Passive exhaust device with storage batteries at intervals

A technology of exhaust device and storage battery, which is applied in the field of electric power, can solve the problems of reducing system reliability and system complexity, and achieve the effect of promoting hydrogen and heat discharge, simple equipment, and strong automatic adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

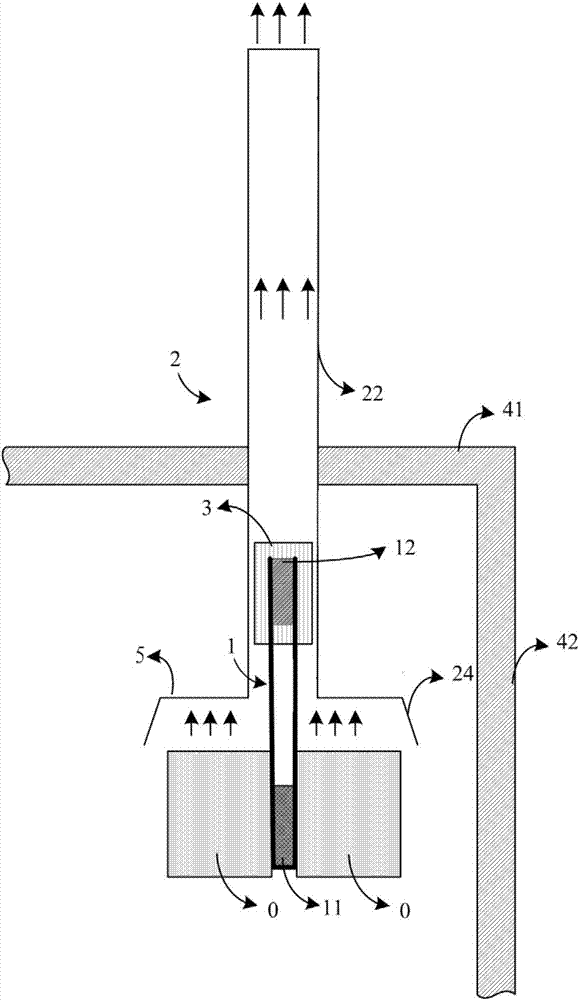

[0023] like figure 1 As shown, the passive exhaust device for the battery compartment includes a heat pipe 1 , an exhaust pipe 2 , an air collecting hood 5 connected to the lower end of the exhaust pipe 2 , and a radiator 3 sleeved on the heat pipe 1 .

[0024] The heat pipe 1 has an evaporation section 11 and a condensation section 12, the evaporation section 11 of the heat pipe 1 is connected to the battery 0, the exhaust pipe 2 has an air inlet and an exhaust port, and the exhaust pipe 2 has a vertical The vertical section 22 provided, the vertical section 22 is set on the upper top plate 41 of the compartment, the air inlet is located at the lower end of the vertical section 22, and the exhaust port is located at the upper end of the vertical section 22, said The exhaust port of the exhaust pipe 2 is connected to the outside atmosphere of the storage battery 0 compartment and an air collecting hood 5 is arranged on its air inlet, and the air collecting hood 5 is arranged o...

Embodiment 2

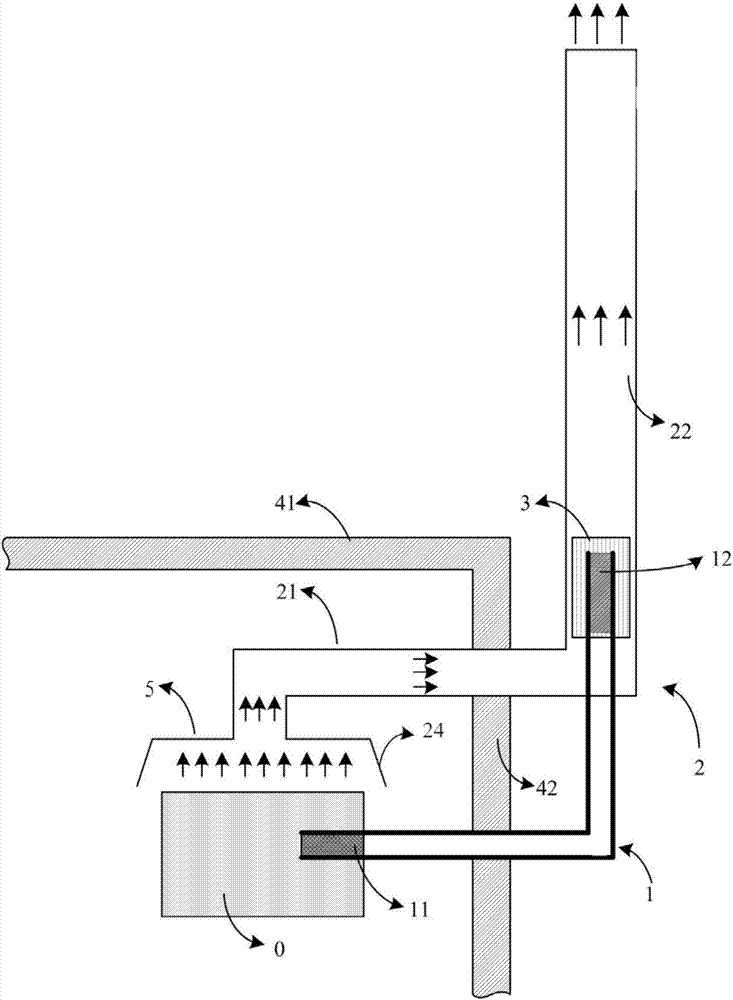

[0026] like figure 2 As shown, the passive exhaust device for the battery compartment includes a heat pipe 1 , an exhaust pipe 2 , an air collecting hood 5 connected to the lower end of the exhaust pipe 2 , and a radiator 3 sleeved on the heat pipe 1 .

[0027] The heat pipe 1 has an evaporating section 11 and a condensing section 12. The evaporating section 11 of the heat pipe 1 is arranged in the battery 0. According to the space conditions of the compartment, the exhaust pipe 2 may be arranged on the side wall 42 of the compartment. The exhaust pipe 2 includes a vertical section 22 arranged vertically and a transverse section 21 connected below the vertical section 22 and arranged horizontally. The transverse section 21 is penetrated on the side wall 42. The exhaust pipe 2 has Air port and exhaust port, the exhaust port is located at the upper end of the vertical section 22, the air inlet is located at the free end of the transverse section 21, the exhaust port of the exha...

Embodiment 3

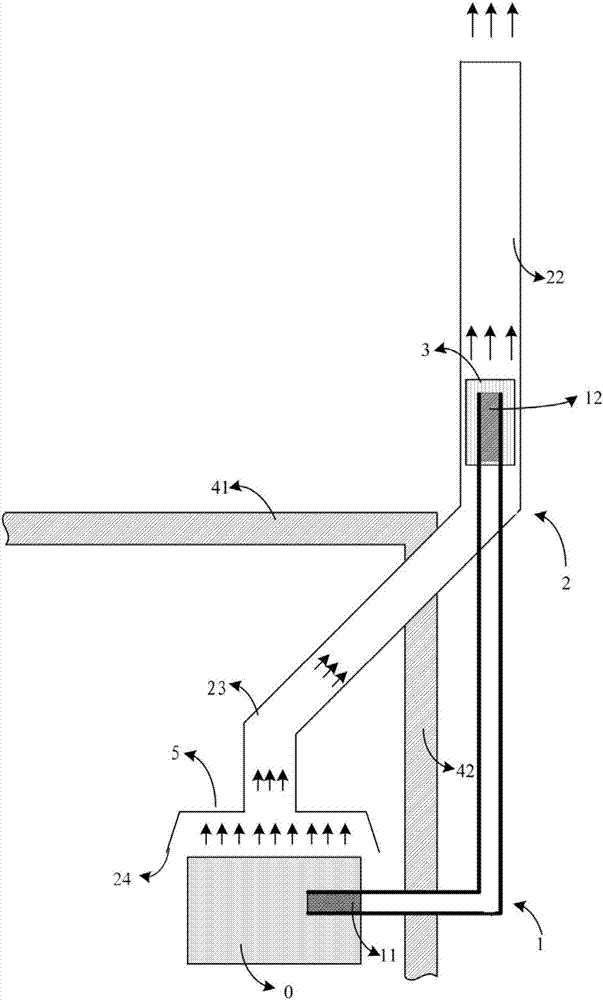

[0029] like image 3 As shown, the passive exhaust device for the battery compartment includes a heat pipe 1 , an exhaust pipe 2 , an air collecting hood 5 connected to the lower end of the exhaust pipe 2 , and a radiator 3 sleeved on the heat pipe 1 .

[0030] The heat pipe 1 has an evaporating section 11 and a condensing section 12. The evaporating section 11 of the heat pipe 1 is arranged in the battery 0. According to the space conditions of the compartment, the exhaust pipe 2 may be arranged on the side wall 42 of the compartment. The exhaust pipe 2 includes a vertical section 22 arranged vertically and an oblique section 23 connected below the vertical section 22 and arranged obliquely. The oblique section 23 is penetrated on the side wall 42. There is an air inlet and an air outlet, the air outlet is arranged at the upper end of the vertical section 22, the air inlet is arranged at the free end of the oblique section 23, and the air outlet of the exhaust pipe 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com