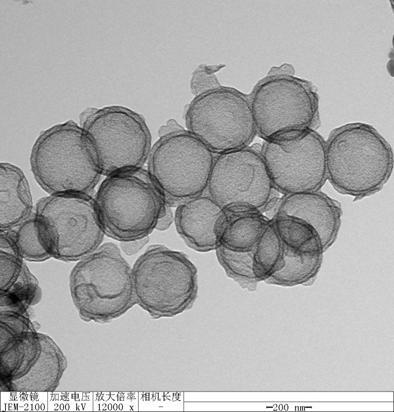

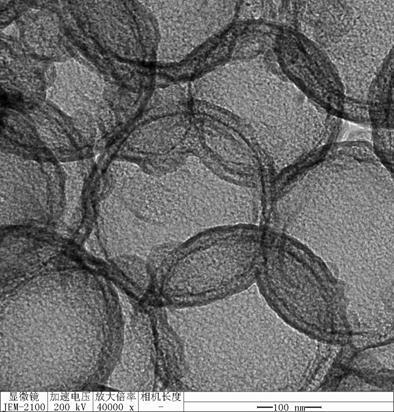

Double-shell different component hollow carbon microsphere with adjustable cavity size and wall thickness

A double-shell, adjustable technology, applied in the field of new materials, can solve the problem of inability to achieve fine control of the diameter, cavity size, wall thickness and composition of hollow carbon microspheres, increase ion diffusion distance, reduce capacitor specific capacity, etc. It can effectively control the cavity size and wall thickness, the preparation process is simple and environmentally friendly, and the size is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

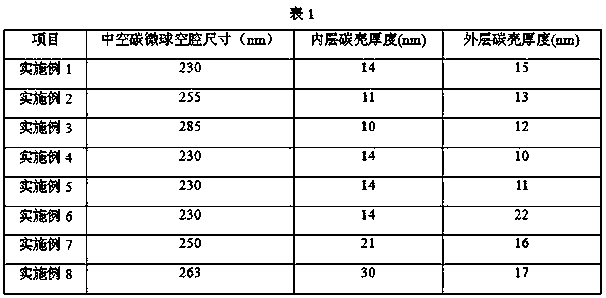

Embodiment 1

[0023] 1) Preparation of soft-core / hard-shell polystyrene (PS) microspheres: Measure 8 mL of styrene, add it dropwise to 120 mL of deionized water, blow in high-purity nitrogen gas and stir for 30 minutes, heat to 70°C, and then add 14 mL A deionized aqueous solution containing 0.16 g of potassium persulfate was used as an initiator, stirred at 70°C for 4 h, and then 1.8 mL of divinylbenzene was added to the above system to continue the reaction for 24 h to obtain a soft-core / hard-shell PS with a diameter of 250 nm. Microspheres.

[0024] 2) Preparation of PS / PDA composite microspheres: take 0.5 g of PS microspheres prepared in step 1) and ultrasonically disperse them in 400 mL of a mixed solvent with a volume ratio of ethanol: water = 7: 1, add 0.25 g of trishydroxyaminomethane and 0.75g of dopamine, mixed and stirred at room temperature for 24 hours, dopamine polymerized on the surface of polystyrene microspheres to obtain PS / PDA composite microspheres.

[0025] 3) Preparat...

Embodiment 2

[0027] 1) Preparation of soft-core / hard-shell polystyrene (PS) microspheres: Measure 8 mL of styrene, add it dropwise to 120 mL of deionized water, blow in high-purity nitrogen gas and stir for 30 minutes, heat to 70°C, and then add 14 mL A deionized aqueous solution containing 0.12 g of potassium persulfate was used as an initiator, stirred at 70°C for 4 h, and then 1.8 mL of divinylbenzene was added to the above system to continue the reaction for 24 h to obtain a soft-core / hard-shell PS with a diameter of 280 nm. Microspheres.

[0028] 2) Preparation of PS / PDA composite microspheres: according to Example 1.

[0029] 3) Preparation of double-shell heterogeneous hollow carbon microspheres: according to Example 1, double-shell heterogeneous hollow carbon microspheres with a cavity size of 255 nm can be obtained.

Embodiment 3

[0031] 1) Preparation of soft-core / hard-shell polystyrene (PS) microspheres: Measure 8 mL of styrene, add it dropwise to 120 mL of deionized water, blow in high-purity nitrogen gas and stir for 30 minutes, heat to 70°C, and then add 14 mL A deionized aqueous solution containing 0.08 g of potassium persulfate was used as an initiator, stirred at 70°C for 4 h, and then 1.8 mL of divinylbenzene was added to the above system to continue the reaction for 24 h to obtain a soft-core / hard-shell PS with a diameter of 320 nm. Microspheres.

[0032] 2) Preparation of PS / PDA composite microspheres: according to Example 1.

[0033] 3) Preparation of double-shell heterogeneous hollow carbon microspheres: according to Example 1, double-shell heterogeneous hollow carbon microspheres with a cavity size of 285 nm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com