Device and method for full mold centrifugal casting of double-plate flange straight tube and wall flange straight tube

A technology of centrifugal casting and flange, which is applied in the field of centrifugal casting, can solve the problems that cannot be completely eliminated, the welding quality cannot be evaluated by users, and the stress concentration in the welding area can achieve the same overall metallographic structure, which is conducive to protecting the environment and alloy The effect of tissue densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

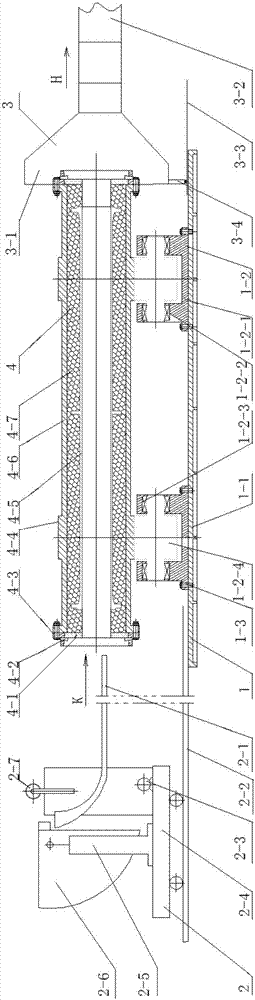

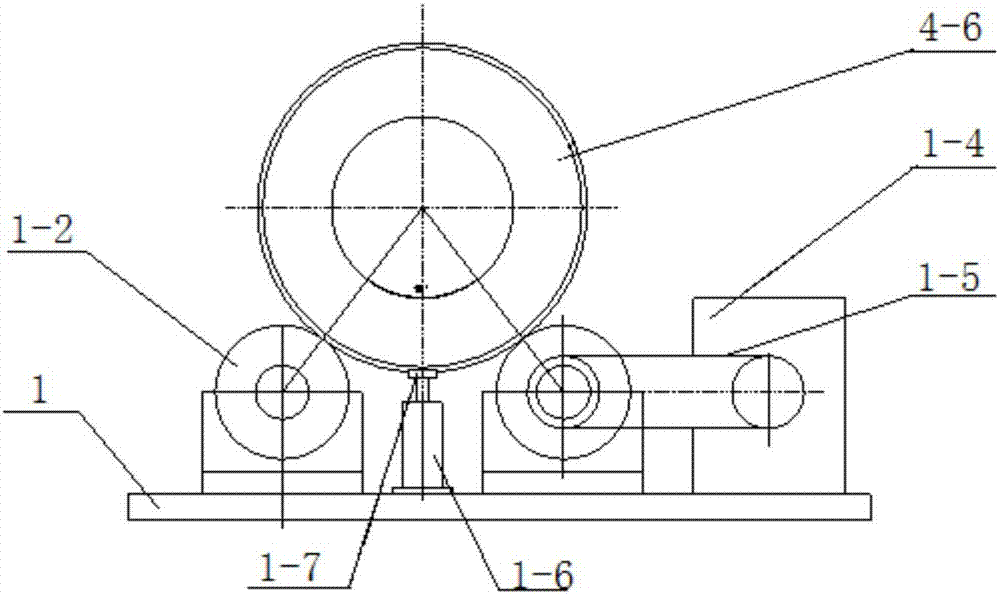

[0071] PN16, length 1.8 meters, DN800 double disc flange straight pipe, 3 pieces of one-type centrifugal casting method with solid type centrifugal centrifugal casting are:

[0072] (1) Model preparation

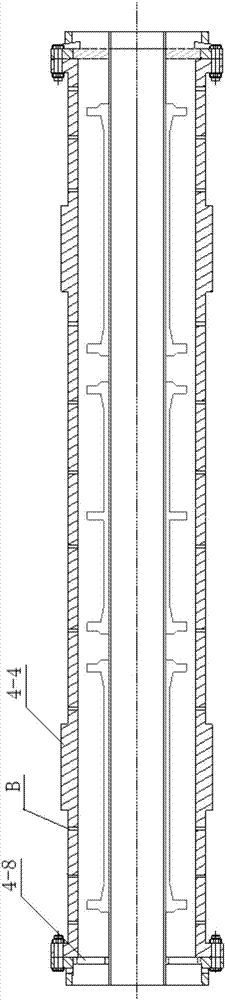

[0073] A. Prepare DN800, PN16 foam plastic molds 4-5 according to user needs. Foam plastic mold 4-5 is that EPS beads pass through pre-foaming, and in special-purpose molding machine, pass through solid type centrifugal casting mold 4 thermoplastic molding. The straight pipe section and the flange are split molded. The characteristic of foam plastic mold 4-5 is that it can be cut and assembled at will, and the PN16 flange and straight pipe are spliced into two semicircles according to the length of 1.8 meters, and three pieces are manufactured respectively;

[0074] B. Install the prepared 3 pieces of foam plastic mold 4-5 on the positioning steel pipe skeleton 4-9. When assembling, pay attention to the distance between the end faces of the 3 pieces of flanges not less t...

Embodiment 2

[0093] Casting PN16, DN200 single-disc wall-through flange straight pipe with a length of 4 meters by using the real-type centrifugal casting method, and the length of the wall-through flange from the flange sealing end is 2 meters. The centrifugal casting method is:

[0094] (1) Model preparation

[0095] A. Prepare DN200, PN16 foam plastic molds 4-5 according to user needs. Foam plastic mold 4-5 is that EPS beads pass through pre-foaming, and in special-purpose molding machine, pass through solid type centrifugal casting mold 4 thermoplastic molding. The straight pipe part is molded with the flange and the through-wall flange. The characteristic of the foam plastic mold 4-5 is that it can be cut and assembled at will. The PN16 flange and the straight pipe are spliced into two semicircles according to the length of 4 meters, and the wall-through flange is fixed at 2 meters from the end face of the flange;

[0096] B. Install the prepared foam plastic mold 4-5 on the posit...

Embodiment 3

[0116] The centrifugal casting method of PN10 with solid type centrifugal centrifugal casting, length 2.5 meters, specifications are DN350, DN400 double-disc flange straight pipe, 2 pieces, one type centrifugal casting method is:

[0117] (1) Model preparation

[0118] A. Prepare DN350, PN10, 2.5 meters in length and 4-5 foam plastic molds in DN400, PN10, 2.5 meters in length according to user requirements. Foam plastic mold 4-5 is that EPS beads pass through pre-foaming, and in special-purpose molding machine, pass through solid type centrifugal casting mold 4 thermoplastic molding. The straight pipe section and the flange are split molded. The characteristic of foam plastic mold 4-5 is that it can be cut, assembled and bonded arbitrarily. The PN10 flange and straight pipe are spliced into two semicircles according to the length of 2.5 meters, and two pieces are manufactured respectively;

[0119] B. Install the prepared 2 pieces of foam plastic mold 4-5 on the positionin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com