Method for improving strength and durability of cement-based materials by medium and low frequency vibration

A cement-based material, low-frequency vibration technology, applied in the field of building materials, can solve problems such as short vibration time, and achieve the effects of increasing compressive strength, reducing porosity, and shortening setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for modifying the strength and durability of cement-based materials by medium and low frequency vibrations, the steps are as follows:

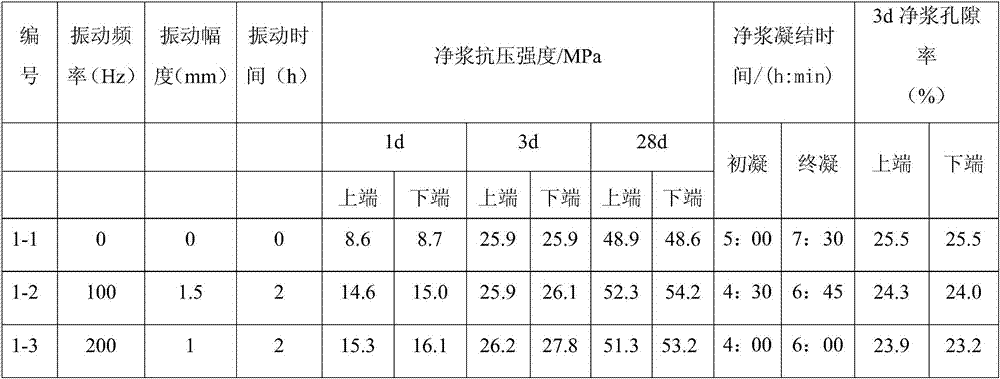

[0017] Put ordinary Portland cement, water, first-grade fly ash, S95 mineral powder, and polycarboxylate superplasticizer into a mixer in a mass ratio of 100:60:67:12:1, and stir slowly for 2 minutes, then Stir quickly for 2 minutes to obtain concrete slurry; place a 40mm (length) × 40mm (width) × 160mm (height) 3-unit steel mold on a four-dimensional space vibration table, and after pouring the concrete slurry in the mold, set the four-dimensional The vibration frequency of the space vibrating table is 100Hz (200Hz), the vibration amplitude is 1.5mm (1mm), and the vibration time is 2 hours. The sample was used as the comparative experimental group (1-1). The experimental performance results are shown in Table 1:

[0018] Table 1

[0019]

[0020] It can be seen from Table 1 that, for 1d strength, the strength of the uppe...

Embodiment 2

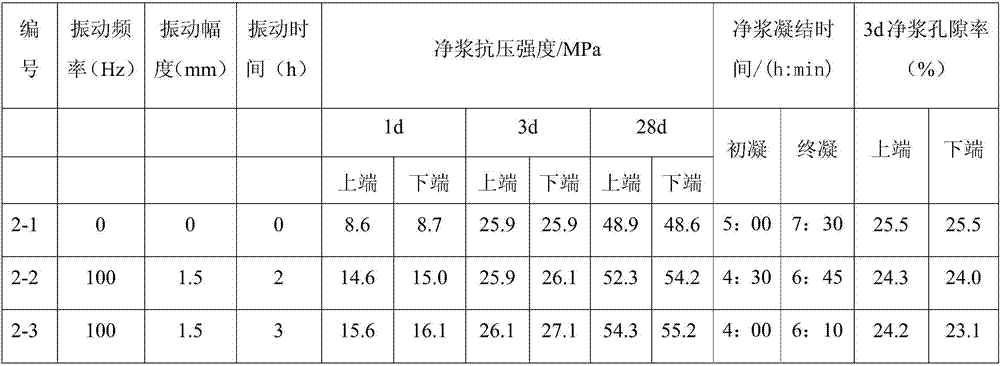

[0022] A method for modifying the strength and durability of cement-based materials by medium and low frequency vibrations, the steps are as follows:

[0023] Put ordinary Portland cement, water, first-grade fly ash, S95 mineral powder, and polycarboxylate superplasticizer into a mixer in a mass ratio of 100:60:67:12:1, and stir slowly for 2 minutes, then Stir quickly for 2 minutes to obtain concrete slurry; place a 40mm (length) × 40mm (width) × 160mm (height) 3-unit steel mold on a four-dimensional space vibration table, and after pouring the concrete slurry in the mold, set the four-dimensional The vibration frequency of the space vibration table is 100Hz, the vibration amplitude is 1.5mm, and the vibration time is 2 hours and 3 hours respectively. The vibration table is started to simulate the vibration test, and the sample of 40mm×40mm×160mm is prepared under the static condition as Compare the experimental group (2-1). The experimental performance results are shown in T...

Embodiment 3

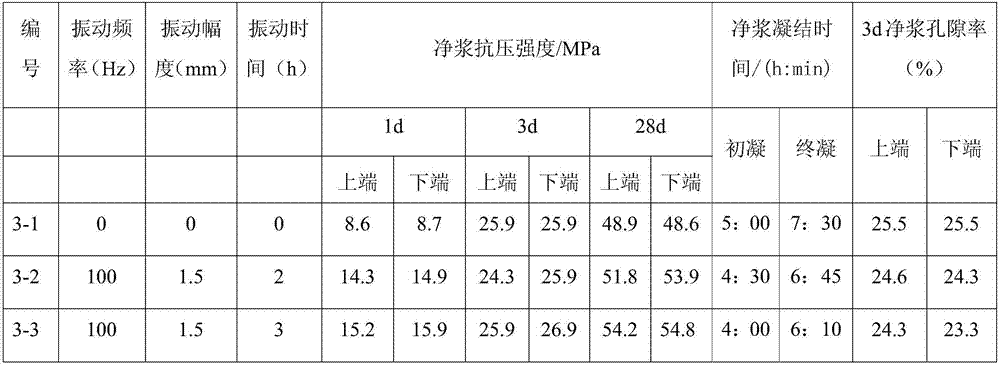

[0028] A method for modifying the strength and durability of cement-based materials by medium and low frequency vibrations, the steps are as follows:

[0029] Put ordinary Portland cement, water, first-grade fly ash, S95 mineral powder, and polycarboxylate superplasticizer into a mixer in a mass ratio of 100:50:50:15:1, and stir slowly for 2 minutes, then Stir quickly for 2 minutes to obtain concrete slurry; place a 40mm (length) × 40mm (width) × 160mm (height) 3-unit steel mold on a four-dimensional space vibration table, and after pouring the concrete slurry in the mold, set the four-dimensional The vibration frequency of the space vibration table is 100Hz, the vibration amplitude is 1.5mm, and the vibration time is 2 hours and 3 hours respectively. The vibration table is started to simulate the vibration test, and the sample of 40mm×40mm×160mm is prepared under the static condition as Compare the experimental group (3-1). The experimental performance results are shown in T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com