Charger

A technology of chargers and circuits, applied in current collectors, different battery charging, electric vehicles, etc., can solve the problems of low power loss, large power loss, and short service life of lead-acid batteries, so as to prolong the service life and reduce power loss Low, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

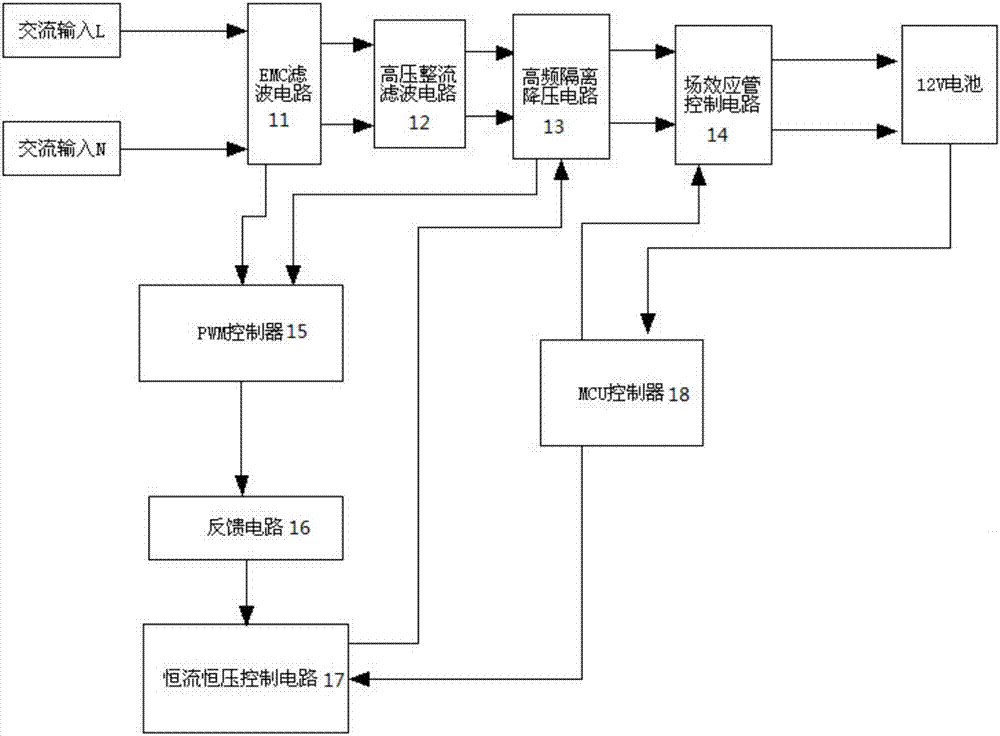

[0031] Such as figure 1 As shown, the present invention provides a charger, and the charger includes: an AC power input terminal, an EMC filter circuit 11, a high-voltage rectification filter circuit 12, a high-frequency isolation step-down circuit 13, a field effect tube control circuit 14, and a PWM control circuit. Device 15, feedback circuit 16, constant current and constant voltage control circuit 17, MCU controller 18 and charging output terminal.

[0032] EMC filter circuit 11 is electrically connected with high voltage rectification filter circuit 12 and PWM controller 15 respectively; The voltage control circuit 17 is electrically connected; the feedback circuit 16 is electrically connected with the PWM controller 15 and the constant current constant voltage control circuit 17 respectively; the MCU controller 18 is respectively connected with the constant current constant voltage control circuit 17, the field effect tube control circuit 14 and the The charging output...

Embodiment 2

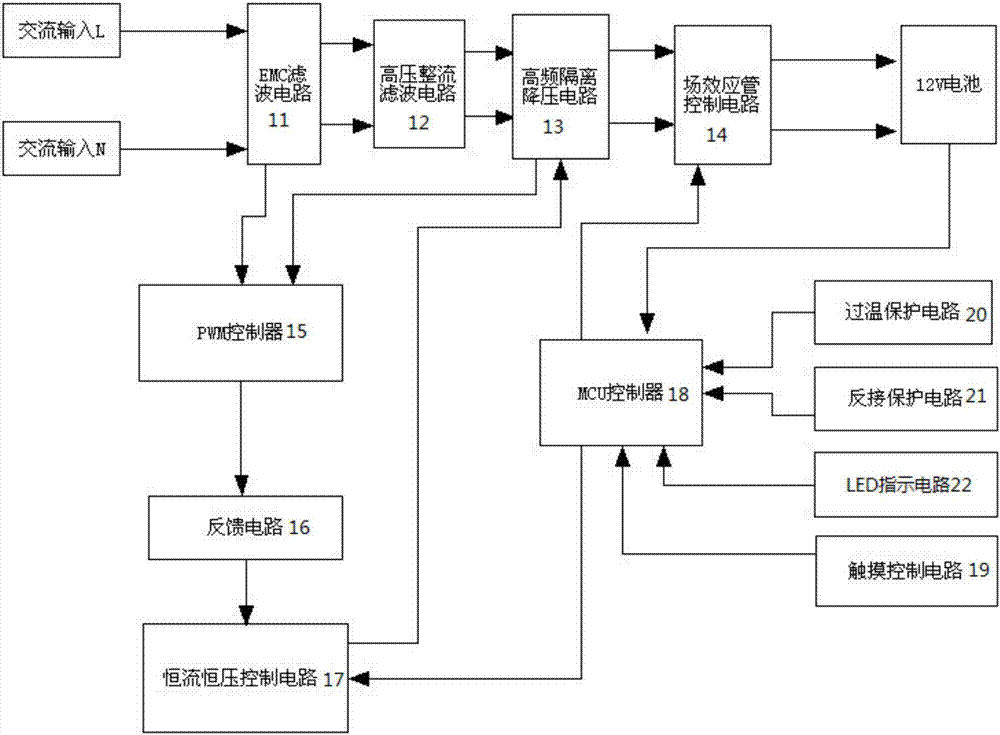

[0040] Such as figure 2 As shown, the present invention provides a charger, and the charger includes: an AC power input terminal, an EMC filter circuit 11, a high-voltage rectification filter circuit 12, a high-frequency isolation step-down circuit 13, a field effect tube control circuit 14, and a PWM control circuit. Device 15, feedback circuit 16, constant current and constant voltage control circuit 17, MCU controller 18, touch control circuit 19, over-temperature protection circuit 20, reverse connection protection circuit 21, LED indicator circuit 22 and charging output terminal.

[0041] EMC filter circuit 11 is electrically connected with high voltage rectification filter circuit 12 and PWM controller 15 respectively; The voltage control circuit 17 is electrically connected; the feedback circuit 16 is electrically connected with the PWM controller 15 and the constant current constant voltage control circuit 17 respectively; the MCU controller 18 is respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com