Acrylic acid pressure-sensitive adhesive and method for preparing same

An acrylic pressure-sensitive adhesive, selected technology, applied in the field of pressure-sensitive adhesives, can solve problems such as high cost, environmental pollution, and high price, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

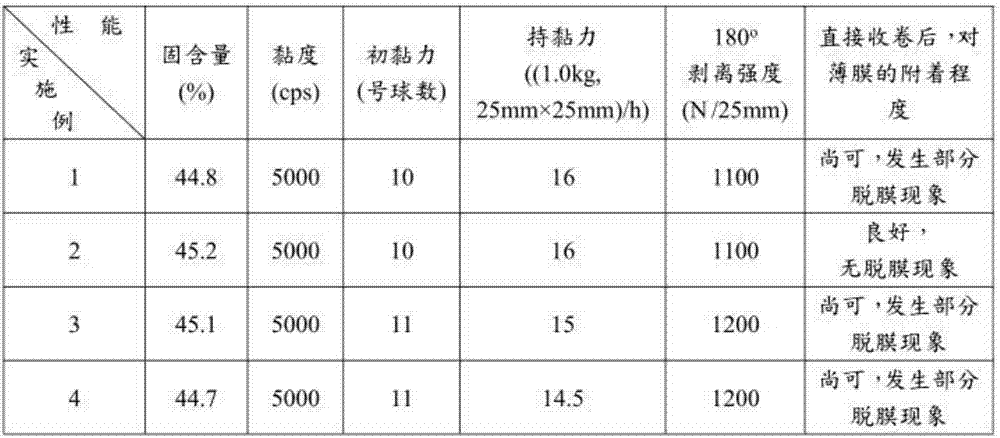

Examples

preparation example Construction

[0034] The present invention also proposes a preparation method of acrylic pressure-sensitive adhesive, comprising the following steps:

[0035] Provide the first part of solvent, the first part of soft monomer, the first part of hard monomer, and the first part of functional monomer to mix and heat;

[0036] providing the first part of the initiator;

[0037] Provide the second part of solvent, the second part of soft monomer, the second part of hard monomer, the second part of functional monomer, and the second part of initiator;

[0038] Provide the third part of initiator, the third part of hard monomer;

[0039] Provide tackifier, the first part of solvent;

[0040] Cool to 50-60°C, provide curing agent, silicone polymer, and the second part of solvent.

[0041] Specifically, (1) Put the first part of the solvent, the first part of the soft monomer, the first part of the hard monomer, and the first part of the functional monomer into a four-necked flask, and heat it to...

Embodiment 1

[0046] Provide 17.6 parts of ethyl acetate, 7.2 parts of methanol, 8.6 parts of isooctyl acrylate, 12.9 parts of butyl acrylate, 0.8 parts of acrylic acid, 0.002 parts of hydroxyethyl acrylate, and 0.001 parts of glycidyl methacrylate, and put them into a four-necked flask. heating to reflux temperature;

[0047] Titrate 0.06 part of azobisisobutyronitrile for 0.5 hours, and keep the temperature at reflux temperature;

[0048] After the titration, keep warm for 0.5 hours;

[0049] Titrate 3 parts of ethyl acetate, 5.5 parts of isooctyl acrylate, 8.7 parts of butyl acrylate, 0.5 parts of acrylic acid, 0.001 parts of hydroxyethyl acrylate, 0.001 parts of glycidyl methacrylate and 0.06 parts of azobisisobutyronitrile for 1.5 hours , the temperature is maintained at the reflux temperature;

[0050] After adding 0.09 parts of azobisisobutyronitrile and 2.3 parts of vinyl acetate, keep warm for 4 hours;

[0051] Add 15.4 parts of ethyl acetate, 2.8 parts of rosin glycol and 2.8 p...

Embodiment 2

[0055] Provide 17.6 parts of ethyl acetate, 7.2 parts of methanol, 8.6 parts of isooctyl acrylate, 12.9 parts of butyl acrylate, 0.8 parts of acrylic acid, 0.002 parts of hydroxyethyl acrylate, and 0.001 parts of glycidyl methacrylate, and put them into a four-necked flask. heating to reflux temperature;

[0056] Titrate 0.06 part of azobisisobutyronitrile for 0.5 hours, and keep the temperature at reflux temperature;

[0057] After the titration, keep warm for 0.5 hours;

[0058] Titrate 3 parts of ethyl acetate, 5.5 parts of isooctyl acrylate, 8.7 parts of butyl acrylate, 0.5 parts of acrylic acid, 0.001 parts of hydroxyethyl acrylate, 0.001 parts of glycidyl methacrylate and 0.06 parts of azobisisobutyronitrile for 1.5 hours , the temperature is maintained at the reflux temperature;

[0059] After adding 0.09 parts of azobisisobutyronitrile and 2.3 parts of vinyl acetate, the mixture was incubated for 4 hours. (6) Stir evenly after dropping into 15.4 parts of ethyl aceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com