Combined emulsifier, aluminum hot rolling oil comprising same and application

A rolling oil and emulsifier technology, applied in the field of combined emulsifier, aluminum hot rolling rolling oil, can solve the problem of sticking to the rolling mill, pipeline and emulsion tank wall, or depositing on the bottom of the emulsion tank, affecting the lubrication condition of the rolling piece Surface quality, aluminum powder is not easy to remove, etc., to achieve the effect of excellent aluminum powder dispersing ability, excellent anti-miscellaneous oil ability, and stable lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

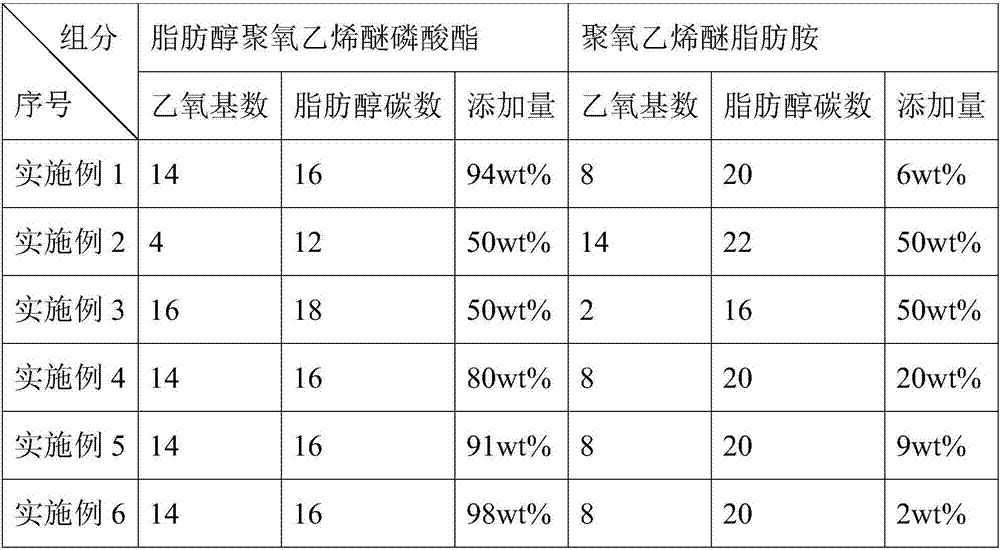

[0064] Combination emulsifiers for aluminum hot rolling rolling oil are provided, the composition is shown in Table 1:

[0065] The formula composition of the combined emulsifier for aluminum hot rolling rolling oil provided by Examples 1 to 6 in Table 1

[0066]

[0067] In Table 1, the number of ethoxy groups refers to the average value of the number of ethoxy groups in the corresponding compounds, and the carbon number of fatty alcohols refers to the average value of the carbon numbers of fatty alcohols in the corresponding compounds.

Embodiment 7~12

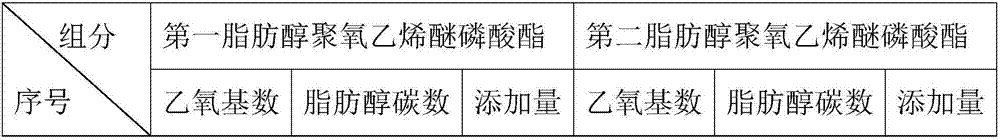

[0069] Provides a combined emulsifier for aluminum hot rolling rolling oil, added with 91 wt% of fatty alcohol polyoxyethylene ether phosphate and 9 wt% of polyoxyethylene ether fatty amine, the polyoxyethylene ether fatty amine having an ethoxy number is 8, the carbon number of the fatty alcohol is 20, the fatty alcohol polyoxyethylene ether phosphate includes the first fatty alcohol polyoxyethylene ether phosphate and the second fatty alcohol polyoxyethylene ether phosphate, the first fatty alcohol polyoxyethylene The specific selection of ethoxy group number and carbon number of oxyethylene ether phosphate and the second fatty alcohol polyoxyethylene ether phosphate is shown in Table 2:

[0070]Selection of fatty alcohol polyoxyethylene ether phosphates of combined emulsifiers provided in Table 2 Examples 7-12

[0071]

[0072]

[0073] In Table 2, the number of ethoxy groups refers to the average value of the number of ethoxy groups in the corresponding compounds, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com