air velocity to 0.1m / s, and air replacement rate to 1.0h -1 .

[0036] (2) After the sample is left for 24 hours, collect the air in the box with a constant flow sampler at a flow rate of 0.5mL / min, and let the extracted air pass through the pre-activated Tenax TA adsorption tube, and the sample collection time is 30 minutes.

[0037] (3) Fix the Tenax TA adsorption tube on the secondary thermal desorption instrument, after thermal desorption, the volatile organic compounds enter the gas chromatography-mass spectrometry instrument for detection, perform qualitative analysis by searching the spectral library and normalize according to the area semi-quantitative analysis.

[0038]The purging time of the secondary thermal analyzer is 5 minutes, the desorption time is 1 minute, the desorption temperature is 250°C, the pipelin...

Embodiment 2

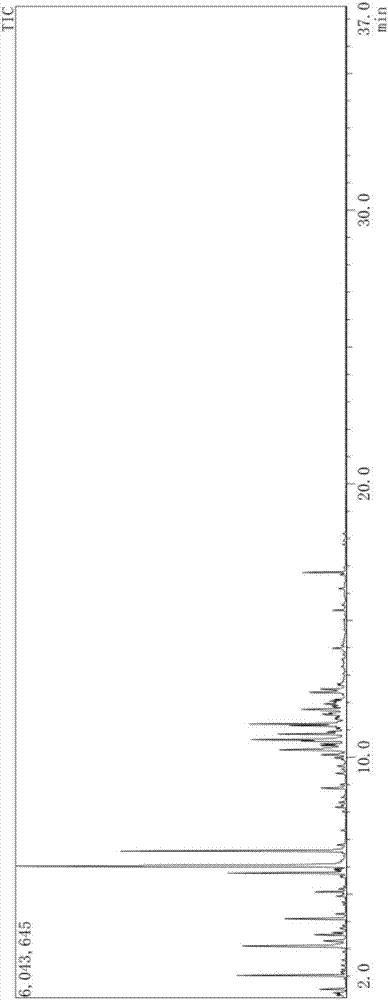

[0044] (1) Place a complete plastic runway sample in a 15L small experimental cabin, set the temperature of the experimental cabin to 50°C, humidity to 45%, air velocity to 0.5m / s, and air replacement rate to 1.0h -1 .

[0045] (2) After the sample is placed for 48 hours, collect the air in the box with a constant flow sampler at a flow rate of 0.5mL / min, and let the extracted air pass through the pre-activated Tenax TA adsorption tube, and the sample collection time is 40 minutes.

[0046] (3) Fix the Tenax TA adsorption tube on the secondary thermal desorption instrument, after thermal desorption, the volatile organic compounds enter the gas chromatography-mass spectrometry instrument for detection, perform qualitative analysis by searching the spectral library and normalize according to the area semi-quantitative analysis.

[0047] The purging time of the secondary thermal analyzer is 8 minutes, the desorption time is 2 minutes, the desorption temperature is 300°C, the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com