Preparation method of terbium-doped lithium magnesium phosphate photoexcitation luminous dosimeter

A light-stimulated luminescence and magnesium phosphate technology, which is applied to luminescent dosimeters, dosimeters, and luminescent materials, can solve difficult problems and achieve the effects of increased yield, reduced preparation difficulty and cost, and omission of grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

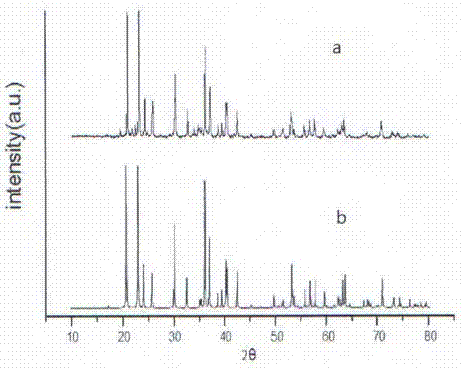

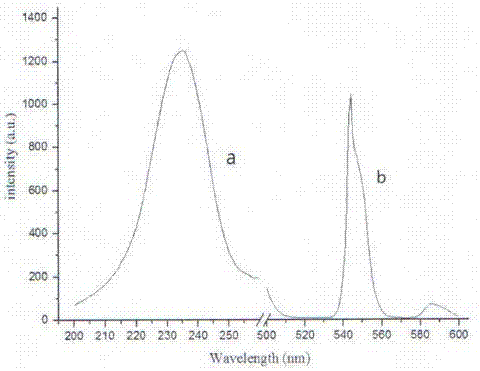

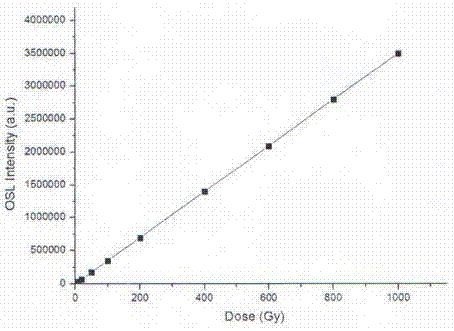

Embodiment 1

[0024] a. In the agate mortar, add the raw material LiOH·H 2 O 15.42g (0.37mol), Mg (NO 3 ) 2 ·6H 2 O 84.61g (0.33mol), NH 4 h 2 PO 4 36.42g (0.32mol), Tb 4 o 70.598g (0.25mol%) and H 3 BO 3 5.0g (0.08mol), put into an agate mortar and grind for 1h to obtain a gray paste mixture;

[0025] b. Put the mixed material obtained in step a into a corundum crucible, put it into a high-temperature sintering furnace, raise the temperature to a pre-burning temperature of 750°C at a heating rate of 2°C / min, keep it warm for 15 hours, and then lower it to room temperature with the furnace to obtain a white color LiMgPO 4 : Tb, B pre-fired material;

[0026] c. After the reaction, the white LiMgPO 4 :Tb,B The pre-fired material was taken out from the crucible, and then ground with a glass mortar to eliminate agglomeration to obtain white LiMgPO 4 : Tb, B powder;

[0027] d. Weigh 0.10 g of the powder obtained in step c and pour it into a one-way stainless steel stamping die ...

Embodiment 2

[0031] a. In the agate mortar, add the raw material LiOH·H 2 O 15.42g (0.37mol), Mg (NO 3 ) 2 ·6H 2 O 84.61g (0.33mol), NH 4 h 2 PO 4 36.42g (0.32mol), Tb 4 o 7 0.598g (0.25mol%) and H 3 BO 3 5.0g (0.08mol), put into an agate mortar and grind for 1h to obtain a gray paste mixture;

[0032] b. Put the mixed material obtained in step a into a corundum crucible, put it into a high-temperature sintering furnace, raise the temperature to a pre-burning temperature of 750°C at a heating rate of 2°C / min, keep it warm for 15 hours, and then lower it to room temperature with the furnace to obtain a white color LiMgPO 4 : Tb, B pre-fired material;

[0033] c. After the reaction, the white LiMgPO 4 :Tb,B The pre-fired material was taken out from the crucible, and then ground with a glass mortar to eliminate agglomeration to obtain LiMgPO 4 : Tb, B powder;

[0034] d. Weigh 0.10 g of the powder obtained in step c and pour it into a one-way stainless steel stamping die with...

Embodiment 3

[0038] a. In the agate mortar, add the raw material LiOH·H 2 O 15.42g (0.37mol), Mg (NO 3 ) 2 ·6H 2 O 84.61g (0.33mol), NH 4 h 2 PO 4 36.42g (0.32mol), Tb 4 o 7 0.598g (0.25mol%) and H 3 BO 3 5.0g (0.08mol), put into an agate mortar and grind for 1h to obtain a gray paste mixture;

[0039] b. Put the mixed material obtained in step a into a corundum crucible, put it into a high-temperature sintering furnace, raise the temperature to a pre-burning temperature of 750°C at a heating rate of 2°C / min, keep it warm for 15 hours, and then lower it to room temperature with the furnace to obtain a white color LiMgPO 4 : Tb, B pre-fired material;

[0040] c. After the reaction, the white LiMgPO 4 :Tb,B The pre-fired material was taken out from the crucible, and then ground with a glass mortar to eliminate agglomeration to obtain LiMgPO 4 : Tb, B powder;

[0041] d. Weigh 0.10 g of the powder obtained in step c and pour it into a one-way stainless steel stamping die with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com