High temperature resistance cable for mobile base station

A mobile base station, high temperature resistant technology, applied in the field of high temperature resistant cables, can solve the problems of poor strength, cracking of outer conductors, increased cost, etc., and achieve the effect of superior bending performance, adapting to large gain and adapting to miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

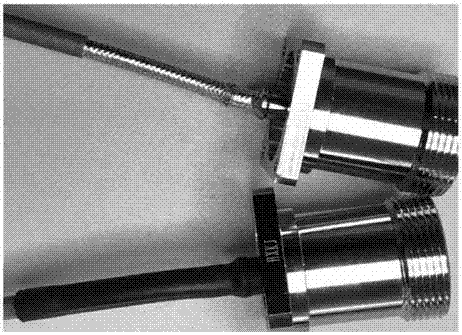

Embodiment 1

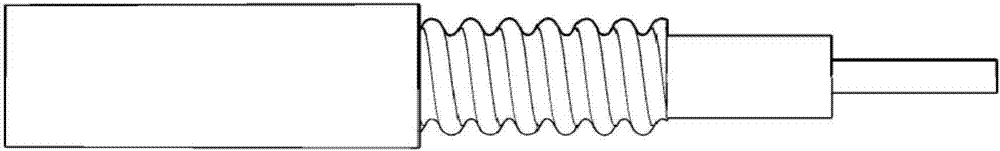

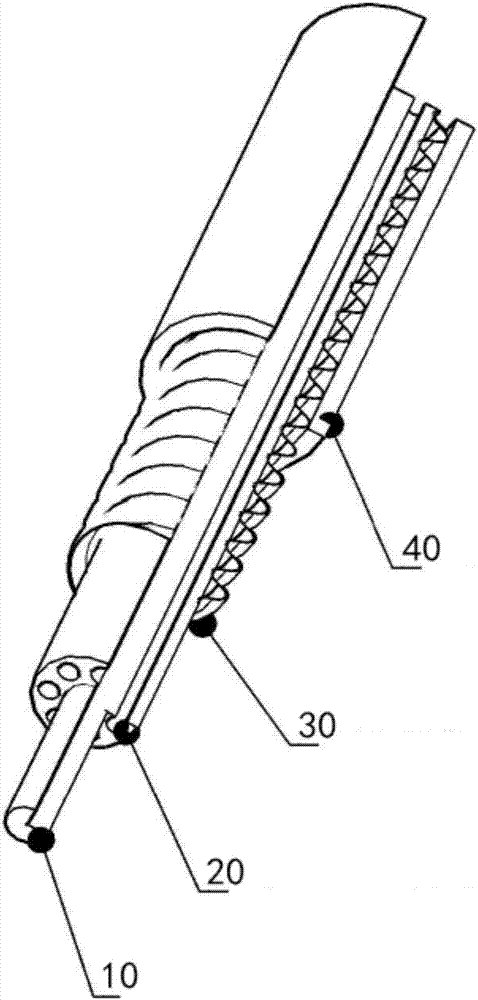

[0031] The high temperature resistant cable of this embodiment comprises a silver-plated copper wire inner conductor, a PTFE insulation layer with seven hollow channels parallel to the extension direction of the inner conductor symmetrically formed around the inner conductor, a spiral copper tube and an LSZH resistor. Burn polyolefin. Wherein, the diameter of the inner conductor of the silver-plated copper wire is 1.15±0.02 mm, and the thickness of the silver-plated layer is greater than 1 μm. The outer diameter of the PTFE insulating layer is 3.00±0.05mm, and there are 7 hollow channels symmetrically distributed, and the diameter of each hollow channel is 0.3-0.5mm. The outer diameter of the threaded copper pipe is 4.25±0.10mm. The outer diameter of the sheath is 5.20±0.10mm.

Embodiment 2

[0033]The high-temperature resistant cable of this embodiment includes a silver-plated copper wire inner conductor, a PTFE insulation layer with seven hollow channels parallel to the extension direction of the inner conductor symmetrically formed around the inner conductor, a spiral copper tube, and a perfluorinated copper tube. Ethylene propylene copolymer FEP. Wherein, the diameter of the inner conductor of the silver-plated copper wire is 1.15±0.02 mm, and the thickness of the silver-plated layer is greater than 1 μm. The outer diameter of the PTFE insulating layer is 3.00±0.05mm, and there are 7 hollow channels symmetrically distributed, and the diameter of each hollow channel is 0.3-0.5mm. The outer diameter of the threaded copper pipe is 4.25±0.10mm. The outer diameter of the sheath is 5.00±0.10mm.

[0034] According to the principle of coaxial cable signal transmission, the transmission attenuation of the cable is mainly caused by the heating of the inner conductor, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com