Fully automatic lcd detection control system and method based on aoi technology

A detection control system, fully automated technology, applied in the direction of electrical program control, program control in sequence/logic controller, instruments, etc., to achieve the effect of easy implementation, high practicability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

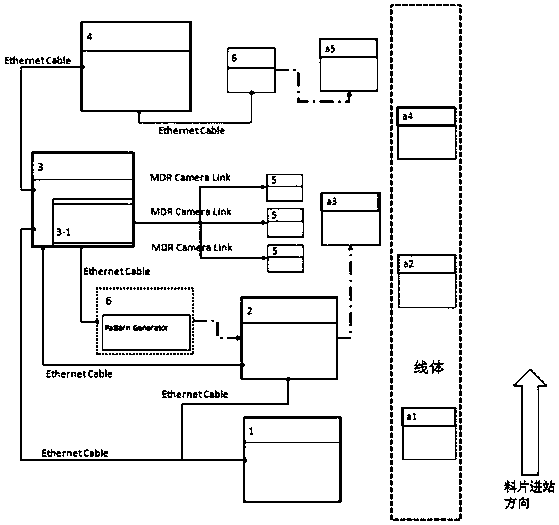

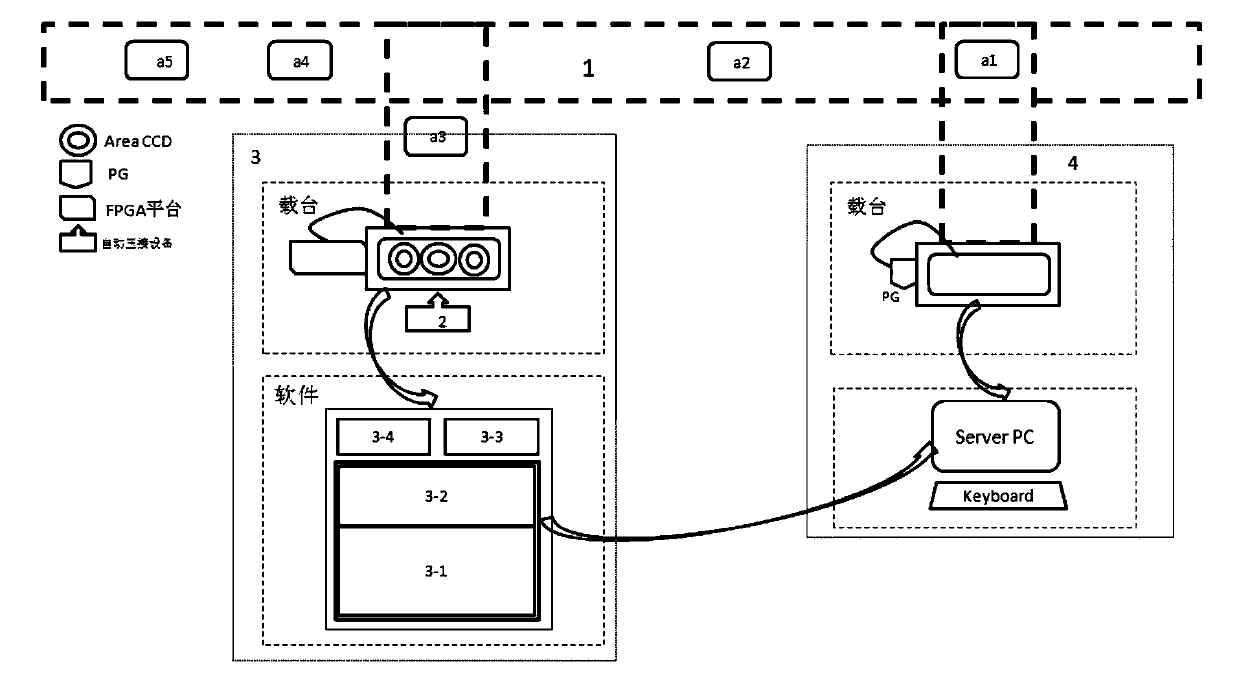

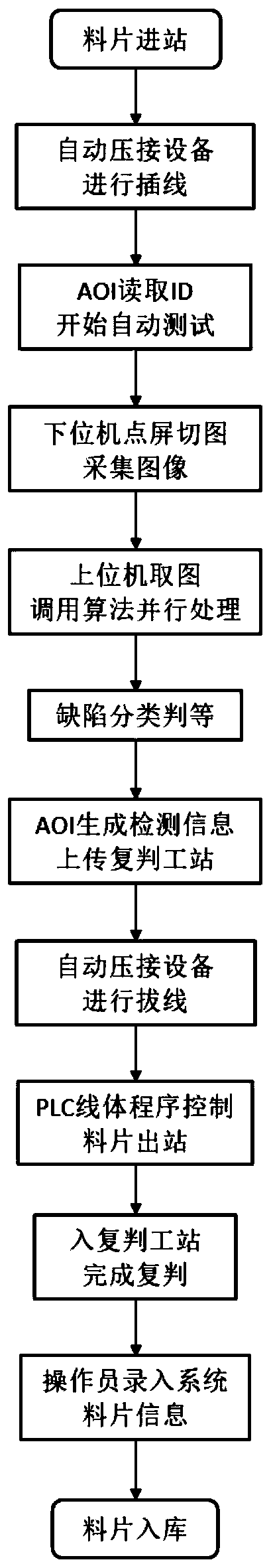

[0039] Such as figure 1 and figure 2 As shown, a fully automatic LCD detection and control system based on AOI technology in the present invention includes an Inline line body PLC control module 1 and a detection workstation. The detection workstation is provided with an automatic crimping device 2, an AOI system 3 and a re-judgment workstation 4.

[0040] Inline PLC control module 1 is used to control the position of LCD panel a3 on the assembly line, and send the panel information to automatic crimping equipment 2 and AOI system 3 . The PLC control module 1 of the Inline line realizes automation through PLC, controls the inbound and outbound of the LCD panel a3 (a1 / a2 / a4 / a5), and carries and transmits the relevant information of the LCD panel a3, when the LCD panel a3 enters the detection workstation , the PLC control module 1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com