Time-domain analysis method for dynamic temperature difference power generation system segmented on basis of temperature difference thermocouple material

A technology of thermocouple and thermoelectric power generation, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., and can solve problems that cannot be used to analyze the transient process of dynamic thermoelectric power generation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further illustrate the present invention, please refer to the accompanying drawings

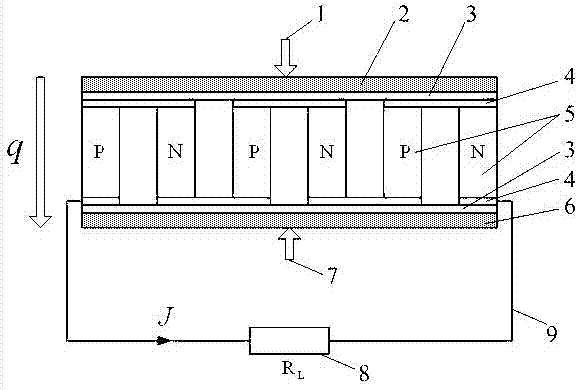

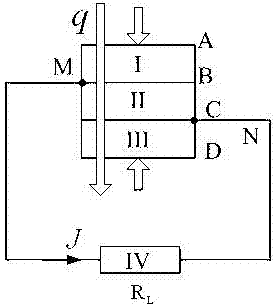

[0054] like figure 1 As shown, the thermoelectric power generation system consists of a hot end radiator 2 in contact with a heat source 1, a ceramic sheet 3, a guide sheet 4 and a pair of semiconductor thermocouples 5, a cold end radiator 6 in contact with a cold source 7, and a ceramic sheet 3 And deflector 4 composition. In order to obtain a higher electromotive force, the thermoelectric power generation system is composed of d pairs of semiconductor thermocouples 5 connected in series with the load resistor 8 through a high-conductivity guide plate 4 and a metal wire 9, and sandwiched between a thermocouple with good thermal conductivity and electrical insulation. between two ceramic sheets 3 parallel to each other. The heat flow q flows through the heat sink 2 at the hot end, the ceramic sheet 3 and the flow guide 4, d pairs with the semiconductor thermocouple 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com