ternary semiconductor pbsns 3 Nanocrystal and preparation method thereof

A semiconductor and nanocrystal technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of unfriendly environment, low nanocrystal yield, unfavorable large-scale production, etc., achieve good optoelectronic performance and simple preparation process , to achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

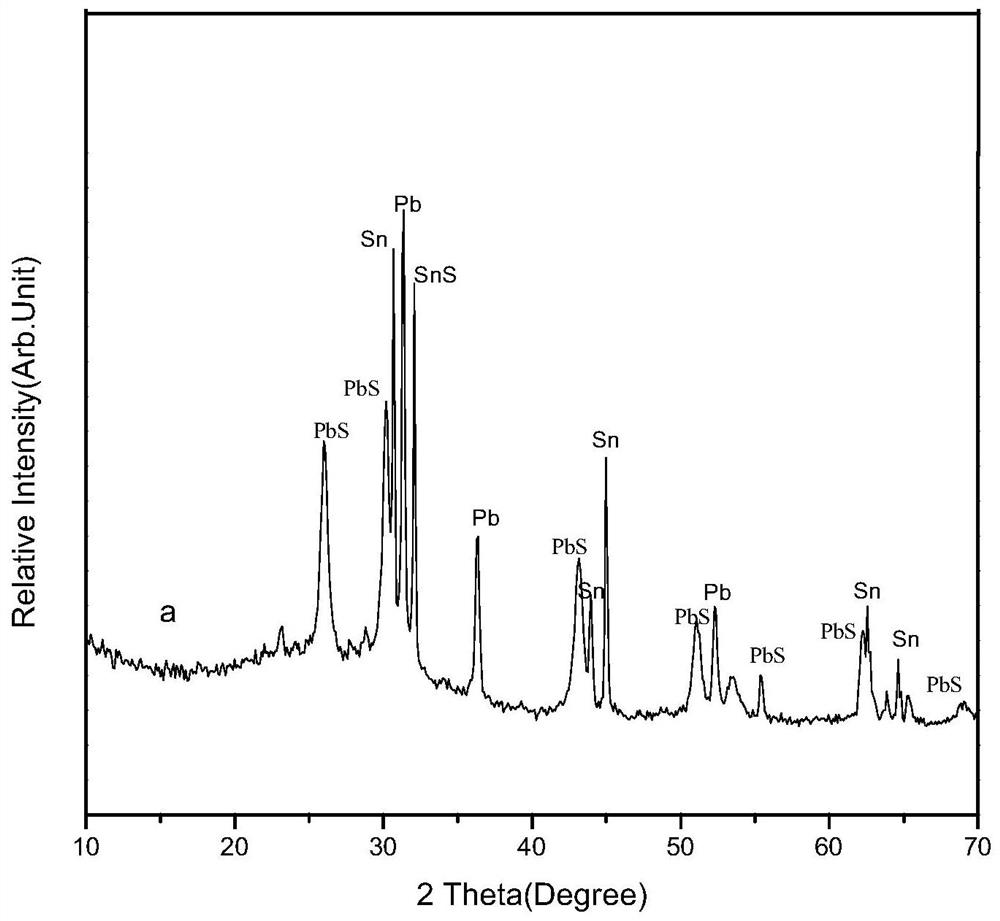

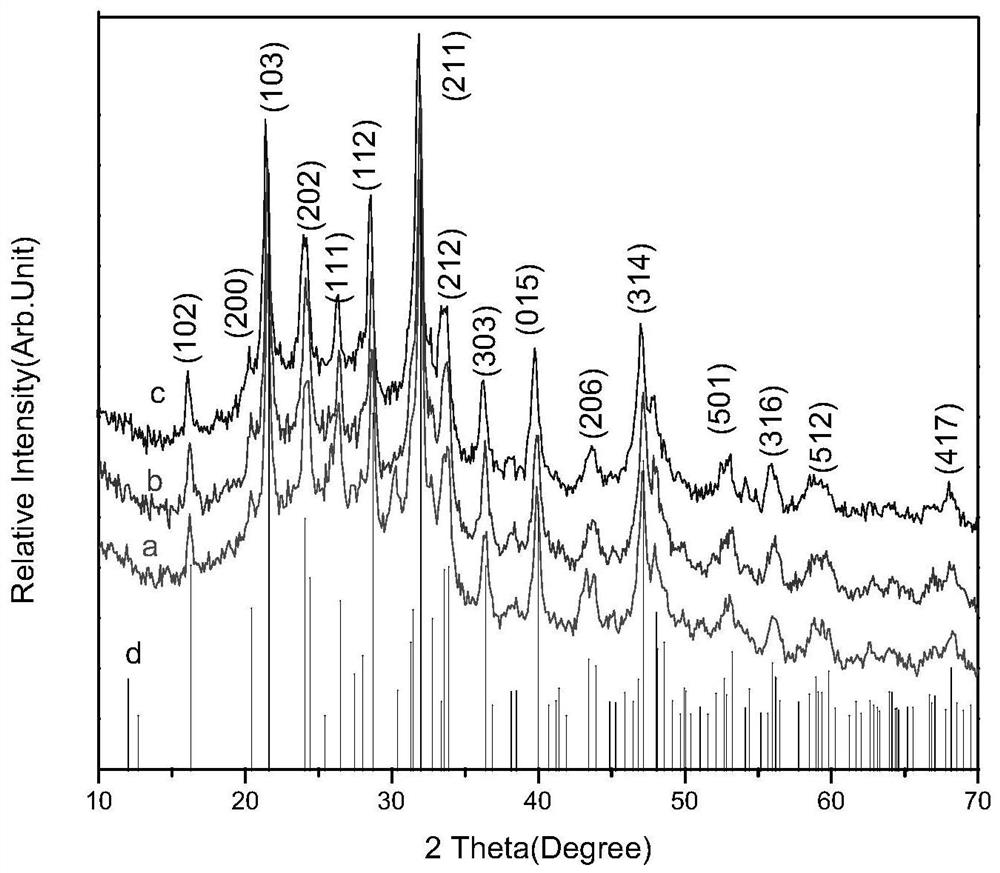

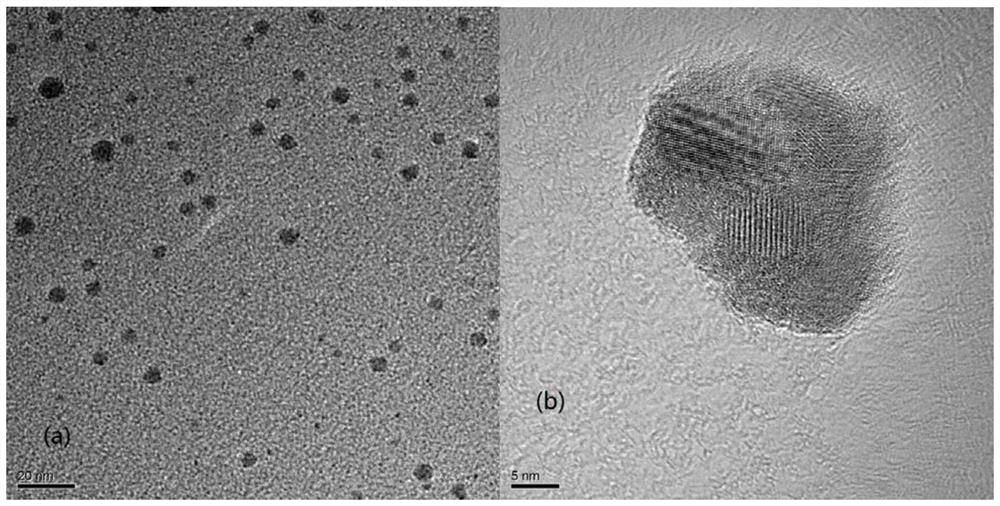

[0023] Weigh 7.9671g, 4.5646g and 2.4684g of elemental Pb, Sn and S powder respectively (the purity is above 99.9wt%), the weighing error is ±0.0002g, put the weighed sample in the ball mill jar and seal it , A ball mill with a diameter ranging from 2-12mm has been added in advance before the sample is placed, and the mass ratio of the ball mill to the powder mixture is set at 10:1-15:1. Put it in the glove box (full of inert gas), open it and let it stand to remove the air in the jar, seal the jar after 2 hours, take it out and install it on a SPEX8000 ball mill for ball milling, respectively at 1h, 5h, 10h, 20h and 40 hours Take a small amount of powder (the sampling process should be carried out in a glove box to avoid side reactions from entering the tank), and then perform XRD tests on samples of different time periods, and the XRD patterns are as follows: figure 1 and figure 2 shown. Then the resulting semiconductor nanocrystals were coated with alcohol and organic ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com