Road surface pavement construction method with graphene thin film

A technology of graphene film and construction method, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problem of large manpower and material resources for asphalt pavement repair and maintenance, shortened service life of asphalt pavement, and structural damage of asphalt pavement To reduce the chance of rain erosion, strengthen asphalt pavement, and prevent cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

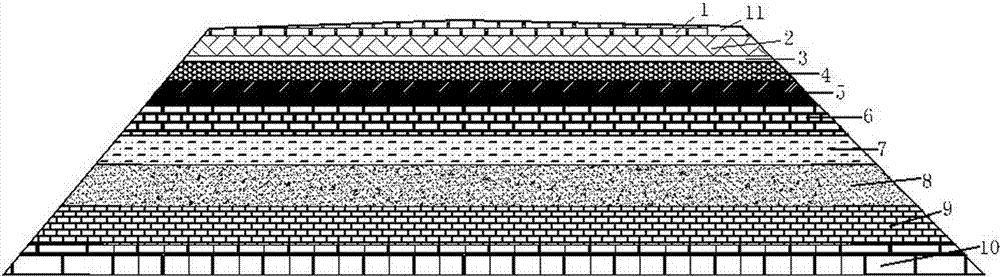

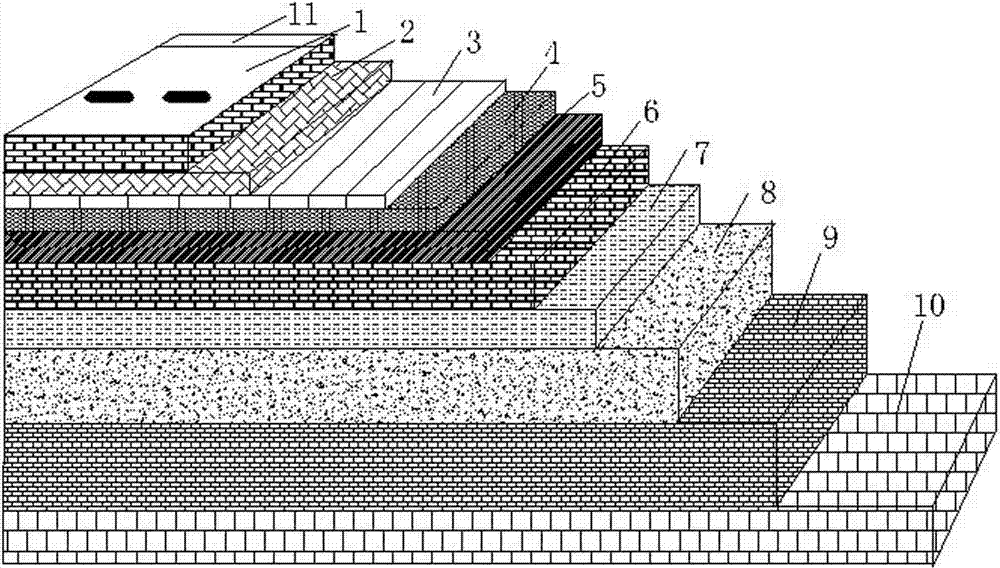

[0013] Embodiment 1: the fine-grained asphalt concrete thickness of the secondary road is 4cm, the Chinese asphalt concrete thickness is 6cm, the cement concrete crushed stone thickness is 20cm, and the graded crushed stone thickness is 20cm, and the 5mm graphene film is laid on the cement concrete crushed stone. between stone and Chinese asphalt concrete. The 20cm graded crushed stone and 20cm cement concrete crushed stone are paved according to the technical plan. The water-cement ratio of cement concrete is 0.56, and the sand rate is 33%; the mixing ratio of water, cement, sand and gravel is 1:1.69:3.44:0.56. Carry out maintenance after paving.

[0014] Before placing and laying the 5mm graphene film, the debris on the pavement base should be removed so that the diameter of dust, sharp protrusions and large particles cannot exceed 5mm. A 5mm graphene film has a length of 15m and a width of 10m. When laying, lay 5mm graphene film continuously according to the construction...

Embodiment 2

[0017] Embodiment 2: The thickness of the upper layer AC-13 fine-grained asphalt concrete of the pavement of the first-class highway is 5cm, the thickness of the middle surface layer AC-20 medium-grained asphalt concrete is 7cm, the thickness of the base cement gravel is 19cm, and the cushion layer is gravel The thickness is 38cm. A 5mm graphene film is laid between the base layer and the middle layer. A 38cm gravel cushion and a 19cm cement gravel base are paved according to the technical plan. A certain amount of gravel (generally not more than 50%) is added to the cement gravel soil. The compaction degree of the subbase is 95.9, and the water content is 4.1. The compaction degree of the base is 94.9, and the water content is 4.3.

[0018] When placing and laying 5mm graphene film, the sundries on the pavement base should be removed, so that the diameter of dust, sharp protrusions and large particles should not exceed 5mm. A 5mm graphene film has a length of 15m and a widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com