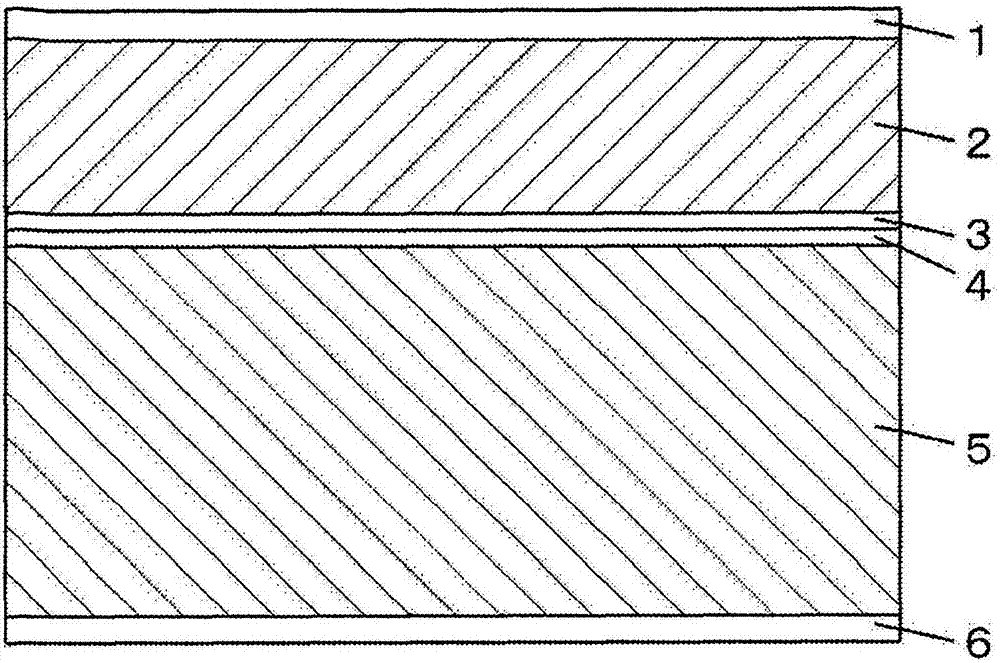

Hard coat laminate film

A hard coating, laminated film technology, applied in the direction of coating, layered products, synthetic resin layered products, etc., can solve the problems of surface hardness, insufficient rigidity, unpredictable OnePlasticSolution, etc., and achieve excellent surface hardness and rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0174] Hereinafter, although an Example demonstrates this invention, this invention is not limited to these Examples.

[0175] test methods

[0176] (1) Total light transmittance

[0177] The total light transmittance was measured using a nephelometer "NDH2000" (trade name) of Nippon Denshoku Kogyo Co., Ltd. in accordance with JIS K7361-1:1997.

[0178] (2) Haze

[0179] According to JIS K7136:2000, the haze was measured using the turbidity meter "NDH2000" (brand name) of Nippon Denshoku Kogyo Co., Ltd..

[0180] (3) Yellowness Index

[0181] According to JIS K7105:1981, the yellowness index was measured using the colorimeter "SolidSpec-3700" (trade name) of Shimadzu Corporation.

[0182] (4) Pencil hardness

[0183] According to JIS K5600-5-4, the pencil hardness was measured using the pencil "ユニ" (trade name) of Mitsubishi Pencil Co., Ltd. under the condition of a load of 750 g.

[0184] (5) Shrinkage start temperature (heat-resistant dimensional stability)

[0185]...

example 1

[0238] Use above-mentioned (α-1), use to have 50mm extruder (install the W type screw thread of L / D=29, CR=1.86); The T type die head of die head width 680mm; ) and a mirror belt (second mirror body) to squeeze the melted film into a traction coiler to obtain a film with a thickness of 500 μm and a good surface appearance. At this time, the setting conditions are set temperature C1 / C2 / C3 / AD=280 / 300 / 320 / 320°C of the extruder; set temperature of the T-shaped die head is 320°C; 1.0mm; the set temperature of the mirror roller is 140°C; the set temperature of the mirror belt is 120°C; the extrusion pressure of the mirror belt is 1.4MPa; the pulling speed is 3.6m / min. Total light transmittance, haze and yellowness index were measured. The results are shown in Table 1. Next, after corona discharge treatment was applied to both surfaces of the obtained film, a hard coat layer was formed on one surface to have a thickness of 25 μm after curing using the above-mentioned (γ2-1) using a...

example 2

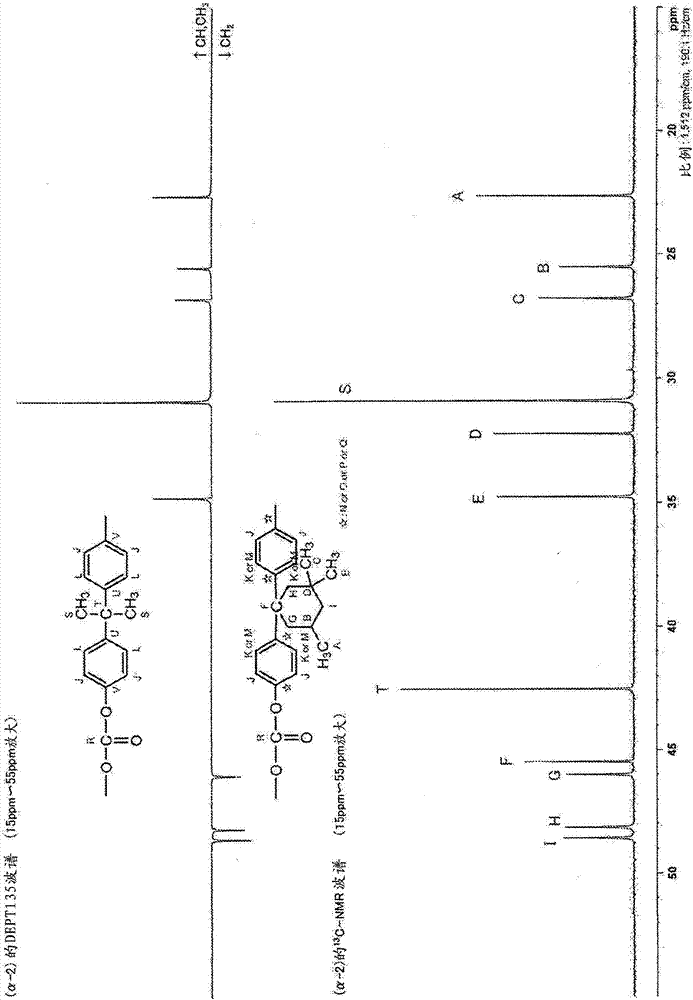

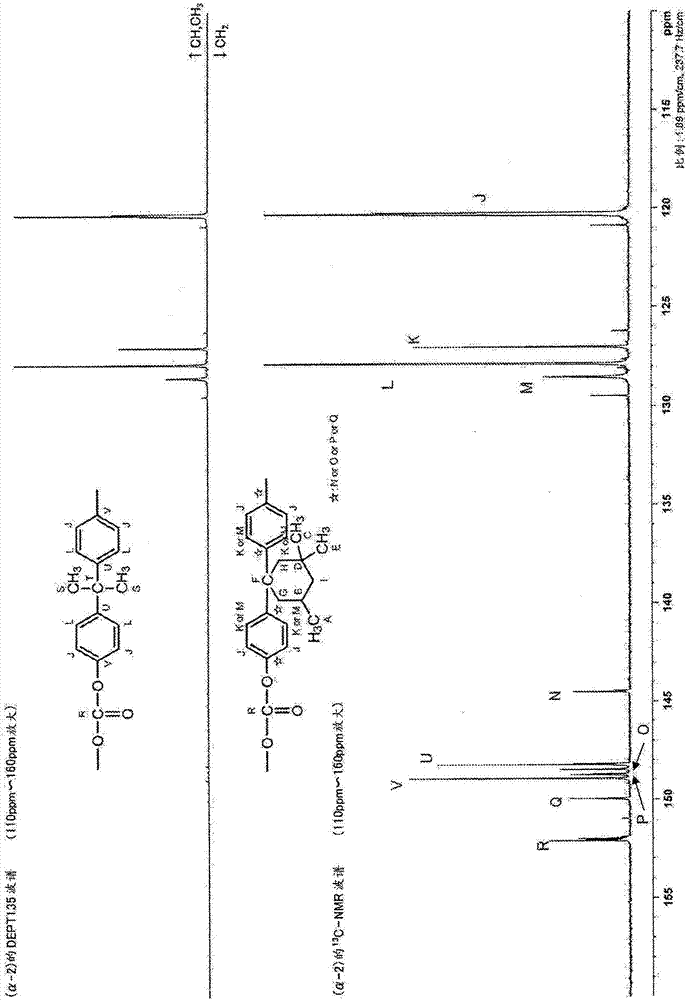

[0240] Formation of the hard-coat laminated film and evaluation of physical properties were performed in the same manner as in Example 1 except that the above-mentioned (α-2) was used instead of the above-mentioned (α-1). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com