A kind of sludge thickening and dehydration treatment method

A treatment method, sludge concentration technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve problems such as short service life, low dehydration efficiency, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

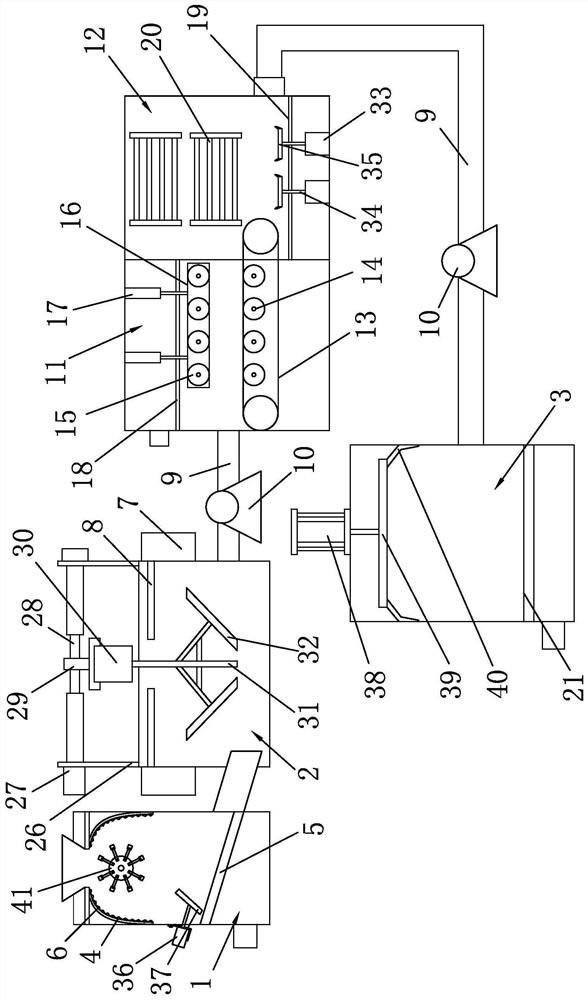

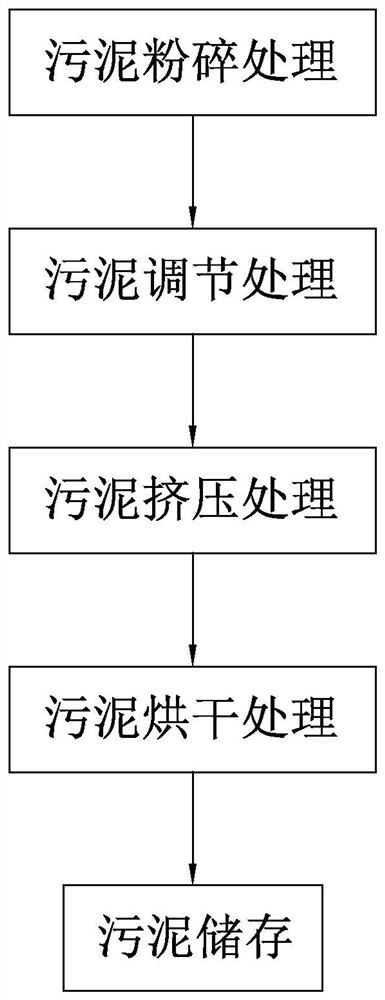

[0040] Such as Figure 1 to Figure 3 Shown, be a kind of sludge concentration dehydration processing method of the present invention, comprise the following steps:

[0041] 1) Sludge crushing treatment:

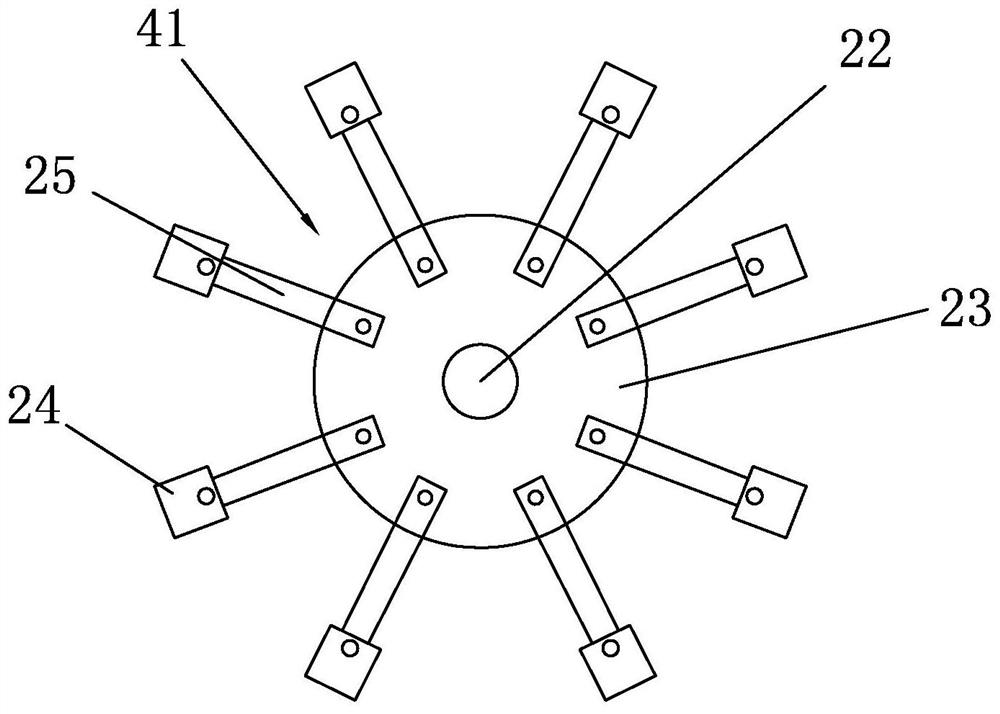

[0042] (1) The sludge to be treated is transported to the sludge dewatering system through the sludge pump for treatment, the sewage entering the sludge dewatering system first enters the crushing chamber 1 for crushing treatment, and the sludge enters from the upper end of the crushing chamber 1 The mud mouth enters the crushing chamber 1, and through the double crushing of the crushing disc 23 and the crushing hammer 24 in the crushing chamber 1, the particulate impurities in the sludge are crushed, and the sewage in the sludge enters the water accumulation chamber from the permeable plate 5, Then it is discharged from the water outlet of the water accumulation chamber, so as to facilitate the subsequent treatment of sludge, and avoid the phenomenon of blockage and damage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com