A beneficiation process for reducing zinc content in lead concentrate

A lead concentrate, zinc content technology, applied in flotation, solid separation, chemical instruments and methods, etc., can solve the problems of inability to use directly, Zn resources are not used, lead smelting, etc. Valuable metal loss risk, the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

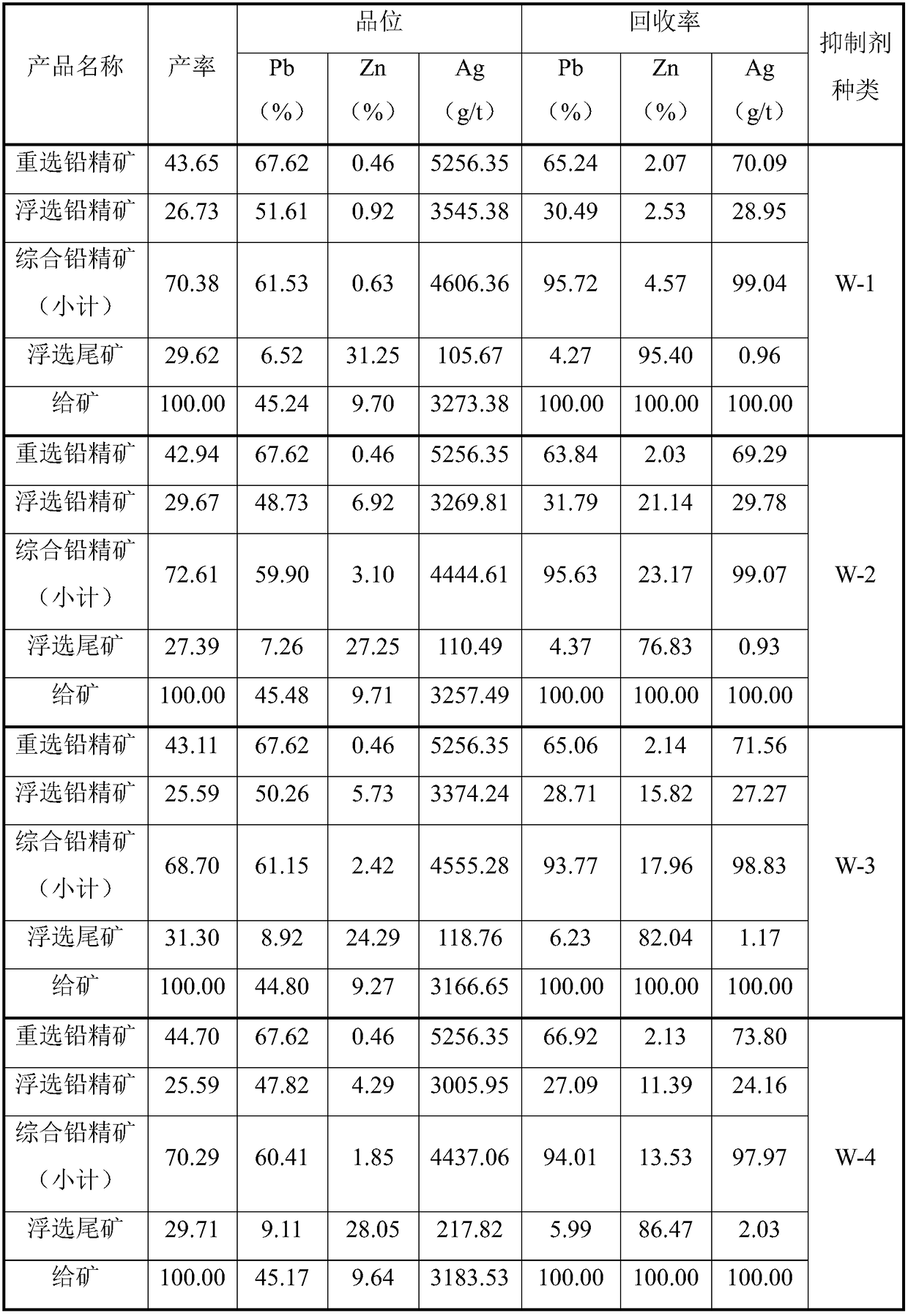

[0045] The raw ore of the lead concentrate processed in this embodiment is a lead-zinc-silver polymetallic mine in Zhalantun, Inner Mongolia. The lead concentrate captured by flotation under the dixanthate collector system contains 9.61% Zn in the concentrate. Containing Pb is 45.91%. The main components are as follows: (in this application, unless otherwise specified, each percentage is a mass percentage)

[0046] Table 1 Analysis results of main chemical elements of flotation lead concentrate

[0047] element

Pb

Zn

Ag

S

Fe

content / %

45.91

9.61

3215g / t

20.52

15.25

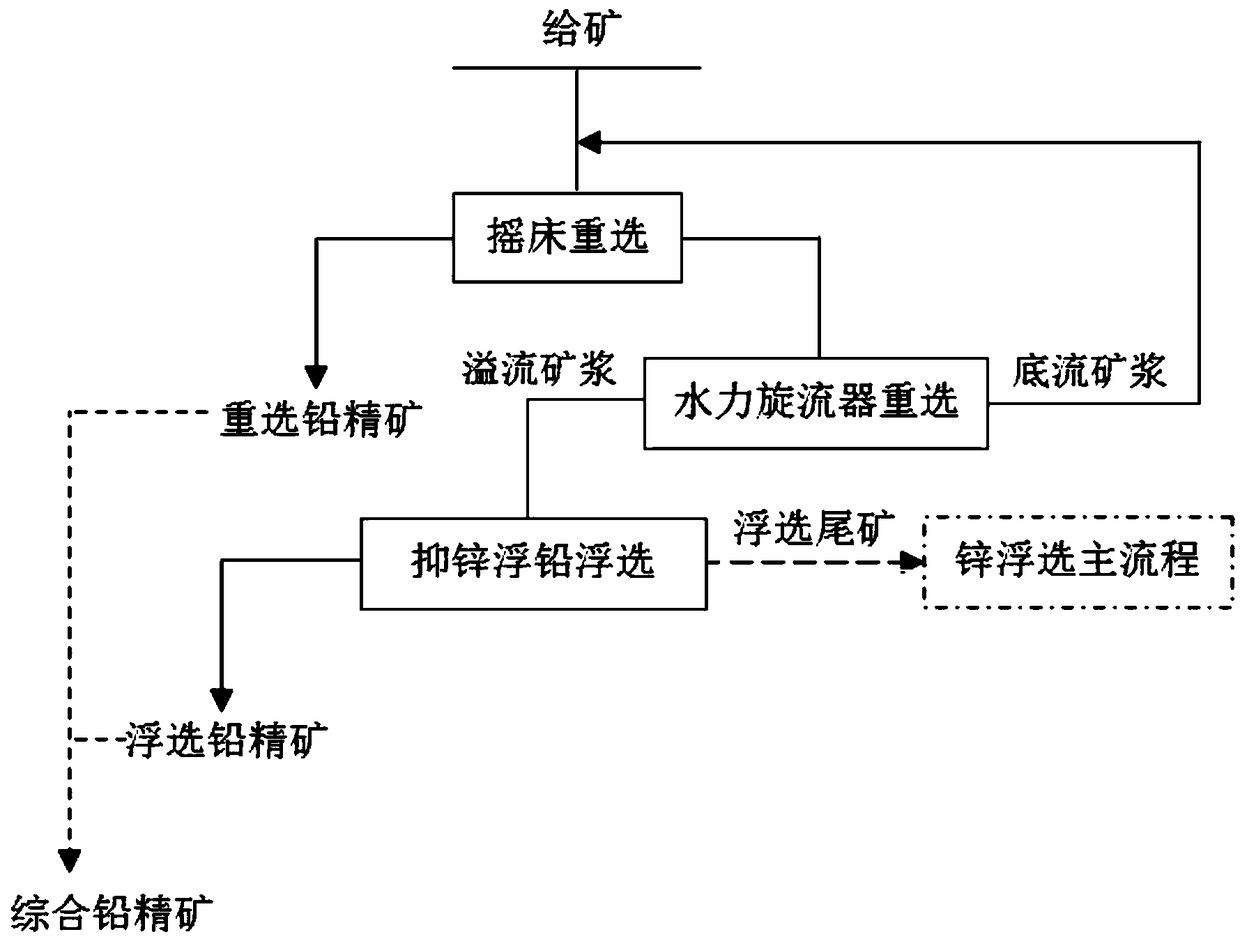

[0048] For the above-mentioned lead concentrate, the technological process used in this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0049] (1) Shaking table gravity separation is carried out to the ore, and the pulp concentration (the ratio of dry ore weight to water) of the feeding ore reselected by the shaking table i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com