Finger like slug flow dissipation and separation device

A separation device and slug flow technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as ineffective treatment of slug flow, large pressure loss of multiphase flow, and unstable separation process , to achieve good impact resistance, ensure safe development, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

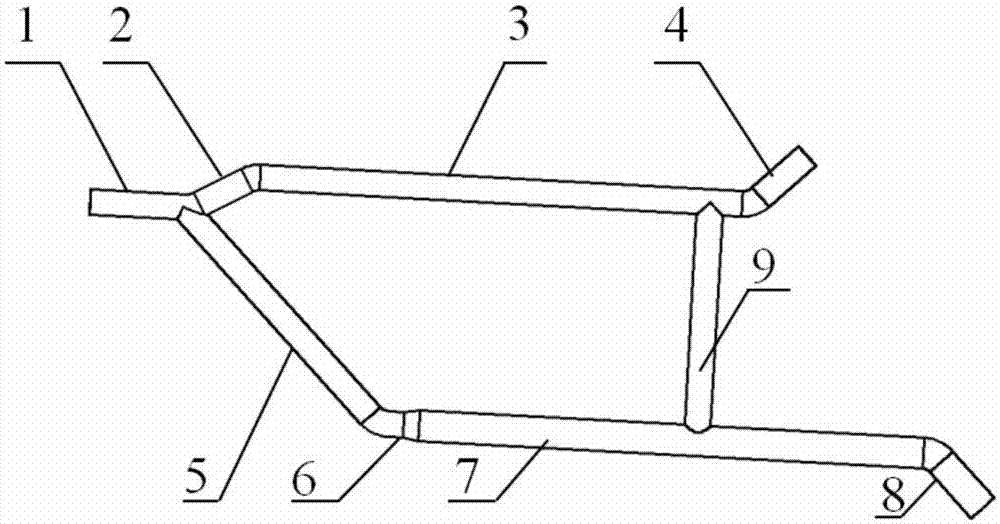

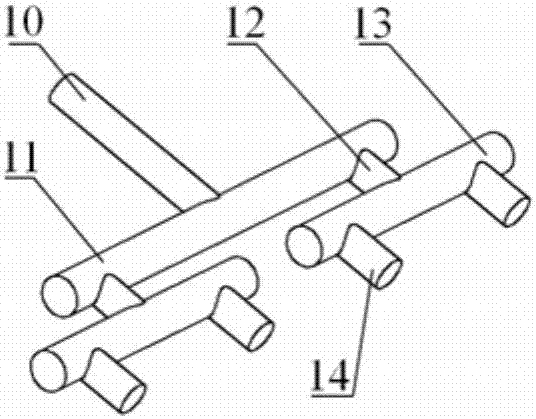

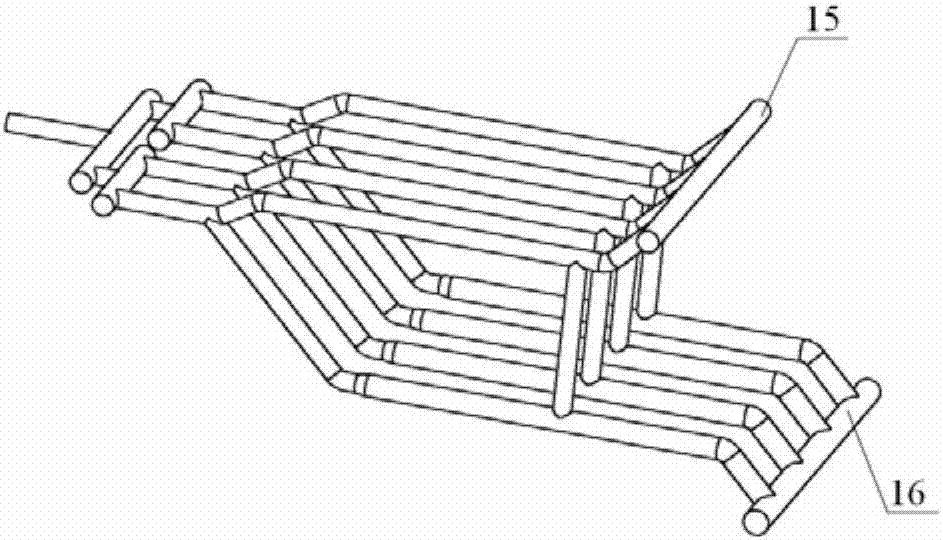

[0023] See attached figure 1 , 2 , 3, a finger-shaped slug flow dissipation separation device is characterized in that it includes an inlet shunt pipe, a finger branch pipe, a gas collection manifold and a liquid collection manifold, including: a finger-shaped inlet pipe 1, an updipping pipe 2, Gas phase jacking pipe 3, upward inclined gas phase outlet pipe 4, downward inclined pipe 5, diameter expansion pipe 6, liquid phase bottom pipe 7, downward inclined liquid phase outlet pipe 8, standpipe 9, diversion inlet pipe 10, primary diversion manifold 11. Primary diversion outlet pipe 12, secondary diversion manifold 13, secondary diversion outlet pipe 14, gas collection manifold 15, liquid collection manifold 16, etc.

[0024] as attached figure 1 As shown, the finger-shaped inlet pipe 1 is connected with the up-dip pipe 2 and the down-dip pipe 5 to form a Y-shaped pipe structure. Since the down-dip pipe 5 is downward and the up-dip pipe 2 is upward, the two-phase flow enterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com