Method for removing welding slag and overlap on inner wall of steel pipeline

A technology for pipelines and welding flashes, which is applied in the field of removing welding slag and welding flashes on the inner wall of steel pipelines, can solve problems such as prolonging the construction period, and achieve the effect of shortening time and cleaning and thorough treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

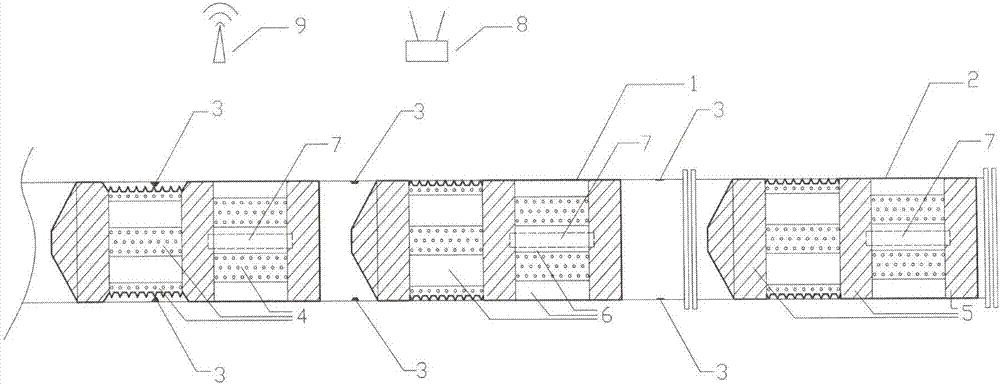

[0029] see figure 1 , a method for removing welding slag and welding tumors on the inner wall of a steel pipeline, the specific steps are as follows:

[0030] 1. Detect the inner diameter of the pipeline 1, and process the dynamic seal support assembly 5 according to the inner diameter of the pipeline 1. The dynamic seal support assembly 5 is prefabricated with rubber material with good elasticity and good wear resistance, and the diameter of the dynamic seal support assembly 5 is excessive. The amount is 1.5-5% of the inner diameter of the pipeline 1; processing the filing and grinding elastic component 6, the filing and grinding elastic component 6 is made of spring steel with good elasticity, and the elastic force is 30-50kg; Grinding knife 4 is made of hard and wear-resistant tool steel material, and the radius of curvature of the toothed arc surface of grinding knife grinding knife 4 is equal to that of the inner wall of pipeline 1; assembled and combined tumor removal de...

Embodiment 2

[0037] see figure 1 , a method for removing welding slag and welding tumors on the inner wall of a steel pipeline, the specific steps are as follows:

[0038]1. Detect the inner diameter of the pipeline 1, and process the dynamic seal support assembly 5 according to the inner diameter of the pipeline 1. The dynamic seal support assembly 5 is prefabricated with polyurethane material with good elasticity and good wear resistance, and the diameter of the dynamic seal support assembly 5 is excessive. The amount is 1.5-5% of the inner diameter of the pipeline 1; processing the filing and grinding elastic component 6, the filing and grinding elastic component 6 is made of stainless steel with good elasticity, and the elasticity is 30-50kg; Knife 4 is made of hard and wear-resistant alloy steel, and the radius of curvature of the toothed arc surface of knife grinding knife 4 is equal to that of the inner wall of pipeline 1; Assembled and combined tumor removal device: install dynamic...

Embodiment 3

[0045] see figure 1 , a method for removing welding slag and welding tumors on the inner wall of a steel pipeline, the specific steps are as follows:

[0046] 1. Detect the inner diameter of the pipeline 1. According to the inner diameter of the pipeline 1, process the dynamic seal support component 5. The dynamic seal support component 5 is prefabricated with polyurethane material with good elasticity and good wear resistance. The shape of the dynamic seal support component 5 is the sealing performance. Good rubber disc or rubber bowl shape, the diameter interference of the dynamic seal support component 5 is 1.5-5% of the inner diameter of the pipeline 1; processing and filing the elastic component 6, the filing elastic component 6 is made of beryllium bronze with good elasticity, Elasticity 30-50kg; processing toothed arc surface grinder 4, toothed arc surface grinder 4 is made of hard and wear-resistant diamond material, toothed arc surface grinder 4 grinds the radius of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com