High-temperature-resistant photochromic TPU film and preparation method thereof

A photochromic and high temperature resistant technology, applied in the field of polymer materials, can solve the problems of poor controllability of polymerization degree, difficult application, uncontrollable color change, etc., and achieve good physical properties, enhanced photosensitivity, and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

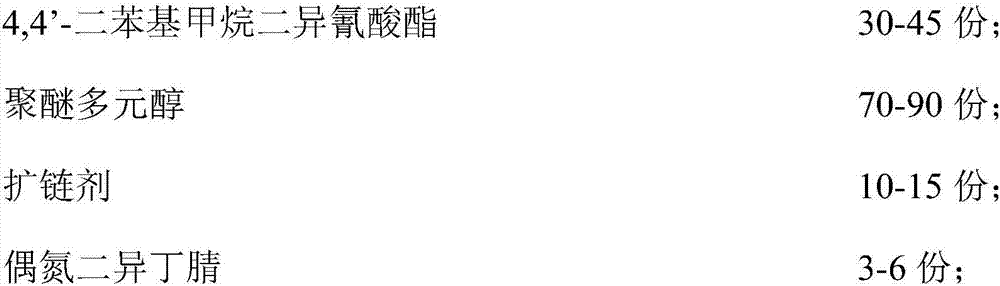

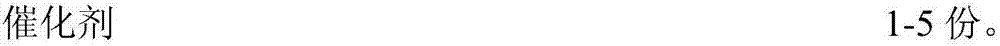

[0044] A kind of preparation method of high temperature resistant photochromic TPU film, described method comprises the following steps:

[0045] (1) Add 70 parts of polyether polyol (number average molecular weight 3500) and 30 parts of 4,4'-diphenylmethane diisocyanate into the container in sequence, stir at a speed of 500r / min, and vacuumize at 50°C to -0.4kPa, get the prepolymer;

[0046] (2) Add 10 parts of chain extender and 1 part of catalyst in the formula amount to the prepolymer obtained in step (1), and continue to react at 70° C. for 2 hours;

[0047] (3) Add 6 parts of azobisisobutyronitrile to the reacted material in step (2), stir for 1h at a speed of 500r / min, then join in the twin-screw extruder, set the twin-screw extruder The temperature of the feeding section is 130°C, the temperature of the mixing section is 150°C, the temperature of the extrusion section is 170°C, and the temperature of the head section is 170°C. Extrusion molding obtains a high temperat...

Embodiment 2

[0049] A kind of preparation method of high temperature resistant photochromic TPU film, described method comprises the following steps:

[0050] (1) Add 86 parts of polyether polyol (number average molecular weight 3200) and 42 parts of 4,4'-diphenylmethane diisocyanate into the container in sequence, stir at a speed of 1000r / min, and vacuumize at 58°C to -0.35kPa, obtain prepolymer;

[0051] (2) Add 14 parts of chain extender and 2 parts of catalyst in the formula amount to the prepolymer obtained in step (1), and continue to react at 78°C for 3.5h;

[0052] (3) Add 5.5 parts of azobisisobutyronitrile to the reacted material in step (2), stir for 1.8h at a speed of 1000r / min, then add to the twin-screw extruder, set the twin-screw extruder The temperature of the feeding section of the machine is 138°C, the temperature of the mixing section is 158°C, the temperature of the extrusion section is 178°C, and the temperature of the head section is 178°C, and the high temperature ...

Embodiment 3

[0054] A kind of preparation method of high temperature resistant photochromic TPU film, described method comprises the following steps:

[0055] (1) Add 82 parts of polyether polyol (number average molecular weight 3800) and 38 parts of 4,4'-diphenylmethane diisocyanate into the container in sequence, stir at a speed of 900r / min, and vacuumize at 55°C to -0.3kPa, get the prepolymer;

[0056] (2) Add 13 parts of chain extender and 3 parts of catalyst in the formula amount to the prepolymer obtained in step (1), and continue to react at 75° C. for 3 h;

[0057] (3) Add 5 parts of azobisisobutyronitrile to the reacted material in step (2), stir for 1.5h at a speed of 900r / min, then join in the twin-screw extruder, set the twin-screw extruder The temperature of the feeding section of the machine is 135°C, the temperature of the mixing section is 155°C, the temperature of the extrusion section is 175°C, and the temperature of the head section is 175°C, and the high temperature re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com