Product observation and measurement method based on five cameras

An observation and measurement, five-camera technology, applied in the field of product observation and measurement based on five cameras, can solve the problems of pasting chip inspection, inability to fully understand and eliminate product quality abnormalities, low production efficiency, etc., to achieve convenient use and efficient observation. , to avoid the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

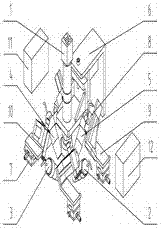

[0015] Such as figure 1 shows a product observation and measurement method based on five cameras, which includes a top camera 1, a right camera 2, a front camera 3, a left camera 4, a rear camera 5, a top camera adjustment frame 6, an XY slide table 7, and a Z axis 8. Camera fixing plate 9, camera fixing frame 10, main control computer 11, sub-controlling computer 12, described XY slide table 7, Z axis 8, camera fixing plate 9, camera fixing frame 10 are 4 pieces, described The top camera 1, the right camera 2, the front camera 3, the left camera 4, and the rear camera 5 have their own independently adjustable optical systems.

[0016] Working process of the present invention is as follows:

[0017] Adjustments when using this method for the first time and when changing products:

[0018] Turn on the main control computer 11, put the product directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com