Plate electrode for electrolyzing water

An electrode plate and electrolyzed water technology, applied in the field of electrolyzed water, can solve the problems of high processing and production costs, many and complicated manufacturing processes, and achieve the effect of saving manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

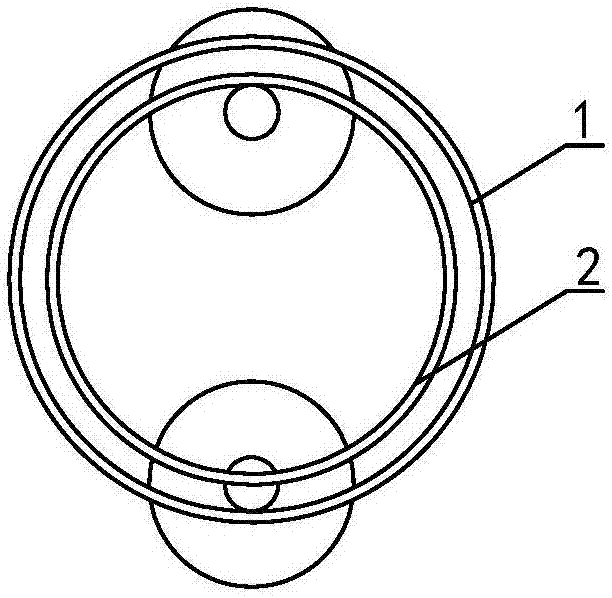

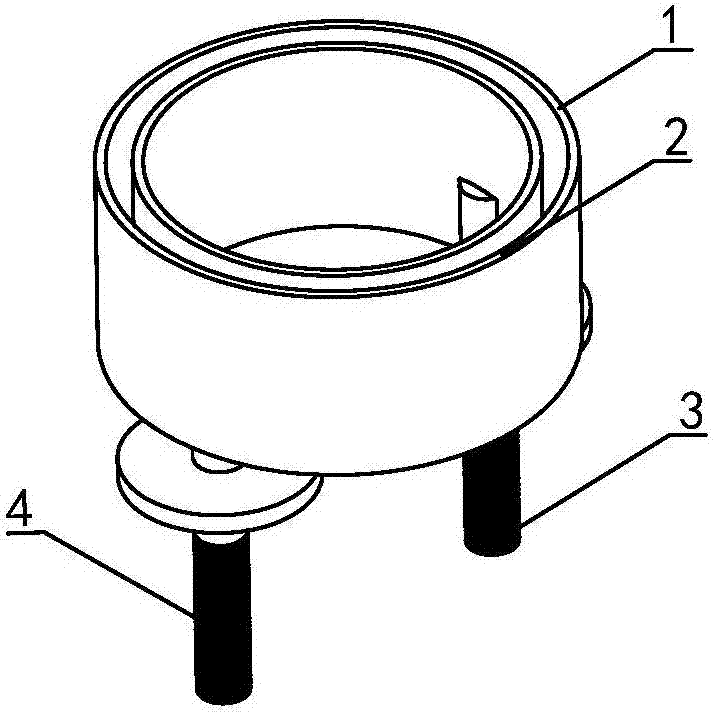

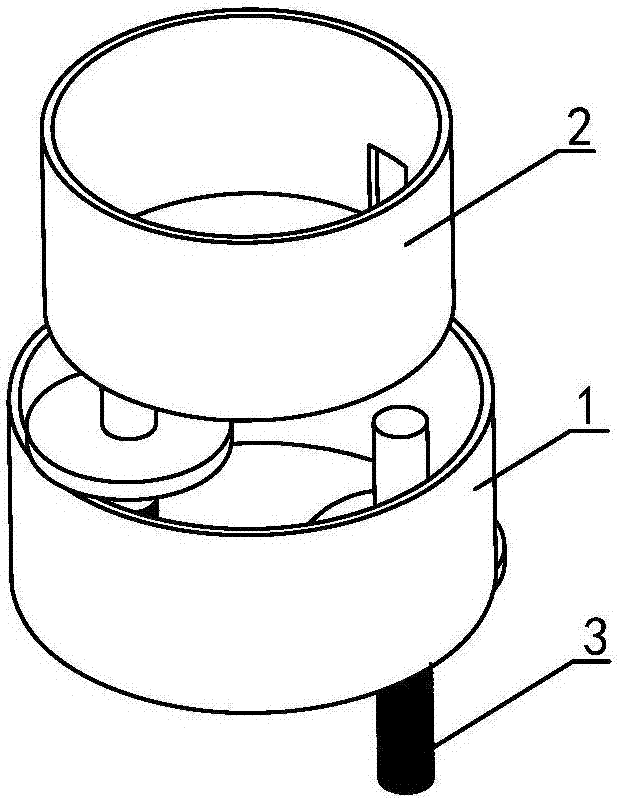

[0035] Such as Figure 1-3 As shown, the electrolyzed water electrode plate described in the embodiment of the present invention is composed of an outer pole plate 1, an inner pole plate 2, an outer pole plate conductive column 3 and an inner pole plate conductive pole 4, and the outer pole plate Both the plate 1 and the inner layer plate 2 are composed of a cylindrical tube body, and the side wall of each tube body is welded with a corresponding conductive column, thereby forming the outer layer electrode plate conductive column 3 and the inner layer electrode plate conductive column 4. The distance between the outer pole plate 1 and the inner pole plate 2 is any value between 2-10mm, and the height of the outer pole plate 1 or the inner pole plate 2 is any value between 10-150mm;

[0036] Further, both the outer pole plate 1 and the inner pole plate 2 are formed pipes and then cut into required cylinder lengths through the cross-section, and then the conductive connecting co...

Embodiment 2

[0040] Such as Figure 4-6 As shown, the square electrolyzed water electrode plate described in the embodiment of the present invention is composed of a square outer pole plate 11, a square inner pole plate 22 and respective pole plate conductive columns, the square outer pole plate 11 and the square inner pole plate 22 Both are composed of rectangular parallelepiped tubes with openings on the upper and lower bottom surfaces. The side walls of each tube body are welded with corresponding conductive columns, thereby forming the outer plate conductive column 3 and the inner layer conductive column 4. The square outer plate The distance between 11 and the square inner pole plate 22 is any value between 2-10mm, and the height of the square outer pole plate 11 or the square inner pole plate 22 is any value between 10-150mm;

[0041] Further, both the square outer pole plate 11 and the square inner pole plate 22 are cut into the required cuboid height by cross-section of the formed ...

Embodiment 3

[0045] Such as Figure 7-9 As shown, the polygonal electrolyzed water electrode plate described in the embodiment of the present invention is composed of a polygonal outer pole plate 111, a polygonal inner pole plate 222 and respective pole plate conductive columns. The above-mentioned polygons and the polygons described below are in this embodiment Taking the regular hexagon as an example: the polygonal outer pole plate 111 and the polygonal inner pole plate 222 are composed of polyhedron-shaped tubes with upper and lower bottom surfaces open, and the side walls of each tube body are welded with corresponding conductive columns to form the outer layer The pole plate conductive column 3 and the inner layer pole plate conductive column 4, the distance between the polygonal outer pole plate 111 and the polygonal inner pole plate 222 is any value between 2-10mm, the polygonal outer pole plate 111 or the polygonal inner pole The height of the plate 222 is any value between 10-150m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com