Catalyst for efficiently catalyzing cycloaddition reaction of carbon dioxide and epoxide

A technology of carbon dioxide and epoxides, applied in the direction of organic compound/hydride/coordination complex catalysts, catalytic reactions, physical/chemical process catalysts, etc., to achieve high-efficiency catalytic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

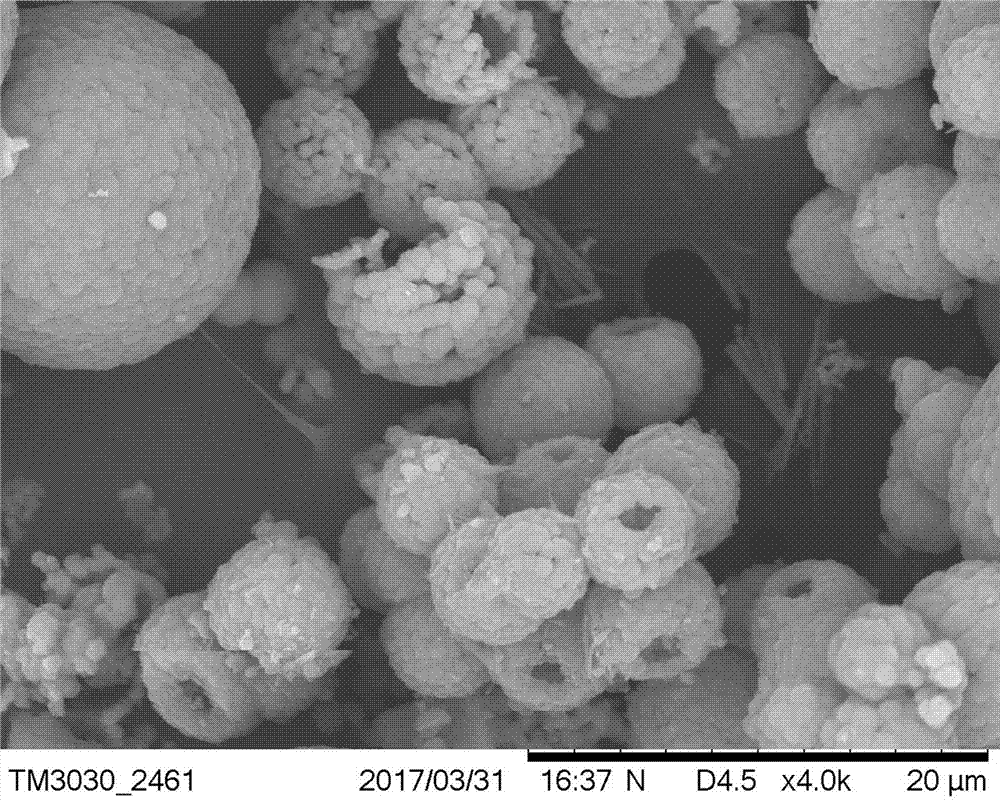

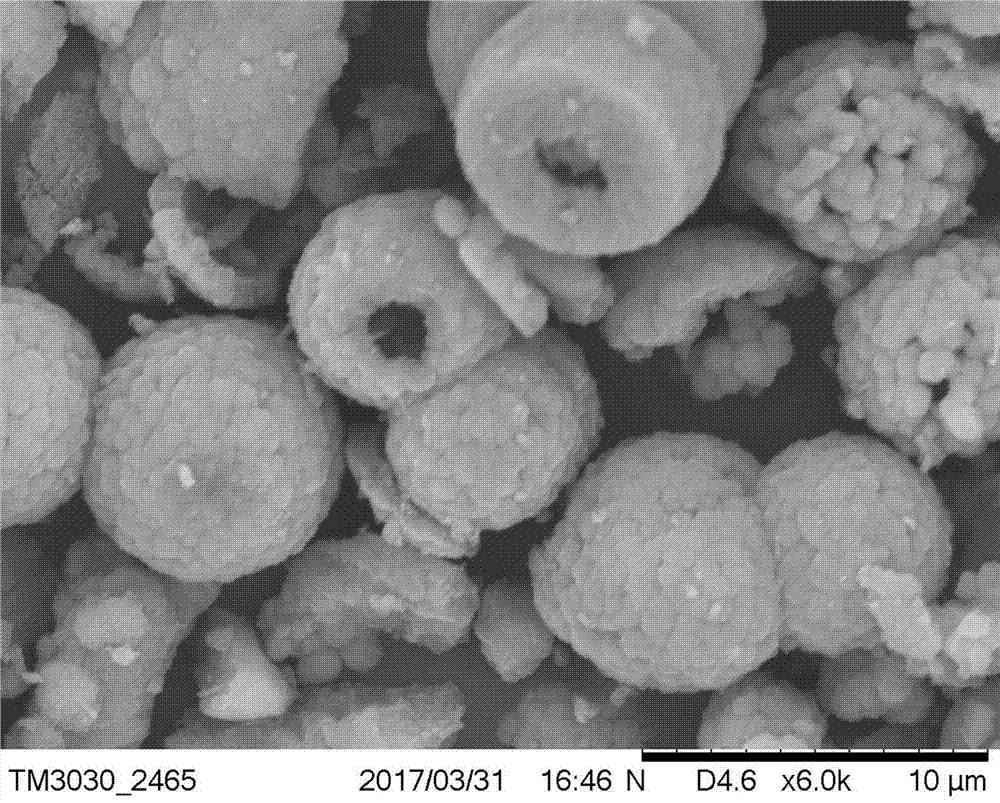

Image

Examples

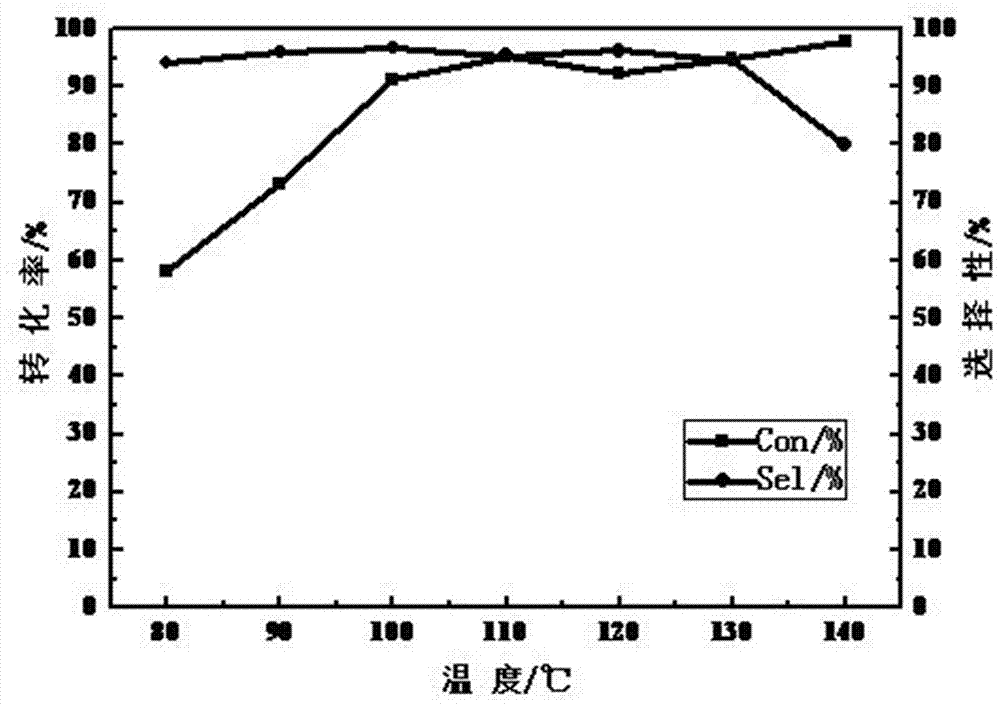

Embodiment 1

[0012] Example 1: The cycloaddition reaction of carbon dioxide and epoxide was carried out in a 25 mL stainless steel autoclave equipped with a magnetic stirrer. First, put 50mg of Cu-BTC catalyst and 20mmol of epoxide in the autoclave, add 20mg of co-catalyst (tetrabutylammonium bromide), feed a certain amount of carbon dioxide, and react at a temperature of 110°C and a pressure of 10bar for 6h.

Embodiment 2

[0013] Example 2: The cycloaddition reaction of carbon dioxide and epoxide was carried out in a 25 mL stainless steel autoclave equipped with a magnetic stirrer. First, 50 mg of Co-BTC catalyst and 20 mmol of epoxide were placed in a high-pressure reactor, 20 mg of cocatalyst (tetrabutylammonium bromide) was added, a certain amount of carbon dioxide was introduced, and the reaction was carried out at a temperature of 110 °C and a pressure of 10 bar for 6 h.

Embodiment 3

[0014] Example 3: The cycloaddition reaction of carbon dioxide and epoxide was carried out in a 25 mL stainless steel autoclave equipped with a magnetic stirrer. First, put 50mg of Ni-BTC catalyst and 20mmol of epoxide in a high-pressure reactor, add 20mg of co-catalyst (tetrabutylammonium bromide), feed a certain amount of carbon dioxide, and react at a temperature of 110°C and a pressure of 10bar for 6h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com