Catalyst for decomposing hydrogen peroxide as well as preparation method and use method of catalyst

A technology for hydrogen peroxide and catalyst, which is applied to the catalyst for decomposing hydrogen peroxide and the fields of its preparation and use, can solve the problems of fast catalytic rate and difficult control, and achieve the effects of convenient access, fast catalytic rate and stable catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a catalyst for decomposing hydrogen peroxide, the raw material of which includes an active component and a catalyst carrier, and the active component includes Al 2 o 3 , SiO 2 , CeO 2 , ZrO 2 , MgO, La 2 o 3 、TiO 2 , F 2 、Nd 2 o 3 and Fe 2 o 3 , the catalyst support includes CaO, PdO, HfO 2 ,P 2 o 5 、K 2 O, HCl, Rh, ZnO and As 2 o 3 , the amount of each component in the active component and the catalyst carrier is shown in Table 2.

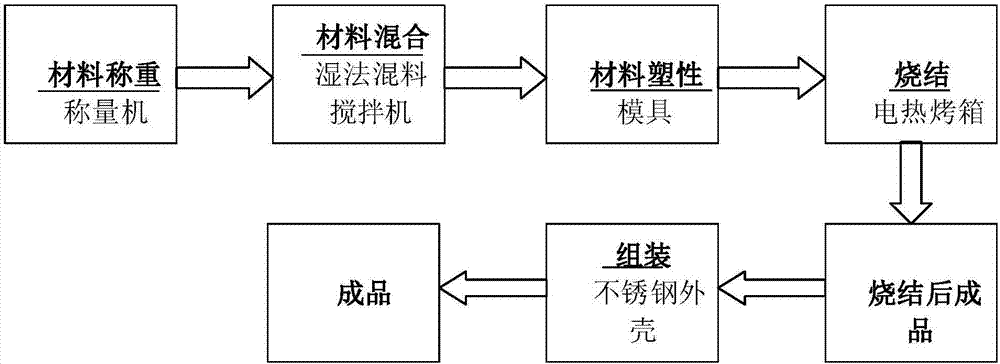

[0036] The preparation method of the catalyst comprises the following steps: after weighing each raw material, mixing them evenly in a wet mixing mixer, placing them in a mold, and then sintering them in an electric oven at a high temperature of 1000° C. to form a porous ceramic cured product. The structure size of the sintered porous ceramic cured product was measured, and the mesh size was 10 mesh. figure 1 It is a flow chart of the preparation process of the catalyst in this example.

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com