Method for improving uniformity of pattern critical dimensions in photoetching process

A key dimension, lithography process technology, applied in microlithography exposure equipment, patterned surface photoengraving process, photoengraving process exposure device and other directions, can solve the problem that cannot eliminate the influence of local pattern density on CD changes question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

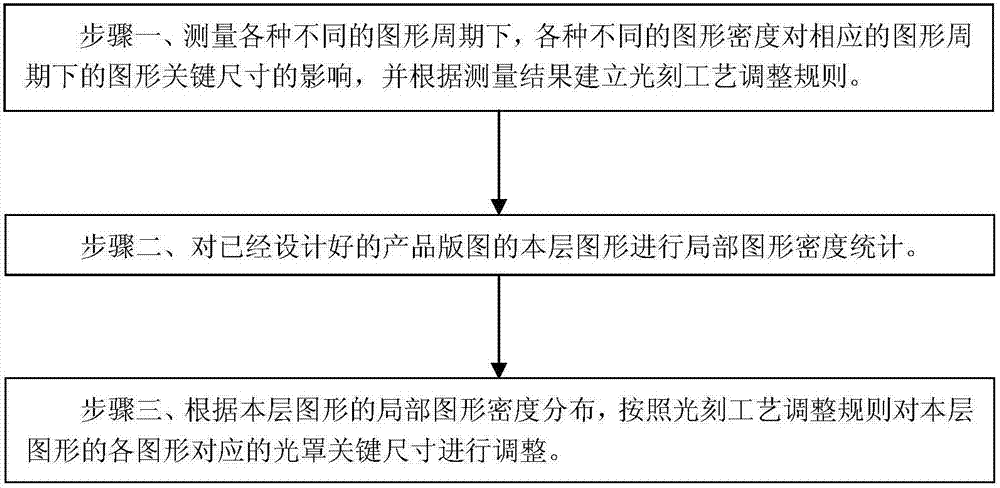

[0034] like figure 1 As shown, it is a flow chart of the method of the embodiment of the present invention. The method of improving the uniformity of the key dimension of the pattern in the lithography process according to the embodiment of the present invention includes the following steps:

[0035] Step 1: Measure the influence of various local pattern densities on the key dimensions of the pattern under the corresponding pattern period under various different pattern cycles, and establish a lithography process adjustment rule according to the measurement result; the lithography process adjustment rule It is ensured that the key dimensions of each pattern at different local pattern densities in each pattern cycle tend to be the same as the design requirements after the lithography process is completed, and the influence of different local pattern densities on the key dimensions of the pattern is eliminated.

[0036] In the method of the embodiment of the present invention, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com