V belt capable of reducing dynamic heat build-up

A heat-generating and dynamic technology, applied in the field of rubber V-belt production, can solve problems such as shortening and decreasing service life, and achieve the effect of increasing service life, reducing dynamic heat generation and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

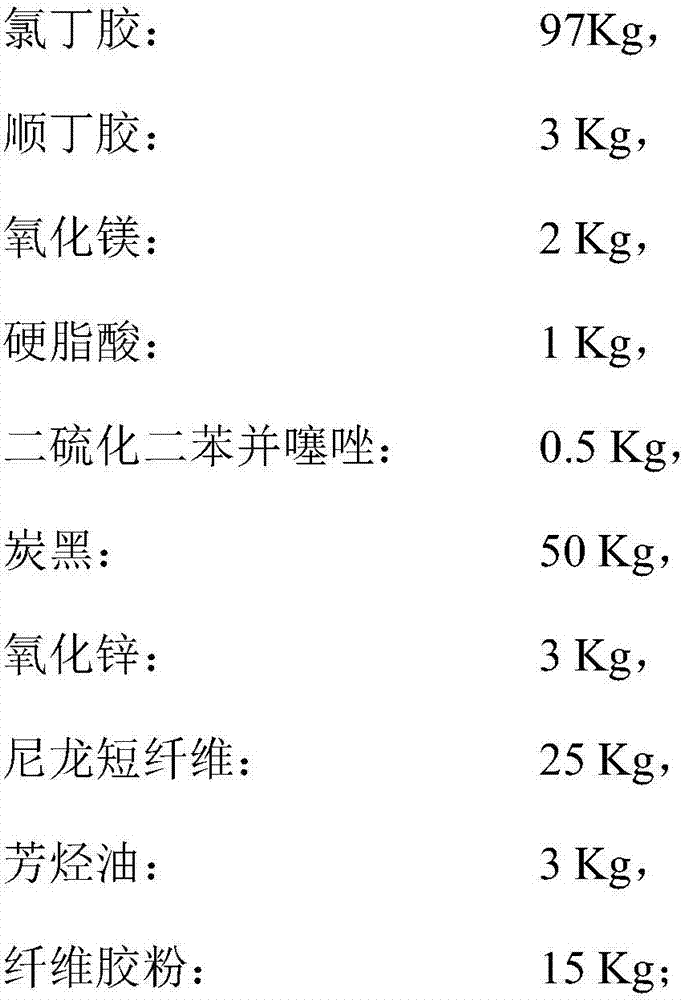

Embodiment 1

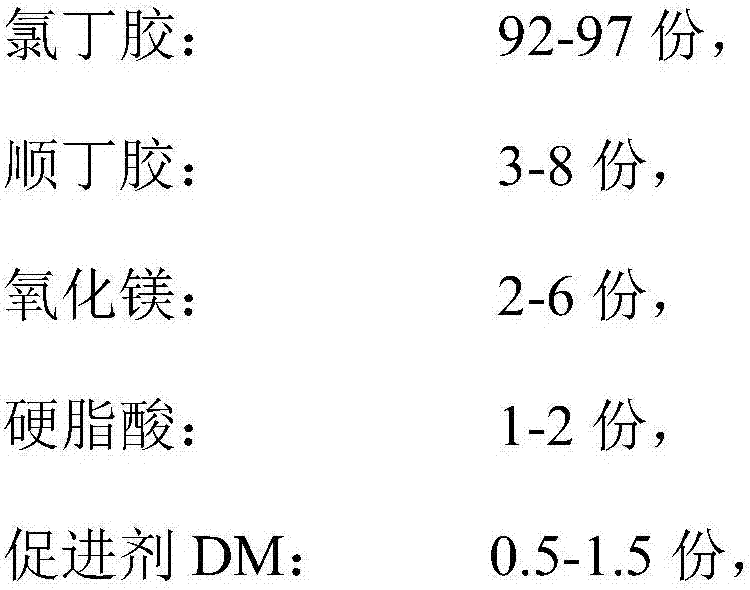

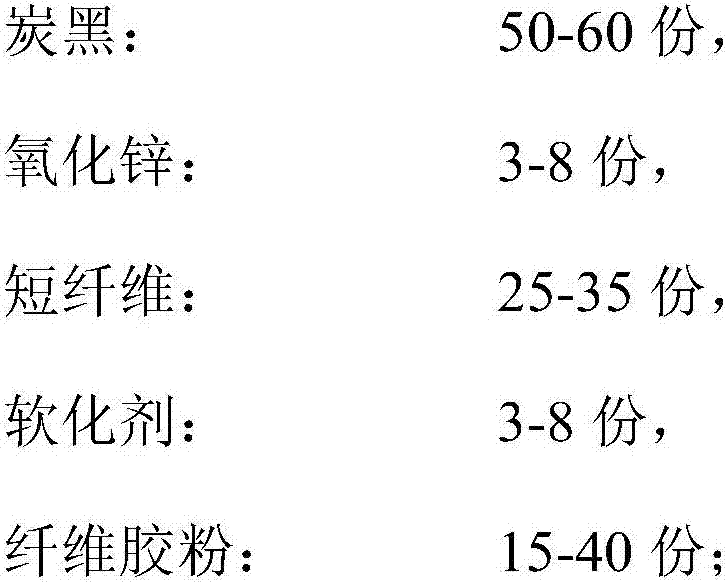

[0013] Embodiment 1: the V-belt that can reduce dynamic heat generation, each component is composed as follows:

[0014]

[0015] The order in which the components are added to the internal mixer is as follows: Neoprene, butadiene rubber, short fiber and fiber rubber powder are added first, the initial temperature of the internal mixer is controlled at 80°C, and the continuous refining time is 3 minutes. The second step Add magnesium oxide, stearic acid, dibenzothiazole disulfide, carbon black and aromatic oil, the temperature of the internal mixer is controlled at 110°C, and the continuous refining time is 2 minutes. In the third step, zinc oxide is added, and the internal mixer The temperature is controlled at 115°C, and the zinc oxide is added 30 seconds before the internal mixer starts debinding. In fact, the refining time of the third step is only 30 seconds.

[0016] The obtained V-belt is tested, and its breaking strength (longitudinal) is 10.86Mpa, and the breaking ...

Embodiment 2

[0020] V-belts that can reduce dynamic heat generation, the composition of each component is as follows:

[0021]

[0022] The order in which the components are added to the internal mixer is as follows: Neoprene, butadiene rubber, short fiber and fiber rubber powder are added first, the initial temperature of the internal mixer is controlled at 80°C, and the continuous refining time is 4 minutes. The second step Add magnesium oxide, stearic acid, dibenzothiazole disulfide, carbon black and aromatic oil, the temperature of the internal mixer is controlled at 110°C, and the continuous refining time is 2.5 minutes. In the third step, zinc oxide is added. The temperature is controlled at 115°C, and the zinc oxide is added 30 seconds before the internal mixer starts debinding. In fact, the refining time of the third step is only 30 seconds.

[0023] The obtained V-belt is tested, and its breaking strength (longitudinal) is 10.6Mpa, and the breaking elongation (longitudinal) is ...

Embodiment 3

[0027] In order to illustrate the effect, a comparative experiment is now carried out on two V-belts with and without fiber rubber powder. The composition and test data of the two components are as follows:

[0028]

[0029]

[0030] Use the No. 1 V-belt and the No. 2 V-belt to produce two identical motorcycle V-belts respectively. The model is 669×18×30, that is, the length of the belt pitch is 669mm, the width is 18mm, and the wedge angle is 30° to make two wheels. For the comparative test of transmission heat generation, the size of the driving wheel and the driven wheel is in accordance with GB / T18860-2015, the speed of the driving wheel is 5500 rpm, the load of the driven wheel is 6kw, and the tension is 720N, which is constant. At an ambient temperature of 25°C, conduct a belt temperature test after running for 1 hour, and use an infrared thermometer to measure the surface temperature of the V-belt. Test conclusion: the temperature rise of No. 1 V-belt is 145°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com