Circuit board automatic production management system

A production management system and circuit board technology, which is applied in manufacturing computing systems, electrical digital data processing, data processing applications, etc., can solve the problem of post-recording, circuit board products lack of unique codes, and product summary information cannot be processed in time and other issues to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

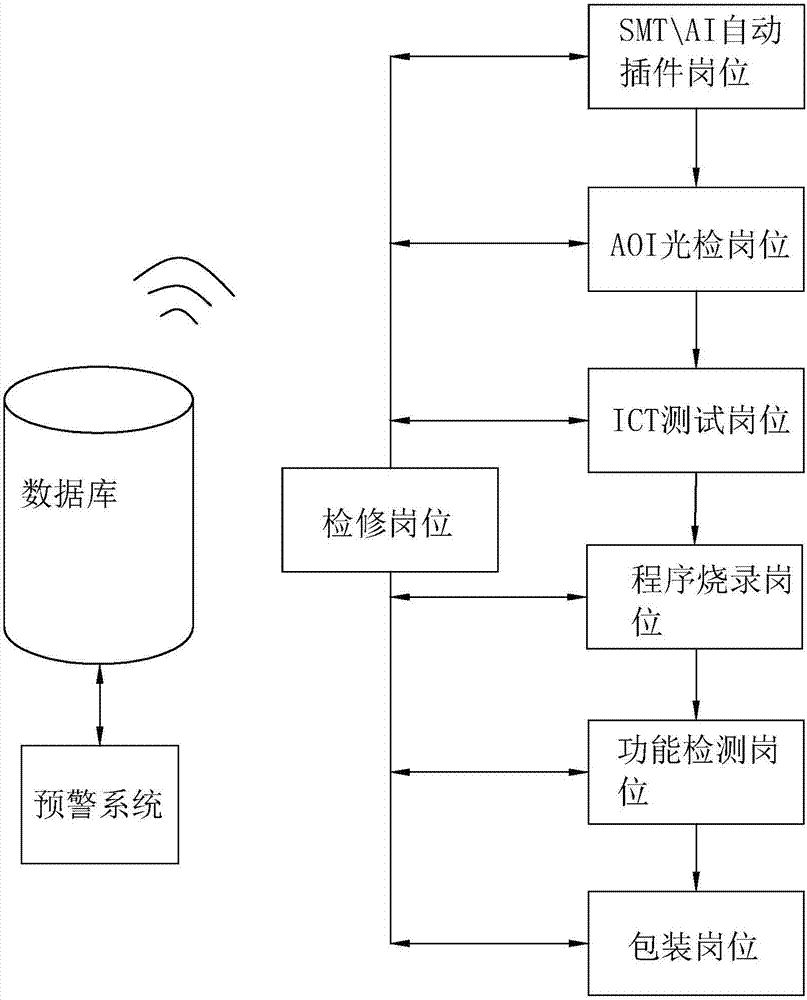

[0014] Embodiment 1, reference figure 1 , a circuit board production line is equipped with SMT (surface mount technology)\AI (plug-in mount technology) automatic plug-in posts, AOI (automatic optical inspection) light inspection posts, ICT test (automatic online tester) posts, program burning posts , function testing posts, maintenance posts and packaging posts, among which SMT\AI automatic plug-in posts, AOI optical inspection posts, ICT testing posts, program burning posts, function testing posts and packaging posts are arranged in sequence in an assembly line, and the maintenance posts are used for maintenance from For the faulty circuit boards in the above positions, after the fault is eliminated, the circuit boards will be returned to the corresponding positions. Each of the above positions is equipped with a scanning gun.

[0015] Each position of the production line is connected to the database through wireless signals. The database includes: a product list and a custom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com