Pressure energy recycle device for high-pressure hydrogen storage tank of hydrogen fuel cell automobile

A fuel cell and recycling device technology, which is applied to fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as pressure waste and energy waste, and achieve the effect of saving energy consumption and facilitating safe driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

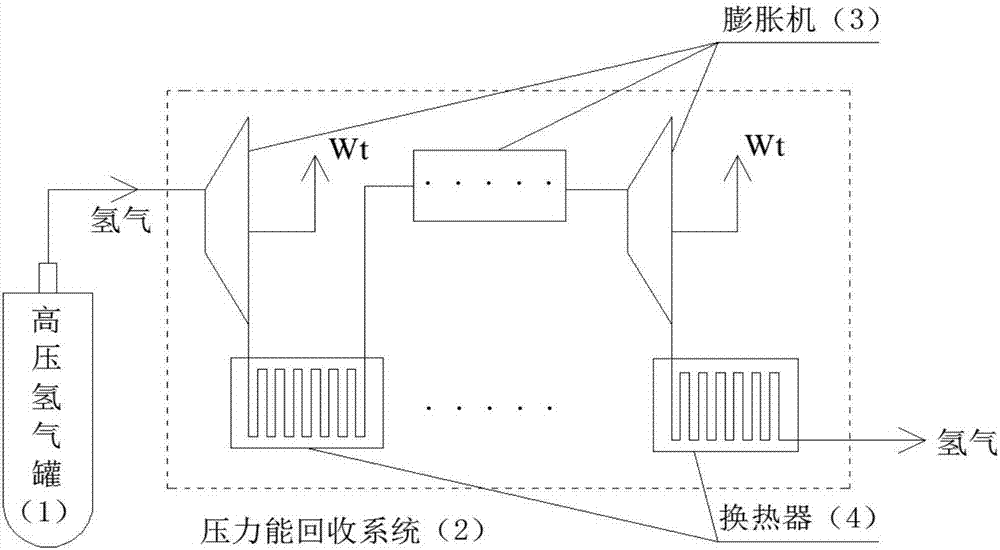

[0021] Such as Figure 5 As shown, a high-pressure hydrogen storage tank pressure energy recovery device for a hydrogen energy vehicle includes: a high-pressure hydrogen tank (1), a pressure energy recovery system (2), and the pressure energy recovery system (2) includes an expander (3) And heat exchanger (4), compressor (5). This case adopts a two-stage expansion system. The high-pressure hydrogen flows out from the high-pressure hydrogen tank (1) and flows into the expansion systems at all levels in sequence; work, and then flow into the primary water-cooled heat exchanger (4) to absorb the heat of fuel cell cooling water to achieve temperature rise; then flow into the secondary piston expander (3) to continue to expand and reduce pressure to do external work, and then flow into the secondary air-cooled Heat exchanger (4) absorbs air heat.

[0022] Such as Figure 5 As shown, using the two-stage expansion system, this part of the work can drive the air compressor (5) to r...

Embodiment example 2

[0024] Such as Figure 6 As shown, a high-pressure hydrogen storage tank pressure energy recovery device for a hydrogen energy vehicle includes: a high-pressure hydrogen tank (1), a pressure energy recovery system (2), and the pressure energy recovery system (2) includes an expander (3) And heat exchanger (4), transmission mechanism (6). This case adopts a three-stage expansion system, and the high-pressure hydrogen flows out from the high-pressure hydrogen tank (1) and flows into the expansion system at all stages in sequence. In the first-stage expansion system, the hydrogen flows into the first-stage scroll expander (3) to lower the temperature and pressure, output power to the outside, and then flows into the first-stage air-cooled heat exchanger (4) to absorb heat to achieve temperature rise; then flows into the second-stage The first-stage scroll expander (3) expands and reduces pressure, does external work, and flows into the second-stage air-cooled heat exchanger (4) ...

Embodiment example 3

[0027] Such as Figure 7 As shown, a high-pressure hydrogen storage tank pressure energy recovery device for a hydrogen energy vehicle includes: a high-pressure hydrogen tank (1), a pressure energy recovery system (2), and the pressure energy recovery system (2) includes an expander (3) And heat exchanger (4), generator (7), accumulator (8). In this case, one-stage expansion is adopted. High-pressure hydrogen flows out of the high-pressure hydrogen tank (1), and then passes through the radial axial flow expander (3) to cool down and reduce pressure, output power to the outside, and then flows into the water-cooled heat exchanger (4) to absorb the cooling cycle. The heat of the water is used to achieve temperature rise, and the waste heat of the fuel cell is rationally used.

[0028] Such as Figure 7 As shown, the first-stage expansion is used to do external work, and this part of the expansion work drives the generator (7) to output electric work to complete the charging of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com