Method for preparing non-shrinkage grouting material

A grouting material and non-shrinkage technology, which is applied in the field of preparation of non-shrinking grouting material, can solve the problems of poor strength, easy shrinkage, easy cracking, etc., and achieve the effect of improving later strength, avoiding cracking, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

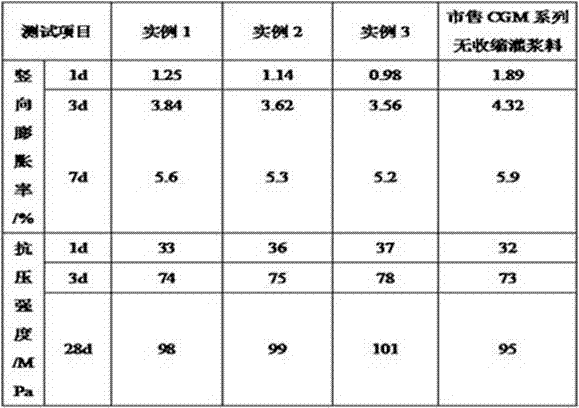

example 1

[0020] First, weigh 1kg of rubber grass root and wash it with water for 3 times, put the washed rubber grass root in a tissue crushing machine and pulverize it for 40 minutes to obtain rubber grass root fragments, take 600g of rubber grass root fragments and add them to a beaker, then add 100g of refinery waste water to the beaker Treat the activated sludge in the secondary sedimentation tank, stir and mix for 1min, then move it to a dark place for fermentation for 5 days. After the fermentation is completed, the fermentation product is obtained. At the same time, weigh 1kg of quartz sand and 600g of metakaolin, add them to the pulverizer, and pass through an 80-mesh sieve. , to obtain mixed powder, take 1kg of mixed powder and put it into the muffle furnace, control the temperature of the muffle furnace to 900°C, keep the temperature for calcination for 1h, and after the calcination is completed, cool the calcined product to room temperature with the furnace to obtain the activ...

example 2

[0022] First weigh 1kg of rubber grass root and wash it with water for 4 times, put the washed rubber grass root in a tissue crushing machine and pulverize it for 45 minutes to obtain rubber grass root fragments, take 700g of rubber grass root fragments and add them to a beaker, then add 150g of refinery waste water to the beaker Treat the activated sludge in the secondary sedimentation tank, stir and mix for 2 minutes, then transfer to a dark place for fermentation treatment for 7 days. After the fermentation is completed, the fermentation product is obtained. At the same time, weigh 1kg of quartz sand and 700g of metakaolin, add them to the pulverizer, and pass through a 90-mesh sieve. , to obtain mixed powder, take 1kg of mixed powder and add it to the muffle furnace, control the temperature of the muffle furnace to 950°C, keep the heat for calcination for 1h, and after the calcination is completed, cool the calcined product to room temperature with the furnace to obtain the ...

example 3

[0024]First, weigh 2kg of rubber grass root and wash it with water for 5 times, put the cleaned rubber grass root in a tissue crushing machine and pulverize it for 50 minutes to obtain rubber grass root fragments, take 800g of rubber grass root fragments and add them to a beaker, then add 200g of refinery wastewater to the beaker Treat the activated sludge in the secondary sedimentation tank, stir and mix for 3 minutes, then transfer to a dark place to ferment for 8 days. After the fermentation is completed, the fermentation product is obtained. At the same time, weigh 2kg of quartz sand and 800g of metakaolin, add them to the pulverizer, and pass through a 100-mesh sieve. , to obtain mixed powder, take 2kg of mixed powder and put it into a muffle furnace, control the temperature of the muffle furnace to 1000°C, keep it for calcination for 2 hours, and after the calcination is completed, cool the calcined product to room temperature with the furnace to obtain an activated powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com