Microwave oven magnetron power supply device with pull-up active clamping branch

A technology of power supply device and magnetron, which is applied in the field of electricity, can solve the problems of burnout of the upper and lower switch tubes of the bridge arm, high power supply cost, and increased loss, and achieve the effect of constant power control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

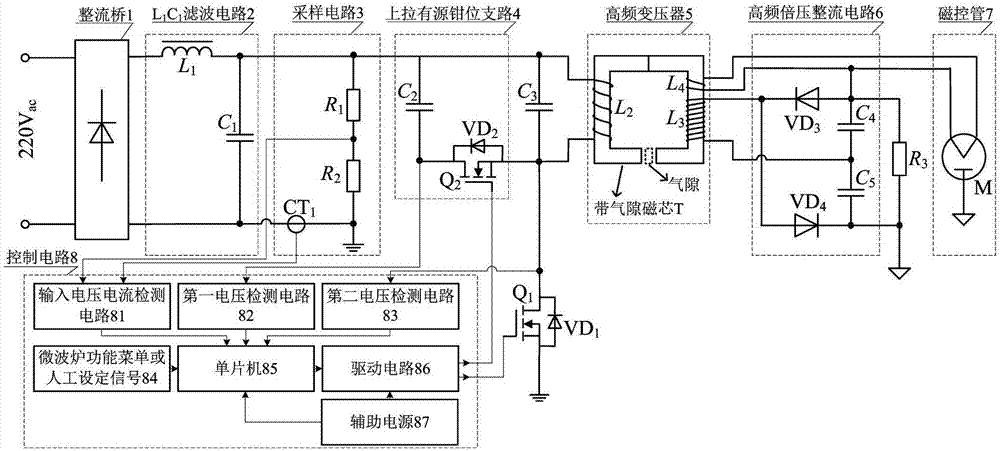

[0020] The main structure of the microwave oven magnetron power supply device with a pull-up active clamping branch described in this embodiment includes a rectifier bridge 1, L 1 C 1Filter circuit 2, sampling circuit 3, pull-up active clamping branch 4, resonant capacitor C 3 , main switching tube Q 1 , the first diode VD 1 , High-frequency transformer 5, High-frequency voltage doubler rectifier circuit 6, Discharge resistor R 3 , magnetron 7 and control circuit 8, the first diode VD 1 main switch Q 1 Anti-parallel diodes, single-phase power frequency alternating current through the rectifier bridge 1, L 1 C 1 After filter circuit 2, it is converted into direct current, and the main switching tube Q 1 , the first diode VD 1 and the pull-up active clamping branch 4 to invert the direct current into high-frequency alternating current, and this high-frequency alternating current is applied to the primary winding L of the high-frequency transformer 5 2 Both ends, after b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com