Method for online real-time removal of ammonia in indoor air through grape wine composition

A technology for indoor air and wine, which is applied in the field of indoor air purification, can solve the problems of high operating costs of the breakpoint chlorination method, large area occupied by the biological method, and expensive purification equipment, and achieves simple preparation and use methods, low cost, The effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The ammonia online real-time removal composition is prepared by mixing the following components in volume percentage:

[0034] 828 wine 2.5%;

[0035] Water 97.5%.

[0036] After the 828 wine and water are evenly mixed, they can be automatically packaged and stored in the warehouse.

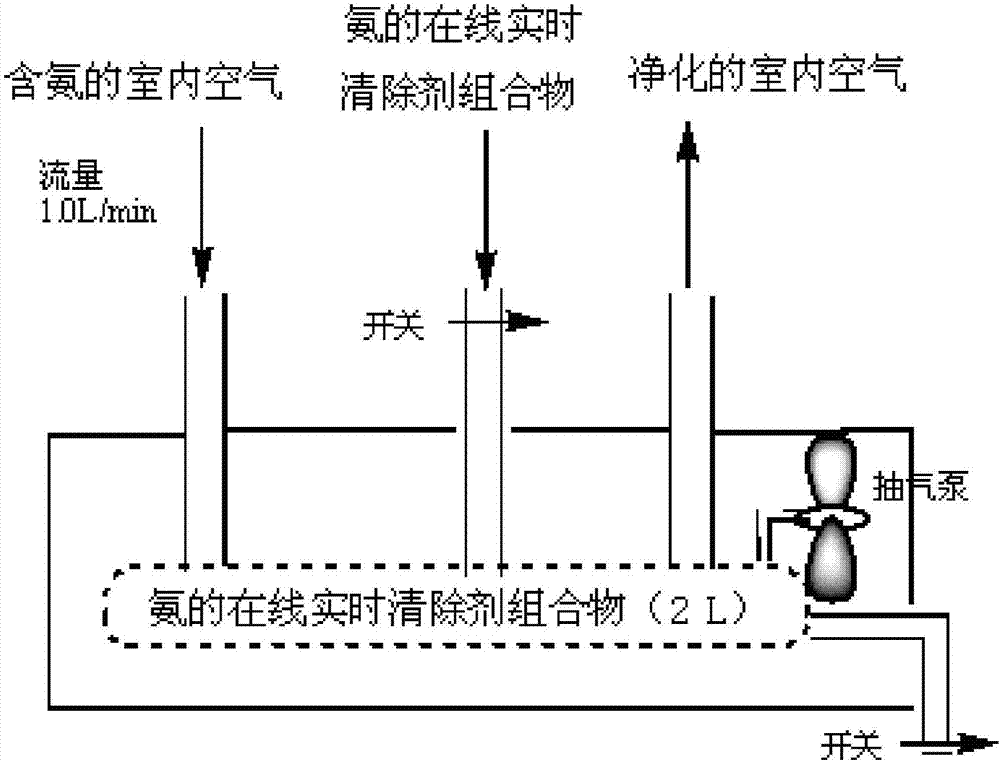

[0037] Use 2.0L ammonia online real-time cleaning composition aqueous solution to place figure 1 The shown device removes ammonia in the indoor air online in real time, and the application effect is shown in Table 1.

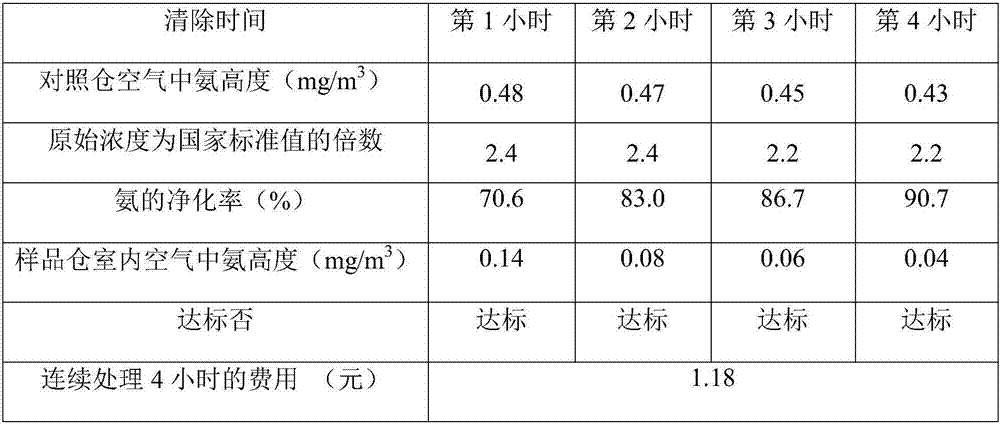

[0038] The effect and cost of practical application of the ammonia on-line real-time removal composition aqueous solution of the embodiment 1 of table 1

[0039]

[0040] As can be seen from Table 1, the ammonia on-line real-time removal composition can be treated for 1 hour to reach the standard; for 160m 2 In a luxury house, the ammonia concentration in the indoor air exceeds the standard by 5 times, and the standard can be reached after 1 hour of treatment, and the...

Embodiment 2

[0042] The ammonia online real-time removal composition is prepared by mixing the following components in volume percentage:

[0043] 828 wine 3.5%;

[0044] Water 96.5%.

[0045] After the 828 wine and water are evenly mixed, they can be automatically packaged and stored in the warehouse.

[0046] Use 2.0L ammonia online real-time cleaning composition aqueous solution to place figure 1 The shown device removes ammonia in the indoor air online in real time, and the application effect is shown in Table 2.

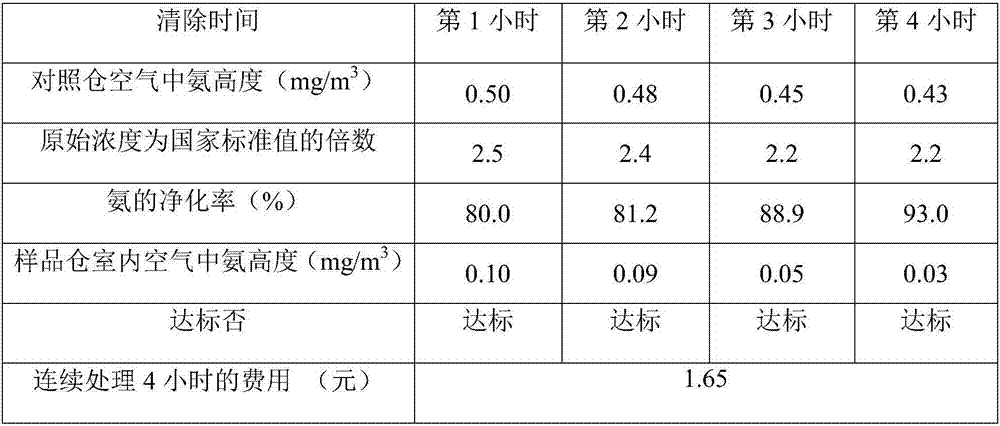

[0047] Table 2 Effect and cost of actual application of ammonia online real-time removal composition aqueous solution

[0048]

[0049]As can be seen from Table 2, the ammonia on-line real-time removal composition can be treated for 1 hour to reach the standard; for 160m 2 In a luxury house, the ammonia concentration in the indoor air exceeds the standard by 5 times, and the standard can be reached after 1 hour of treatment, and the cost of continuous treatment for 4 ...

Embodiment 3

[0051] The ammonia online real-time removal composition is prepared by mixing the following components in volume percentage:

[0052] 5% for 828 wines;

[0053] Water 95%.

[0054] After the 828 wine and water are evenly mixed, they can be automatically packaged and stored in the warehouse.

[0055] Use 2.0L ammonia online real-time cleaning composition aqueous solution to place figure 1 The shown device removes ammonia in the indoor air online in real time, and the application effect is shown in Table 3.

[0056] Table 3 Effect and cost of actual application of ammonia online real-time removal composition aqueous solution

[0057]

[0058] As can be seen from Table 3, the ammonia on-line real-time removal composition can be treated for 1 hour to reach the standard; for 160m 2 In a luxury house, the ammonia concentration in the indoor air exceeds the standard by 5 times, and the standard can be reached after 1 hour of treatment, and the cost of continuous treatment for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com