Laser processing machine

A laser processing machine and laser processing head technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of expensive, material-intensive manufacturing, etc., to reduce the impact of damage, simplify the structure, and reduce the risk of damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

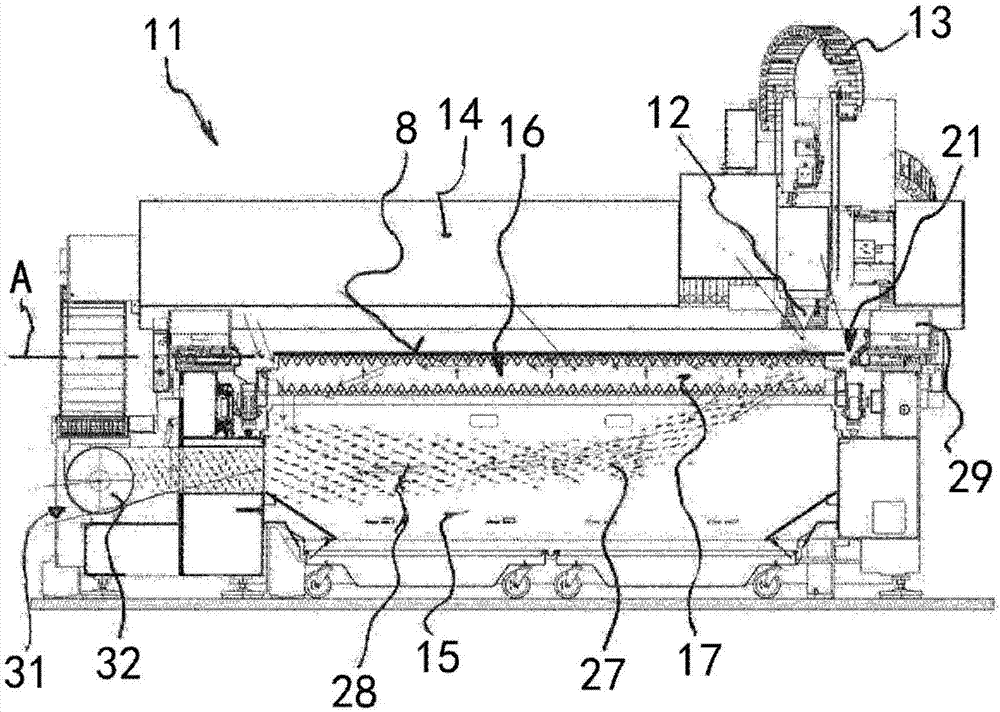

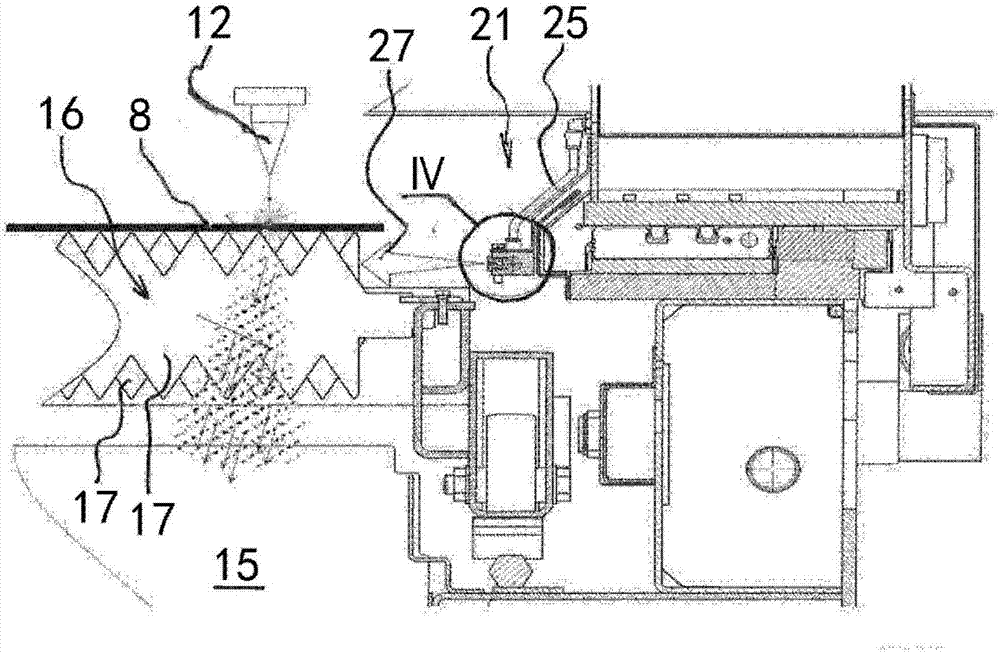

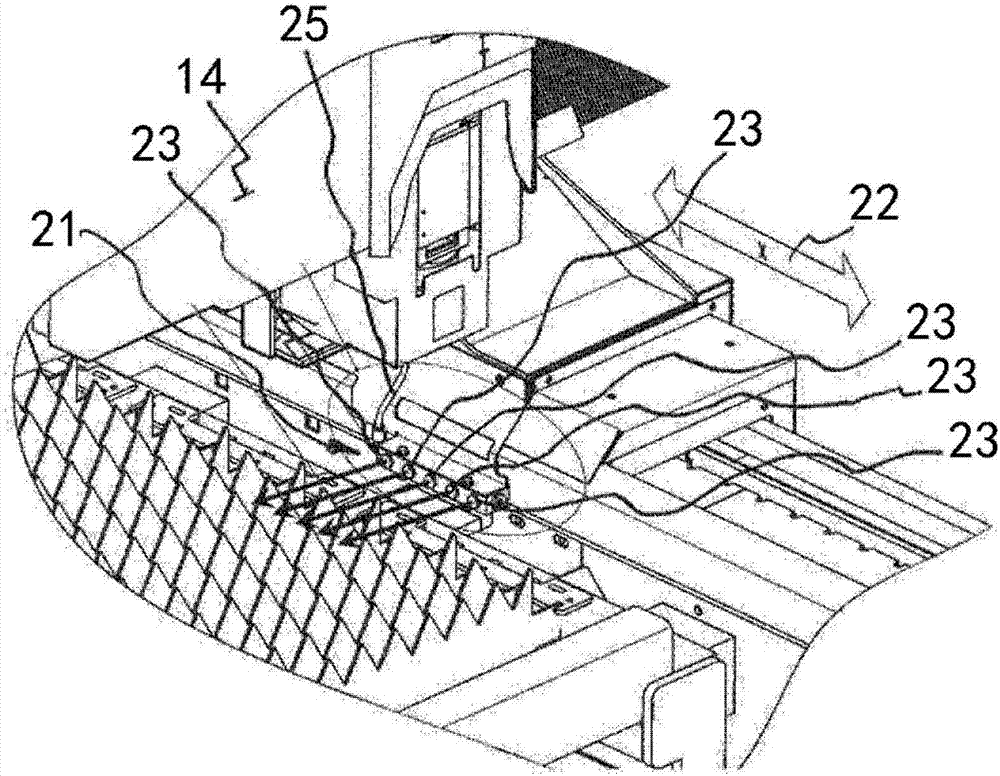

[0076] Figure 1 to Figure 3 The laser processing machine 11 shown is a laser cutting machine with a laser cutting head 12 as a laser processing head. The laser processing machine 11 also includes a dust collection space 15 covered by a support grid 16 . The support grid 16 defines a support plane A for supporting the workpiece 8 to be machined. The support grid 16 comprises a plurality of grid elements 17 parallel to each other and spaced apart from each other.

[0077] The laser cutting head 12 is arranged on a bridge 14 . In order to position the laser cutting head 12 relative to the workpiece 8 , the workpiece 8 can be moved along the bridge 14 and with this bridge 14 in the direction of movement of the laser cutting head 12 (double arrow). Energy is supplied to the laser cutting head 12 through a flexible feeder 13 (also referred to as a supply chain).

[0078] Also provided are fluid supply means 21 and fluid removal means 31, which are designed to create, below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com